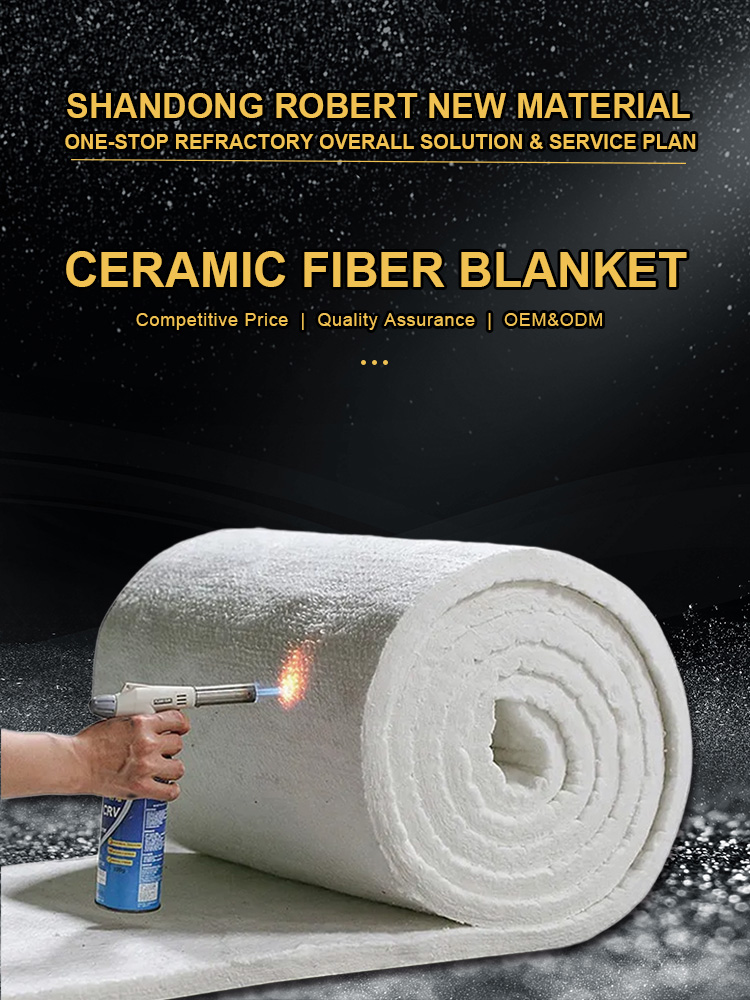

Ceramic Fiber Blankets

Product Information

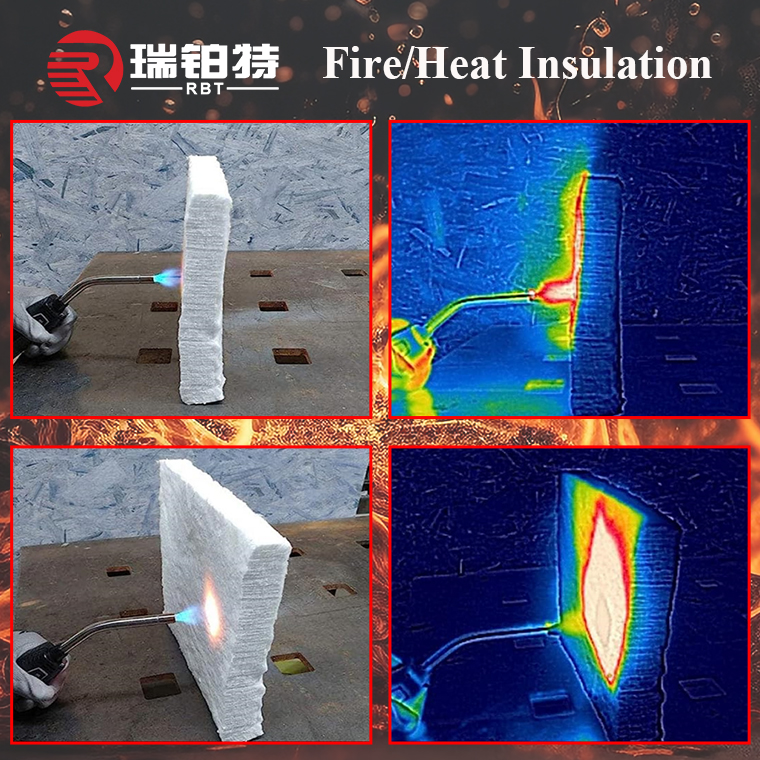

Ceramic fiber blanket is manufactured by refractory ceramic fibers, providing effective solutions to a wide range of thermal management problems.

Utilizing our proprietary high output blowing and spinning techniques, these products supply superior insulating performance, flexibility and resilience.

Features

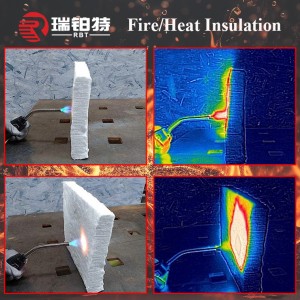

1. High temperature resistance, the highest operating temperature can reach 1350℃.

2. Low thermal conductivity, good thermal insulation performance. Under the same conditions, the thermal conductivity of aluminum silicate products is more than 30% lower than that of other insulation materials.

3. Light weight and good stability, with the characteristics of softness, lightness and elasticity.

4. Not wetted by molten metal. Has good chemical stability.

5. Good sound absorption and sound insulation performance, with good sound insulation effect.

6. Good electrical insulation, with a high dielectric constant; can be used as high-frequency insulation material.

Details Images

|

Regular Size(mm)

