Calcined Bauxite

Product Information

Calcined bauxite is one of the principal ore of aluminum. Rotary kiln calcined bauxite is obtained by calcining superior grade bauxite at high temperature (from 850ºC to 1600ºC) in the rotary kiln. This removes moisture thereby increasing the alumina content.

Calcined bauxite is roughly divided into special-grade bauxite, first-grade bauxite, second-grade bauxite, and third-grade bauxite according to the content of impurities such as Al2O3, Fe2O3, and SiO2, as well as the bulk density of clinker and water absorption. In order to make customers' purchase more intuitive, our factory uses the Al2o3 content of bauxite as a label to subdivide it into 55, 65, 70, 75, 80, 85, 88 and 90.

Besides, through calcination, the density and refractory resistance will also be improved to varying degrees. The grade of bauxite can be increased greatly.

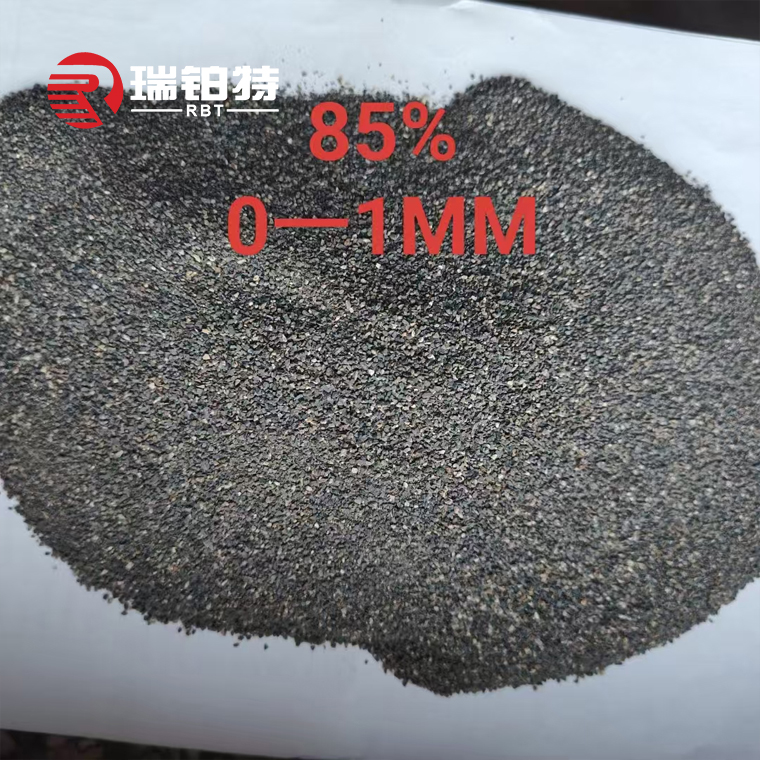

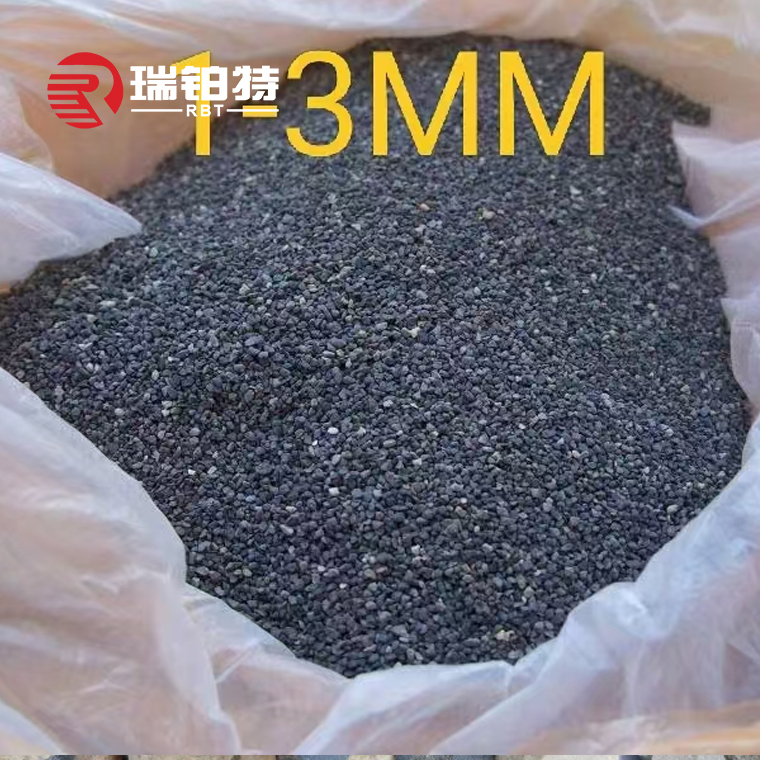

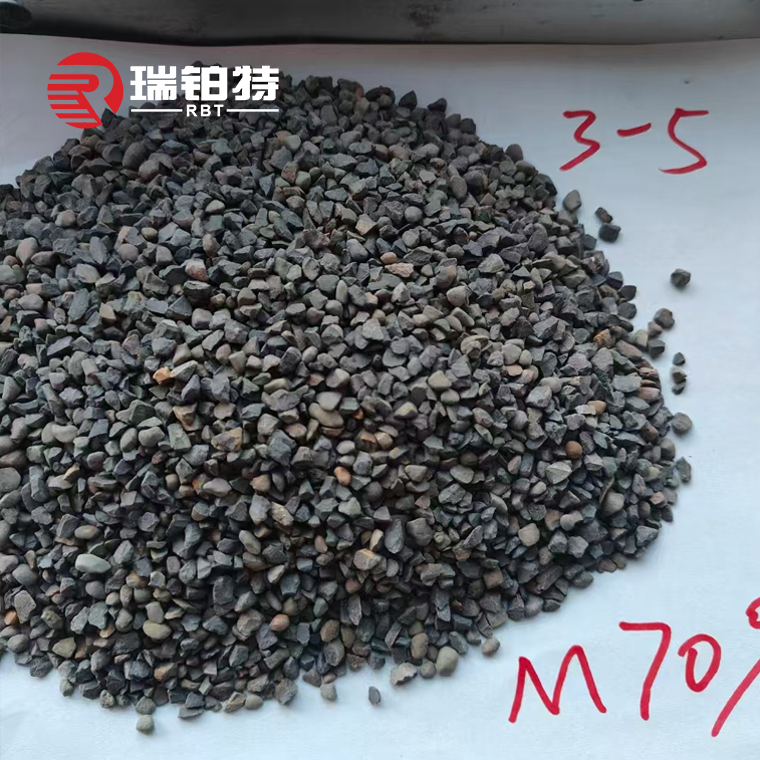

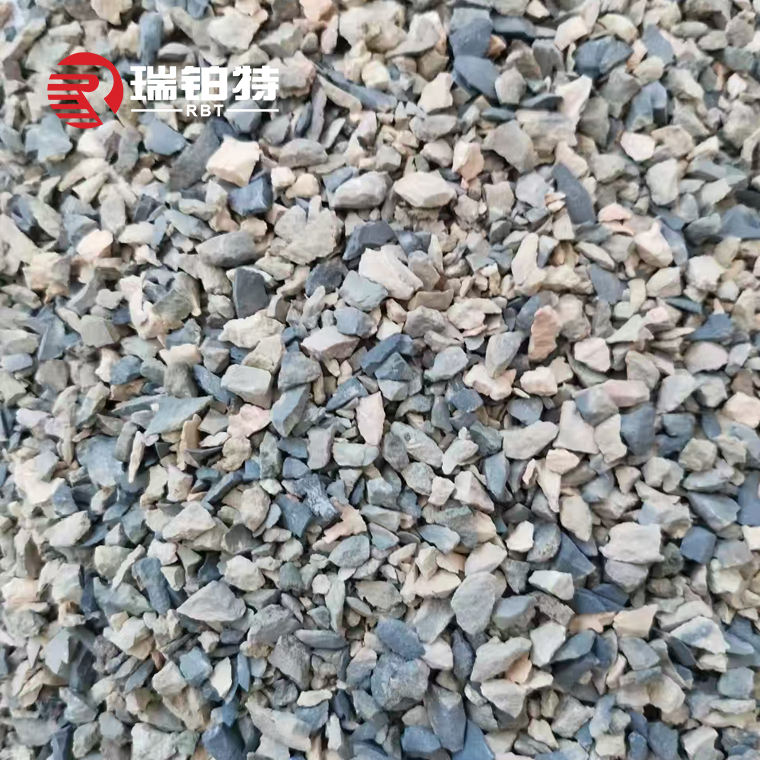

The calcined bauxite can be processed into bauxite sand and bauxite powder of different particle sizes, both of which can be directly used as refractory sand. It has a very high status in the field of refractory materials.

