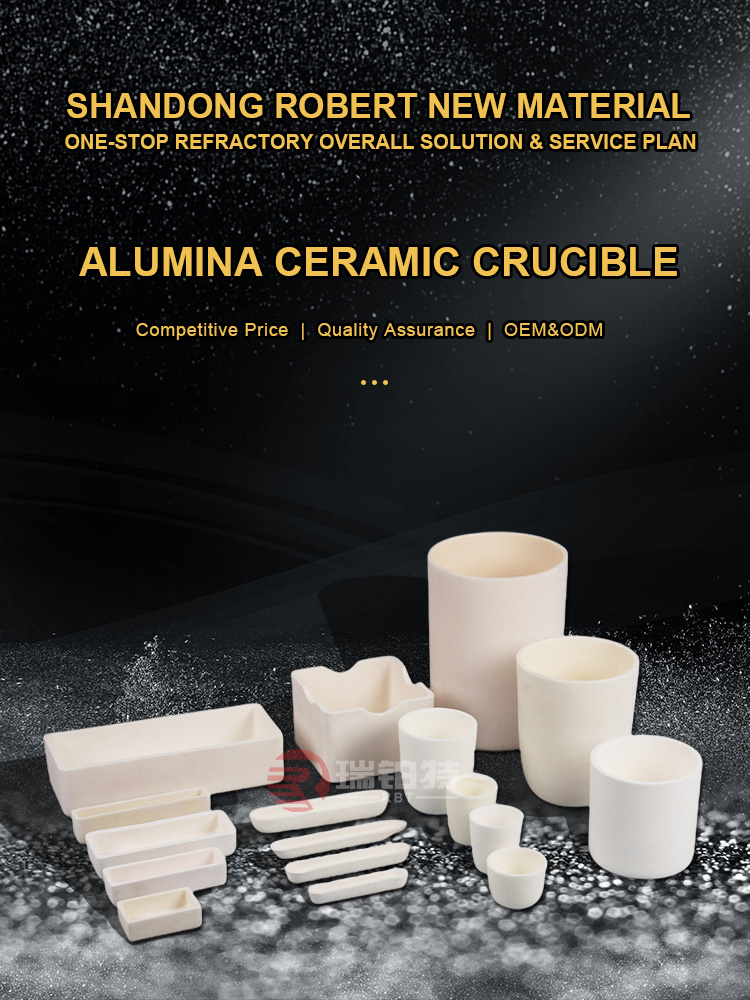

Alumina Ceramic Crucible

Product Information

Alumina ceramic crucible is a high-temperature and corrosion-resistant laboratory container made of high-purity alumina (Al₂O₃) as the main raw material through a specific process. It is widely used in high-temperature experimental environments in the fields of chemistry, metallurgy, and materials science.

Features:

High purity: The purity of alumina in alumina ceramic crucibles is usually as high as 99% or more, ensuring stability and chemical inertness at high temperatures.

High temperature resistance: Its melting point is as high as 2050℃, the long-term use temperature can reach 1650℃, and it can even withstand high temperatures of up to 1800℃ for short-term use.

Corrosion resistance: It has strong resistance to corrosive substances such as acids and alkalis, and can maintain stable performance in various harsh chemical environments.

High thermal conductivity: It can quickly conduct and disperse heat, effectively control the experimental temperature, and improve experimental efficiency.

High mechanical strength: It has high mechanical strength and can withstand large external pressure without being easily damaged.

Low thermal expansion coefficient: Reduces the risk of cracking and damage caused by thermal expansion and contraction.

Easy to clean: The surface is smooth and easy to clean without contaminating the sample, ensuring the accuracy of the experimental results.

