Calcium Silicate Insulation Boards

Product Description

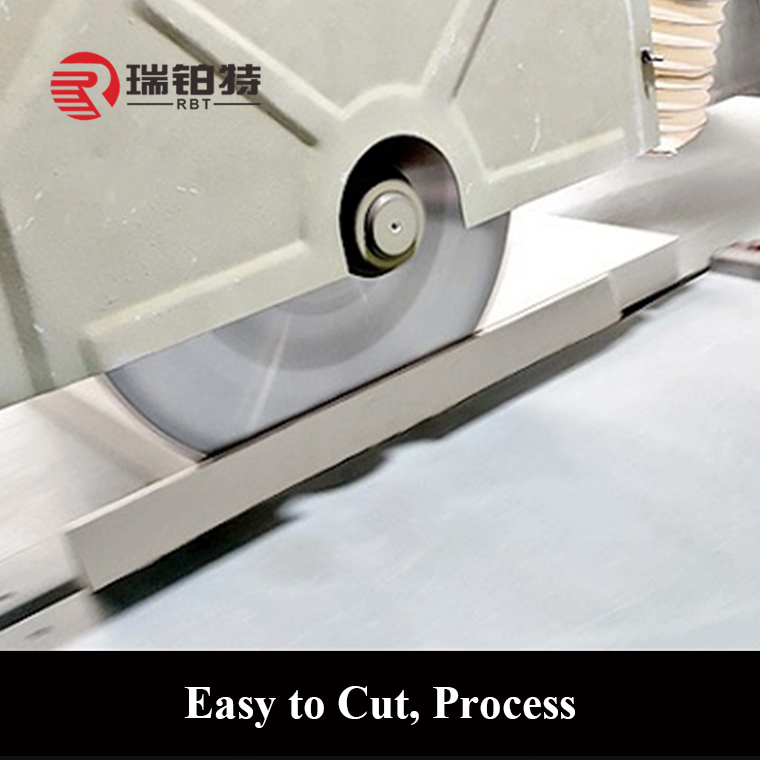

Calcium silicate board for thermal insulation is called microporous calcium silicate. It is a new type of white, hard thermal insulation material with the characteristics of light bulk density, high strength, low thermal conductivity, high temperature resistance, corrosion resistance, cutting and sawing. It is widely used in the thermal insulation and fireproof and sound insulation of equipment pipelines, walls and roofs in the fields of electricity, metallurgy, petrochemicals, construction, and ships. The thickness is usually above 30mm and the density is 200-1000kg/m3.

Calcium silicate pipe is a new type of thermal insulation material made of silicon oxide (quartz sand, powder, silicon, algae, etc.), calcium oxide (also useful lime, carbide slag, etc.) and reinforcing fiber (such as mineral wool, glass fiber, etc.) as the main raw materials, through stirring, heating, gelling, molding, autoclaving hardening, drying and other processes. Its main materials are highly active diatomaceous earth and lime. Under high temperature and high pressure, hydrothermal reaction occurs to boil the product, and mineral wool or other fibers as reinforcing agents are added to regenerate it, and coagulation aid materials are added to form a new type of thermal insulation material.