|

14400*610*12.5 3600*610*50 7200*610*25

|

|

Model

|

COM/STD/HC/HA/HZ/HAZ

|

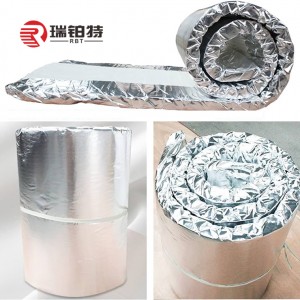

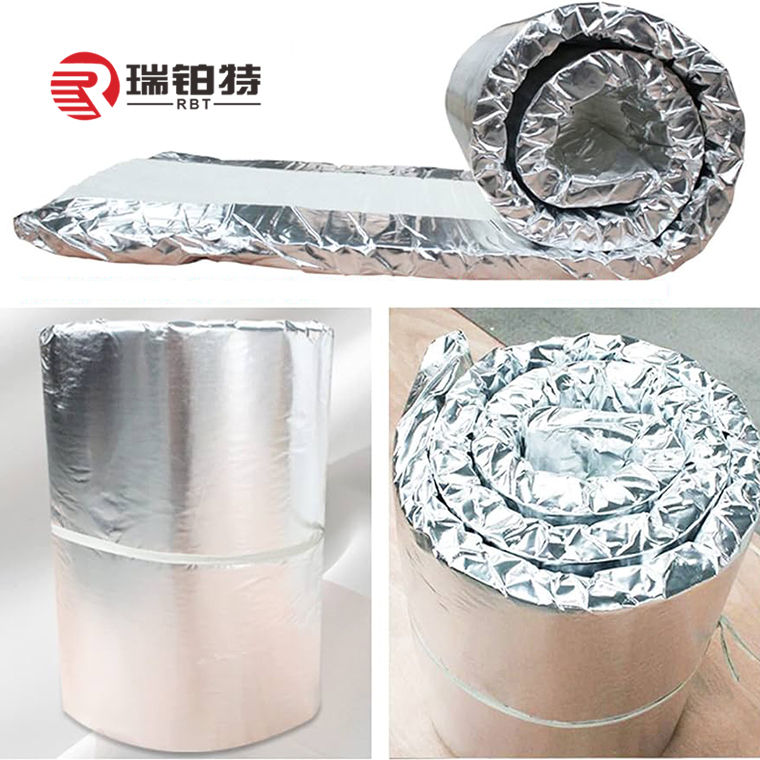

Details ImagesAluminum Foil Faced Ceramic Fiber Blanket

1. Fireproof Insulation: High-quality ceramic fiber insulation blanket backed with strong 50-micron thick Aluminum Foil is a high heat resistant non-combustible blanket, rated up to 1350℃ (on the side of the ceramic wool of blanket, not on the side of the aluminum foil attached)

2. Strong and Durable: This non-combustible blanket has high tensile strength and thermal shock resistance which allows it to maintain its soft structure without shrinkage when used within the recommended range of temperature.

3. Lightweight & Flexible: Being lightweight and flexible these blankets are extremely easy to install & work with. Moreover, they are easy to cut in the desired shape as well according to the need, making their installation effortless and hassle-free.

4. Enhanced Protection: These strong and durable ceramic fiber blankets with aluminum foil attached on one side are meant to provide surface protection to the blanket from external damage. Thus providing superior insulation value and protection to your parts/components or surface.

Product Index

|

INDEX

|

COM

|

STD

|

HC

|

HA

|

HZ

|

HAZ

|

|

Classification Temperature(℃)

|

1050

|

1260

|

1260

|

1360

|

1430

|

1400

|

|

Working Temperature(℃) ≤

|

900 |

1050

|

1100

|

1200

|

1350

|

1200

|

|

Slag Content(%) ≤

|

20

|

15

|

15

|

15

|

12

|

12

|

|

Bulk Density(kg/m3)

|

96~160

|

|||||

|

Thermal Conductivity(W/m.k)

|

0.086

(400℃)

0.120

(800℃)

|

0.086

(400℃)

0.120

(800℃)

|

0.086

(400℃)

0.110

(800℃)

|

0.092

(400℃)

0.186

(1000℃)

|

0.092

(400℃)

0.186

(1000℃)

|

0.98

(400℃)

0.20

(1000℃)

|

|

Permanent Linear Change×24h(%)

|

-4/1000℃

|

-3/1000℃

|

-3/1100℃

|

-3/1200℃

|

-3/1350℃

|

-3/1400℃

|

|

Modulus of Rupture(MPa)

|

0.08~0.12

|

|||||

|

Al2O3(%) ≥

|

44

|

45

|

45

|

50

|

39

|

39

|

|

Fe2O3(%) ≤

|

1.0

|

1.0

|

0.2

|

0.2

|

0.2

|

0.2

|

|

Al2O3+SiO2(%) ≥

|

98

|

99

|

99

|

99

|

84

|

90

|

|

ZrO2(%)

|

|

|

|

|

13-15

|

5~7

|

|

Regular Size(mm)