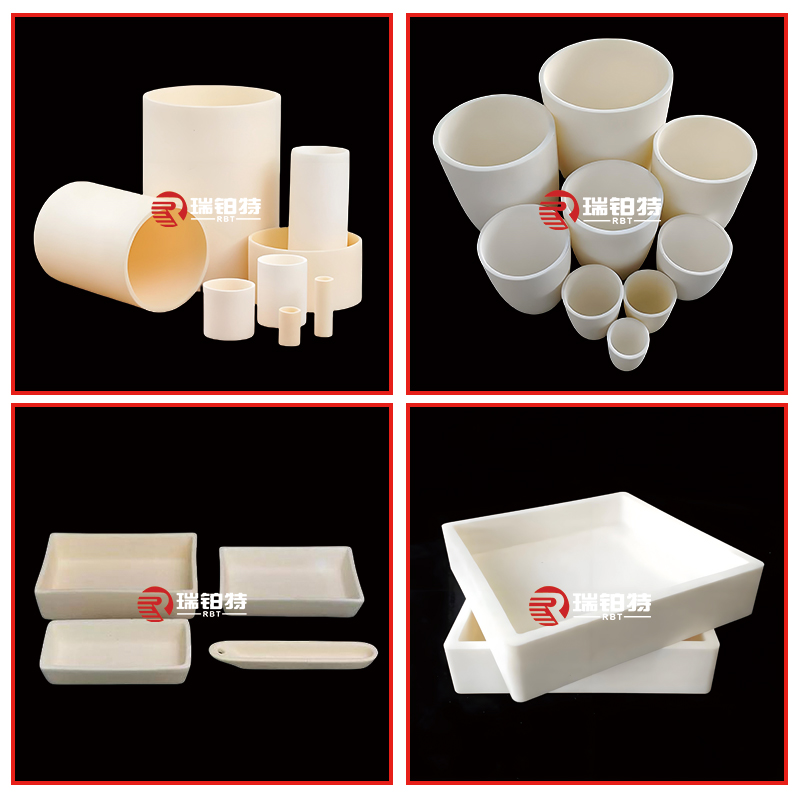

Details Images

|

Purity

|

95%/99%/99.7%/99.9%

|

|

Color

|

White, ivory yellow

|

|

Shape

|

Arc/Square/Rectangle/Cylinder/Boat

|

Product Index

|

Material

|

Alumina

|

||||

|

Properties

|

Units

|

AL997

|

AL995

|

AL99

|

AL95

|

|

Alumina

|

%

|

99.70%

|

99.50%

|

99.00%

|

95%

|

|

Color

|

--

|

lvory

|

lvory

|

lvory

|

lvory&White

|

|

Permeability

|

--

|

Gas-tight

|

Gas-tight

|

Gas-tight

|

Gas-tight

|

|

Density

|

g/cm³

|

3.94

|

3.9

|

3.8

|

3.75

|

|

Straightness

|

--

|

1‰

|

1‰

|

1‰

|

1‰

|

|

Hardness

|

Mohs Scale

|

9

|

9

|

9

|

8.8

|

|

Water Absorption

|

--

|

≤0.2

|

≤0.2

|

≤0.2

|

≤0.2

|

|

Flexural Strength

(Typical 20ºC)

|

Mpa

|

375

|

370

|

340

|

304

|

|

Compressive Strength

(Typical 20ºC)

|

Mpa

|

2300

|

2300

|

2210

|

1910

|

|

Coefficient of Thermal

Expansion

(25ºC to 800ºC)

|

10-6/ºC

|

7.6

|

7.6

|

7.6

|

7.6

|

|

Dielectric Strength

(5mm Thickness)

|

AC-kv/mm

|

10

|

10

|

10

|

10

|

|

Dielectric Loss

25ºC@1MHz

|

--

|

<0.0001

|

<0.0001

|

0.0006

|

0.0004

|

|

Dielectric Constant

|

25ºC@1MHz

|

9.8

|

9.7

|

9.5

|

9.2

|

|

Volume Resistivity

(20ºC) (300ºC)

|

Ω·cm³

|

>1014

2*1012

|

>1014

2*1012

|

>1014

4*1011

|

>1014

2*1011

|

|

Long-term operating

temperature

|

ºC

|

1700

|

1650

|

1600

|

1400

|

|

Thermal Conductivity

(25ºC)

|

W/m·K

|

35

|

35

|

34

|

20

|

Specification

|

Basic Size of Cylindrical Crucible

|

|||

|

Diameter(mm)

|

Height(mm)

|

Wall Thickness

|

Content(ml)