Features

A. Low thermal conductivity and good thermal insulation.

B. Good thermal stability and small shrinkage value when the temperature changes.

C. Low density, small bulk density, less heat storage.

D. Its specific strength is the highest among the hard insulation materials.

E. It has good durability and has no similar pulverization of ceramic fiber felt after long-term use.

F. No carcinogens - asbestos, sulfur, chlorine and other toxic substances and other low melting point organic binders.

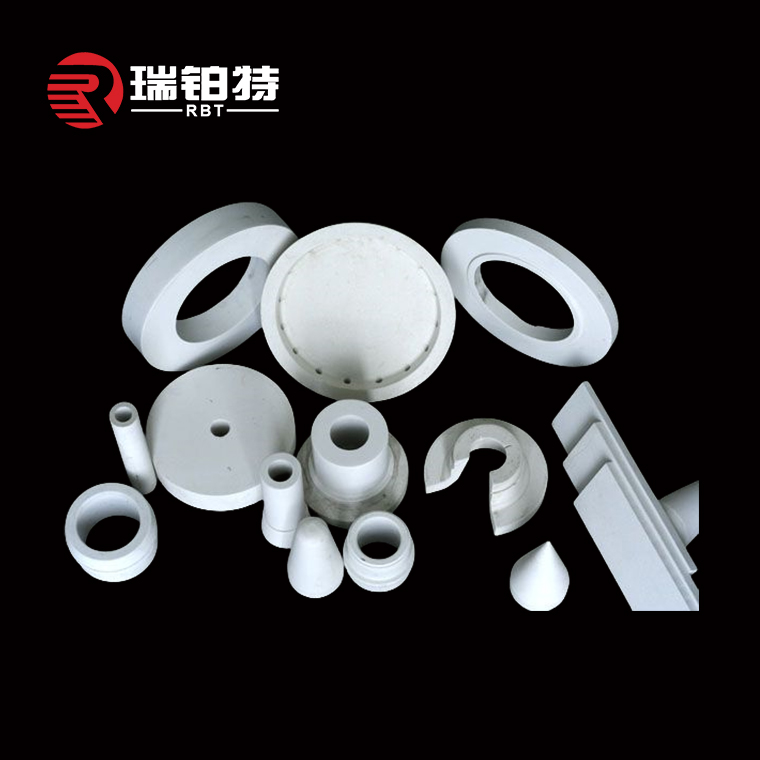

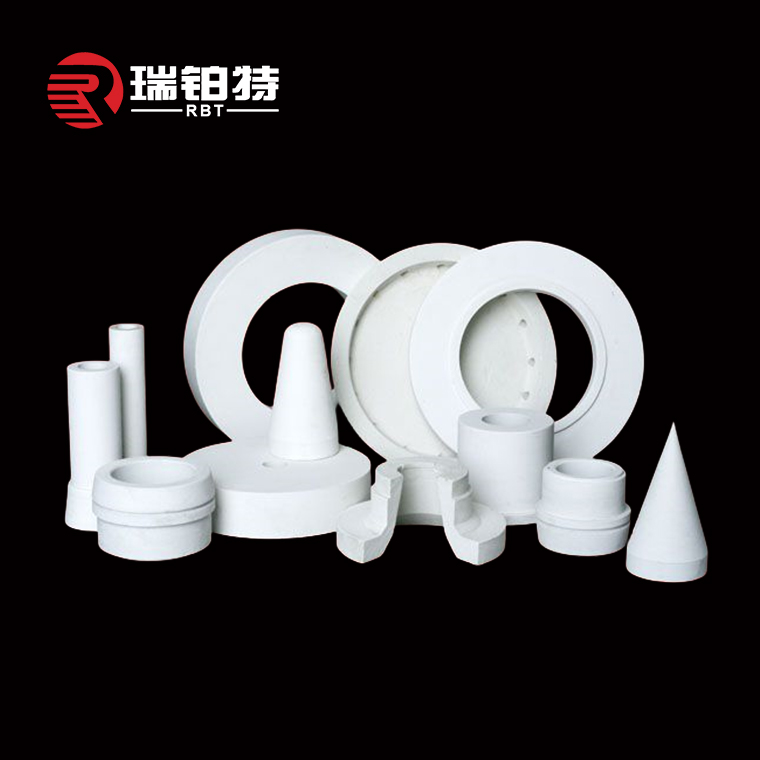

Details Images

|

Classification

|

STD/HTC/EHD

|

|

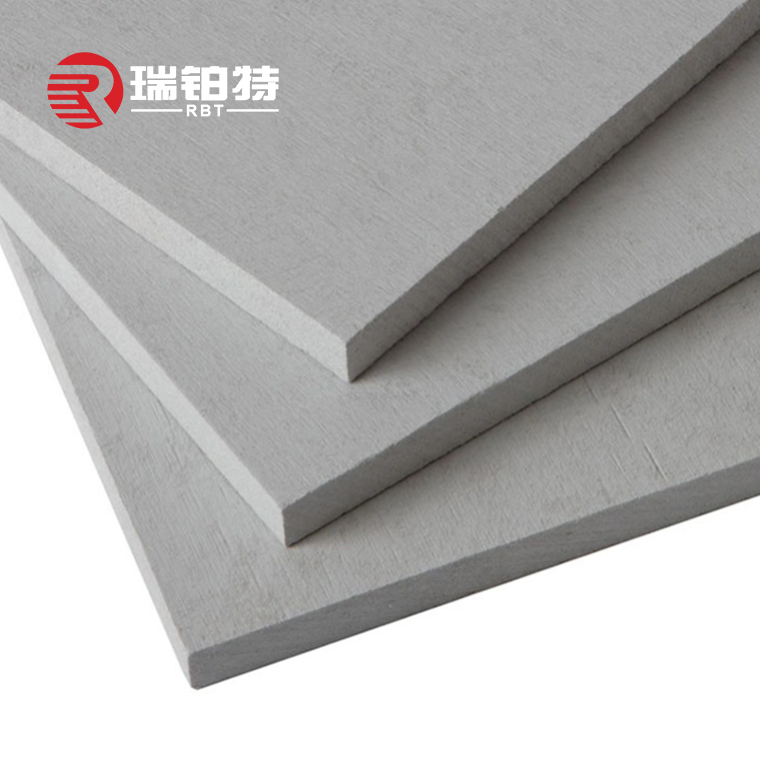

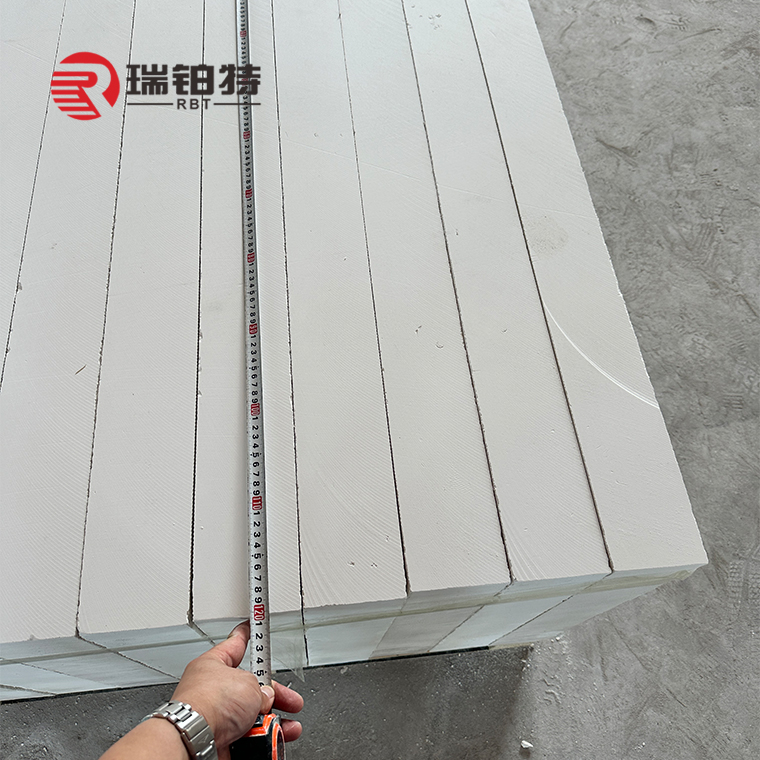

Calcium Silicate Board Regular Size(mm)

|

1000*500*50 1200*600*50 900*600*50

|

|

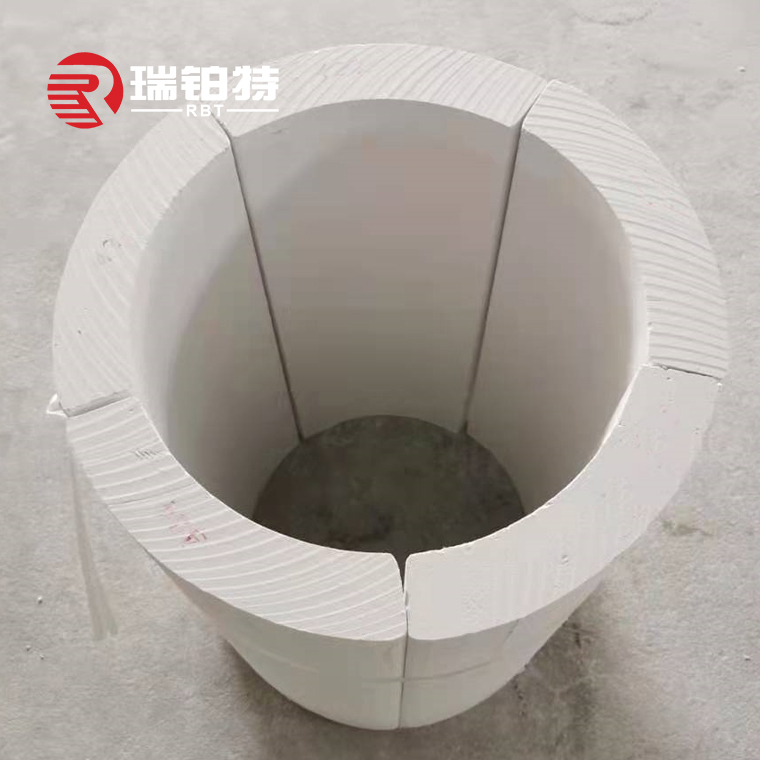

Calcium Silicate Pipe Thickness(mm)