|

14400*610*12.5 3600*610*50 7200*610*25

|

|||||

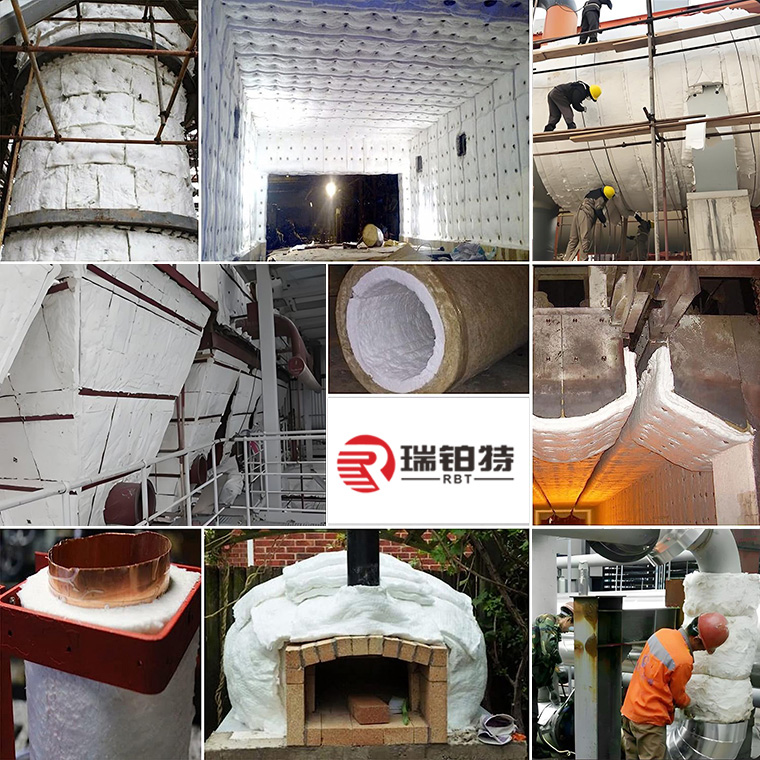

Application

Ceramic Fiber Blankets

1. Lining, insulation and repair for furnaces, kilns, ovens, boilers;

2. Insulation for power plant, turbine, thermal reactor, generator and nuclear applications;

3. Expansion joint seal and insulation;

4. Wrapping and insulation for high temperature pipes or metal casting;

5. Fire protective insulation and lining other high temperature seal, gasket, insulation or protection.

Aluminum Foil Faced Ceramic Fiber Blanket

Heat shield blankets are designed for passive fire protection applications and use in high-temperature systems. It has an extensive range of applications for fire protection and insulation purpose. It can be applied for kiln, forge, furnace, boiler, foundry, chimney, fireplace, and pipe insulation. It is also widely used as insulation in HVAC setups. Besides this, it can also be used during scorching, burning, and charring while soldering, brazing, welding, grinding, or cutting.