Details Images

Product Index

|

Al2O3

|

Fe2O3

|

TiO2

|

K2O+Na2O

|

CaO+MgO

|

Bulk Density

|

|

90min

|

≤1.8

|

≤4.0

|

≤0.25

|

≤0.5

|

≥3.30

|

|

88min

|

≤1.8

|

≤4.0

|

≤0.25

|

≤0.5

|

≥3.25

|

|

87min

|

≤2

|

≤4.0

|

≤0.3

|

≤0.5

|

≥3.20

|

|

86min

|

≤2

|

≤4.0

|

≤0.3

|

≤0.5

|

≥3.10

|

|

85min

|

≤2

|

≤4.0

|

≤0.3

|

≤0.5

|

≥3.00

|

|

80min

|

≤3.0

|

≤4.0

|

≤0.3

|

≤0.5

|

≥2.80

|

|

75min

|

≤3.0

|

≤4.0

|

≤0.3

|

≤0.5

|

≥2.70

|

|

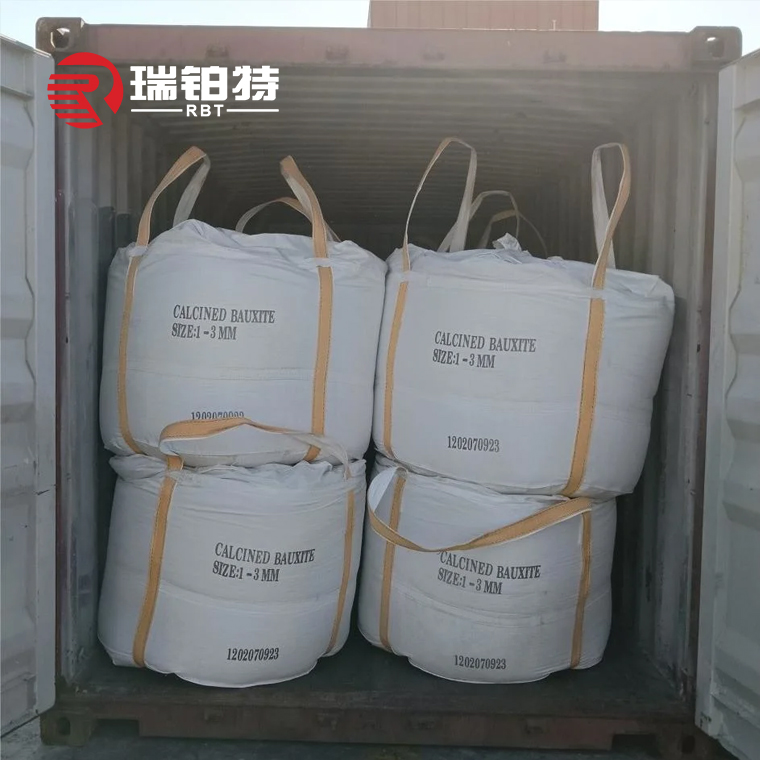

Size

|

200mesh, 0-1mm, 1-3mm, 3-5mm, 5-8mm..., or according to customers` request

|

||||

Application

1. Manufacturing high-quality refractory materials: Calcined bauxite is often used to manufacture various refractory bricks, refractory castables, etc. due to its high temperature stability and chemical stability. These refractory materials are widely used in high-temperature industrial fields such as steel, non-ferrous metallurgy, glass, cement, etc., and are used to construct key parts such as furnace walls, furnace tops, and furnace bottoms to ensure production safety and product quality in high temperature environments.

2. Precision casting: Calcined bauxite clinker can be processed into fine powder for manufacturing

casting molds, which is suitable for precision casting in military, aerospace, communications, instrumentation, machinery, and medical equipment departments. Its high precision and high temperature stability ensure the quality and performance of casting products.

3. Manufacturing aluminum silicate refractory fiber: After high-aluminum clinker is melted at high temperature, sprayed with high-pressure and high-speed air or steam, and cooled, it can be made into aluminum silicate refractory fiber. This fiber has the advantages of light weight, high temperature resistance, good thermal stability, and low thermal conductivity. It can be used in a variety of industrial fields such as steel, non-ferrous metallurgy, electronics, petroleum, chemical industry,

and aerospace.

4. Catalyst carrier: In the chemical industry, calcined bauxite can be used to make catalyst carriers, improve the activity and stability of catalysts, and extend the service life of catalysts.

5. Cement production: Calcined bauxite is added to cement as an additive, which can significantly improve the strength and durability of cement, while improving the fluidity and anti-permeability of cement and reducing production costs.

6. Ceramic production: Calcined bauxite is an indispensable raw material in ceramic production. After high-temperature treatment, it significantly improves the refractoriness, mechanical strength and crack resistance of ceramics, giving ceramics a unique decorative effect.

7. Ceramic Proppant: In oil and gas drilling, calcined bauxite 200 mesh can be used as ceramic proppant to improve drilling efficiency.

Aluminum Silicate Refractory Fiber

Ceramic Industry

Manufacturing Refractory Materials

Precision Casting

Cement Production

Precision Casting

Package&Warehouse

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.