|

20-100

|

Calcium silicate board

Calcium silicate board

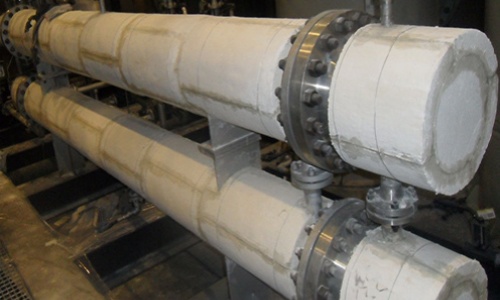

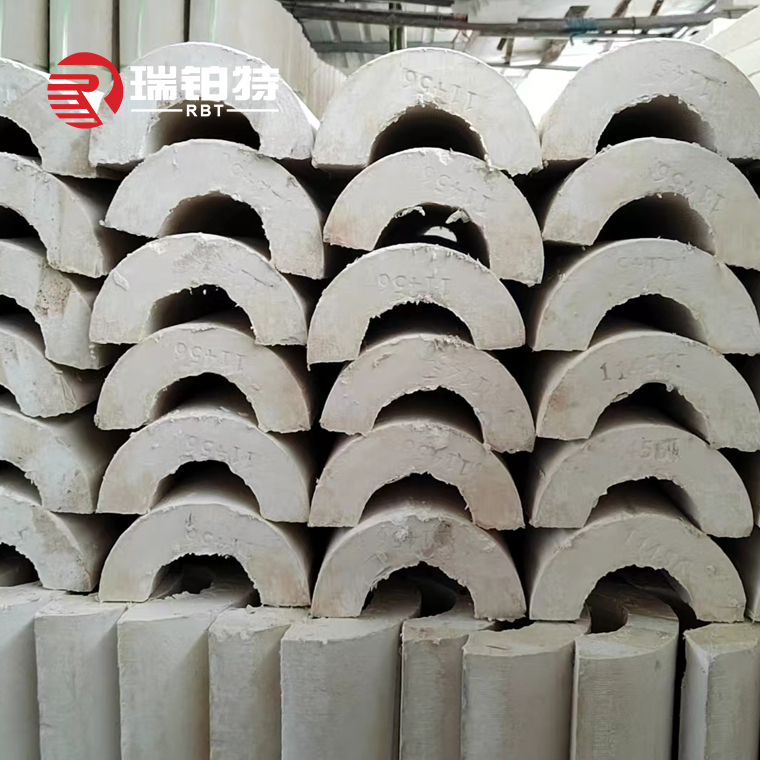

Calcium Silicate Pipe

Calcium Silicate Pipe

Shaped Parts

Shaped Parts

Easy to Cut, Process

Support Customization

Product Index

|

INDEX

|

STD

|

HTC

|

EHD

|

|

Max Service Temperature(℃)

|

1000

|

1100

|

1100

|

|

Modulus of Rupture(MPa) ≤

|

0.45

|

0.5

|

6.5

|

|

Bulk Density(kg/m3)

|

230

|

250

|

950

|

|

Thermal Conductivity(W/m.k)

|

100℃/0.064

|

100℃/0.065

|

100℃/0.113

|

|

Combustion Performance

|

A1

|

||

|

Al2O3(%) ≥

|

0.4~0.5%

|

||

|

Fe2O3(%) ≤

|

0.3~0.4%

|

||

|

SiO2(%) ≤

|

48~52%

|

||

|

CaO(%) ≥

|

35~40%

|

||

Application

Silicon calcium board can be made into board, block or casing shape, used as electric power, chemical industry, metallurgy, shipbuilding and other heat pipe and industrial furnace insulation material, also can be used as buildings, instruments and equipment fireproofing insulation.

1. Metallurgical industry: heating furnace, soaking furnace, annealing furnace, high temperature flue, hot air duct.

2. Petrochemical industry: heating furnace, ethylene cracking furnace, hydrogenation furnace, catalytic cracking furnace.

3. Cement industry: rotary kiln, calciner kiln, preheater, air duct, kiln cover, cooler.

4. Ceramic industry: Tunnel kilns and core panels for tunnel kilns.

5. Glass industry: furnace bottom and walls.

6. Electric power industry: preheating furnace tubes.

7. Non-ferrous metal industry: electrolyzers.

Calcium silicate pipes are widely used in the thermal insulation, fire and sound insulation of equipment pipes, walls and roofs in the electric power, metallurgy, petrochemical, cement manufacturing, construction, shipbuilding and other industries.

Metallurgical Industry

Cement Industry

Petrochemical Industry

Ceramic Industry

Our Factory

Package&Warehouse

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.