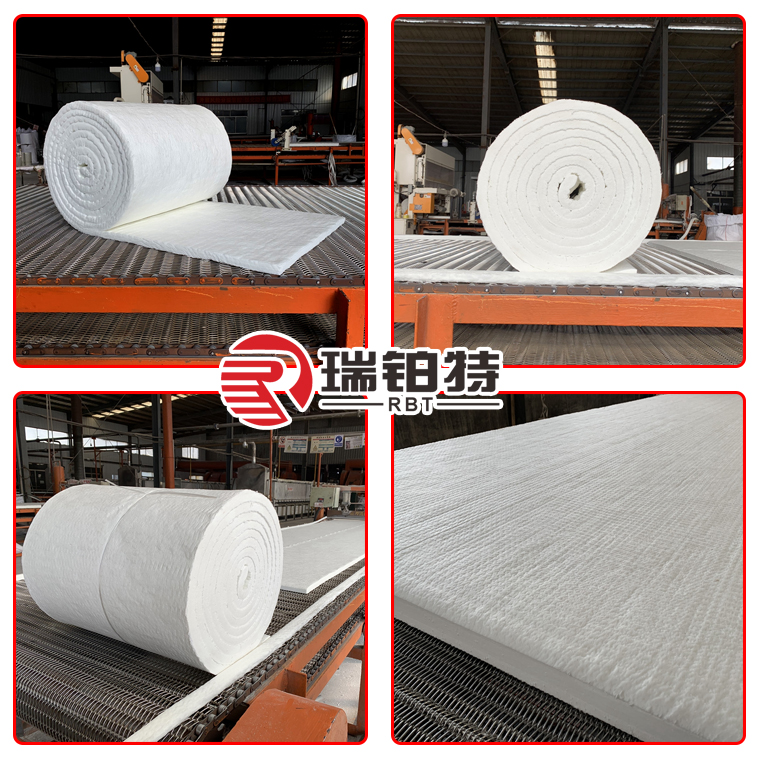

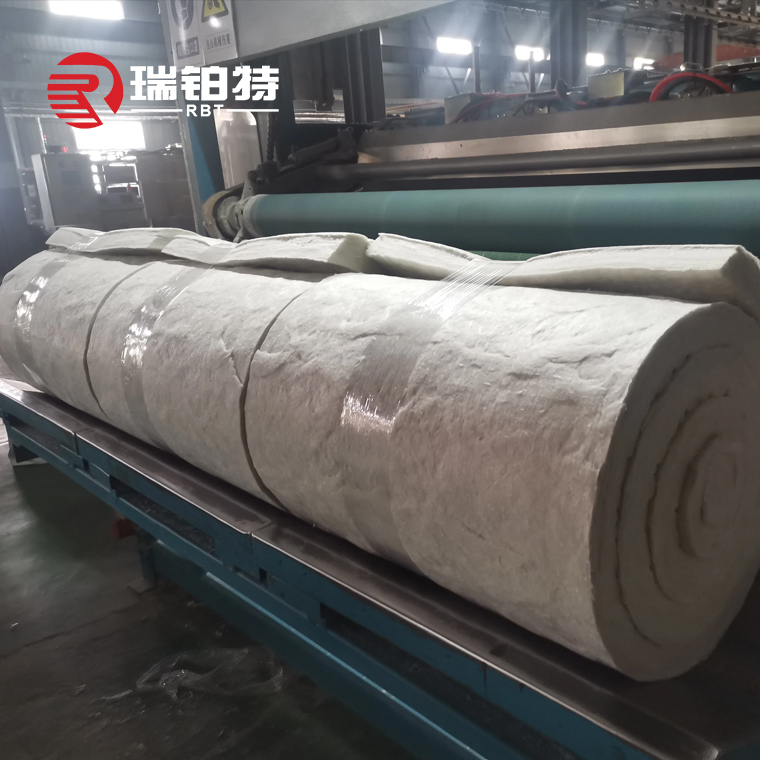

Production Workshop