|

|

15

|

50

|

1.5

|

5

|

|

17

|

21

|

1.75

|

3.4

|

|

17

|

37

|

1

|

5.4

|

|

20

|

30

|

2

|

6

|

|

22

|

36

|

1.5

|

10.2

|

|

26

|

82

|

3

|

34

|

|

30

|

30

|

2

|

15

|

|

35

|

35

|

2

|

25

|

|

40

|

40

|

2.5

|

35

|

|

50

|

50

|

2.5

|

75

|

|

60

|

60

|

3

|

130

|

|

65

|

65

|

3

|

170

|

|

70

|

70

|

3

|

215

|

|

80

|

80

|

3

|

330

|

|

85

|

85

|

3

|

400

|

|

90

|

90

|

3

|

480

|

|

100

|

100

|

3.5

|

650

|

|

110

|

110

|

3.5

|

880

|

|

120

|

120

|

4

|

1140

|

|

130

|

130

|

4

|

1450

|

|

140

|

140

|

4

|

1850

|

|

150

|

150

|

4.5

|

2250

|

|

160

|

160

|

4.5

|

2250

|

|

170

|

170

|

4.5

|

3350

|

|

180

|

180

|

4.5

|

4000

|

|

200

|

200

|

5

|

5500

|

|

220

|

220

|

5

|

7400

|

|

240

|

240

|

5

|

9700

|

|

Basic Size of Rectangled Crucible |

|||||

|

Length(mm) |

Width(mm) |

Height(mm) |

Length(mm) |

Width(mm) |

Height(mm) |

|

30 |

20 |

16 |

100 |

60 |

30 |

|

50 |

20 |

20 |

100 |

100 |

30 |

|

50 |

40 |

20 |

100 |

100 |

50 |

|

60 |

30 |

15 |

110 |

80 |

40 |

|

75 |

52 |

50 |

110 |

110 |

35 |

|

75 |

75 |

15 |

110 |

80 |

40 |

|

75 |

75 |

30 |

120 |

75 |

40 |

|

75 |

75 |

45 |

120 |

120 |

30 |

|

80 |

80 |

40 |

120 |

120 |

50 |

|

85 |

65 |

30 |

140 |

140 |

40 |

|

90 |

60 |

35 |

150 |

150 |

50 |

|

100 |

20 |

15 |

200 |

100 |

25 |

|

100 |

20 |

20 |

200 |

100 |

50 |

|

100 |

30 |

25 |

200 |

150 |

5 |

|

100 |

40 |

20 |

|||

|

Basic Size of Arc Crucible

|

||||

|

Top Dia.(mm)

|

Base Dia.(mm)

|

Height(mm)

|

Wall Thickness(mm)

|

Content(ml)

|

|

25

|

18

|

22

|

1.3

|

5

|

|

28

|

20

|

27

|

1.5

|

10

|

|

32

|

21

|

35

|

1.5

|

15

|

|

35

|

18

|

35

|

1.7

|

20

|

|

36

|

22

|

42

|

2

|

25

|

|

39

|

24

|

49

|

2

|

30

|

|

52

|

32

|

50

|

2.5

|

50

|

|

61

|

36

|

54

|

2.5

|

100

|

|

68

|

42

|

80

|

2.5

|

150

|

|

83

|

48

|

86

|

2.5

|

200

|

|

83

|

52

|

106

|

2.5

|

300

|

|

86

|

49

|

135

|

2.5

|

400

|

|

100

|

60

|

118

|

3

|

500

|

|

88

|

54

|

145

|

3

|

600

|

|

112

|

70

|

132

|

3

|

750

|

|

120

|

75

|

143

|

3.5

|

1000

|

|

140

|

90

|

170

|

4

|

1500

|

|

150

|

93

|

200

|

4

|

2000

|

Applications

1. High-temperature heat treatment: Alumina ceramic crucibles can withstand long-term use in high-temperature environments and have good heat resistance. Therefore, they are widely used in high-temperature heat treatment fields, such as sintering, heat treatment, melting, annealing and other processes.

2. Chemical analysis: Alumina ceramic crucibles have good corrosion resistance and can be used for the analysis and reaction of various chemical reagents, such as acid and alkali solutions, redox reagents, organic reagents, etc.

3. Metal smelting: The high-temperature heat resistance and good chemical stability of alumina ceramic crucibles make them useful in metal smelting and casting processes, such as smelting and casting of aluminum, steel, copper and other metals.

4. Powder metallurgy: Alumina ceramic crucibles can be used to prepare various metal and non-metal powder metallurgy materials, such as tungsten, molybdenum, iron, copper, aluminum, etc.

5. Thermocouple manufacturing: Alumina ceramic crucibles can be used to manufacture thermocouple ceramic protection tubes and insulating cores and other components to ensure the stability and accuracy of thermocouples.

Laboratory and industrial analysis

Metal smelting

Powder metallurgy

Thermocouple manufacturing

Package&Warehouse

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.