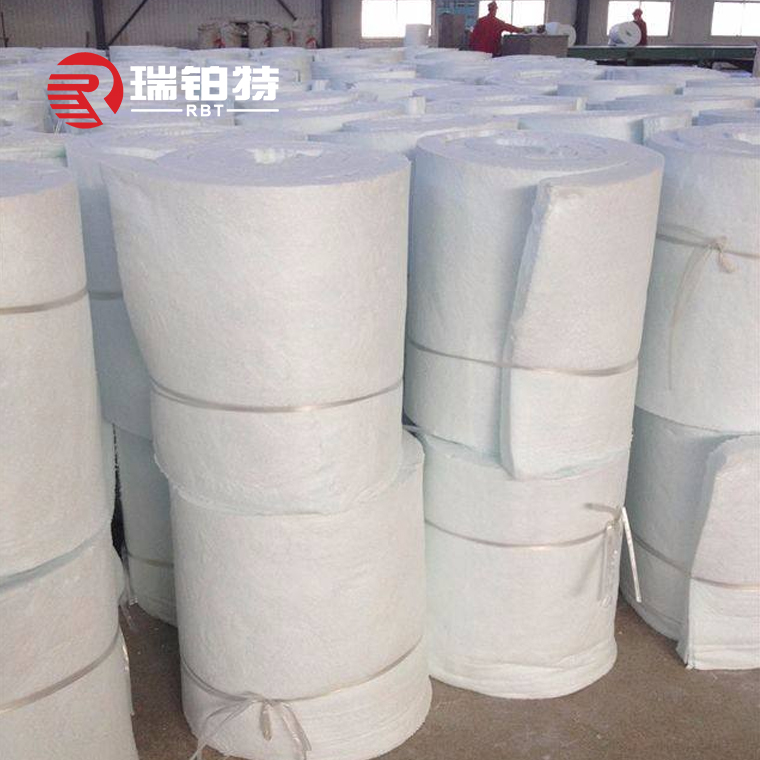

Package&Warehouse

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.