China Manufacturer for Used Fused Zirconium Corundum Refractory Brick for Glass Furnace

Our target is always to satisfy our customers by offering golden support, superior value and high quality for China Manufacturer for Used Fused Zirconium Corundum Refractory Brick for Glass Furnace, To deliver clients with great equipment and companies, and frequently develop new machine is our company’s business objectives. We look ahead for your cooperation.

Our target is always to satisfy our customers by offering golden support, superior value and high quality for China Fused Refractory Blocks and Azs Block, Our company considers that selling is not only to gain profit but also popularize the culture of our company to the world. So we have been working hard to give you the wholehearted service and willing to provide you the most competitive price in the market

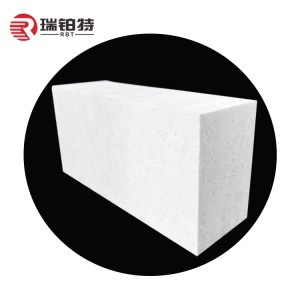

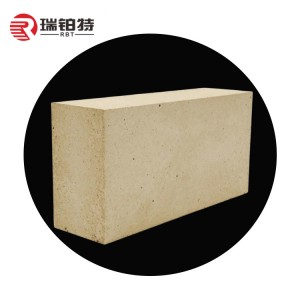

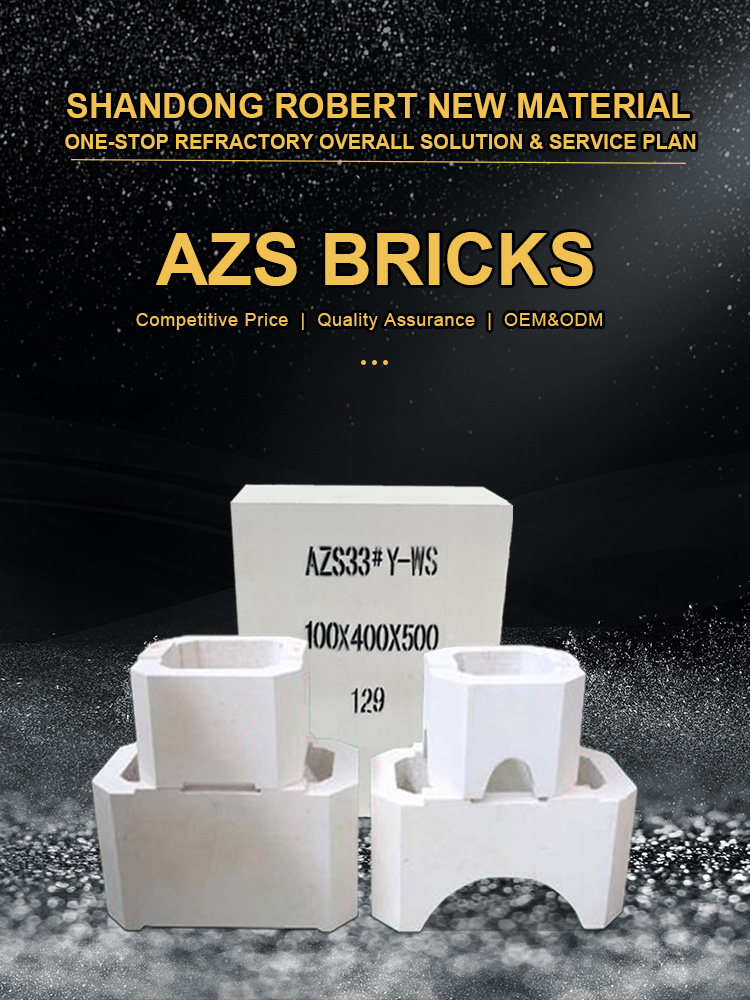

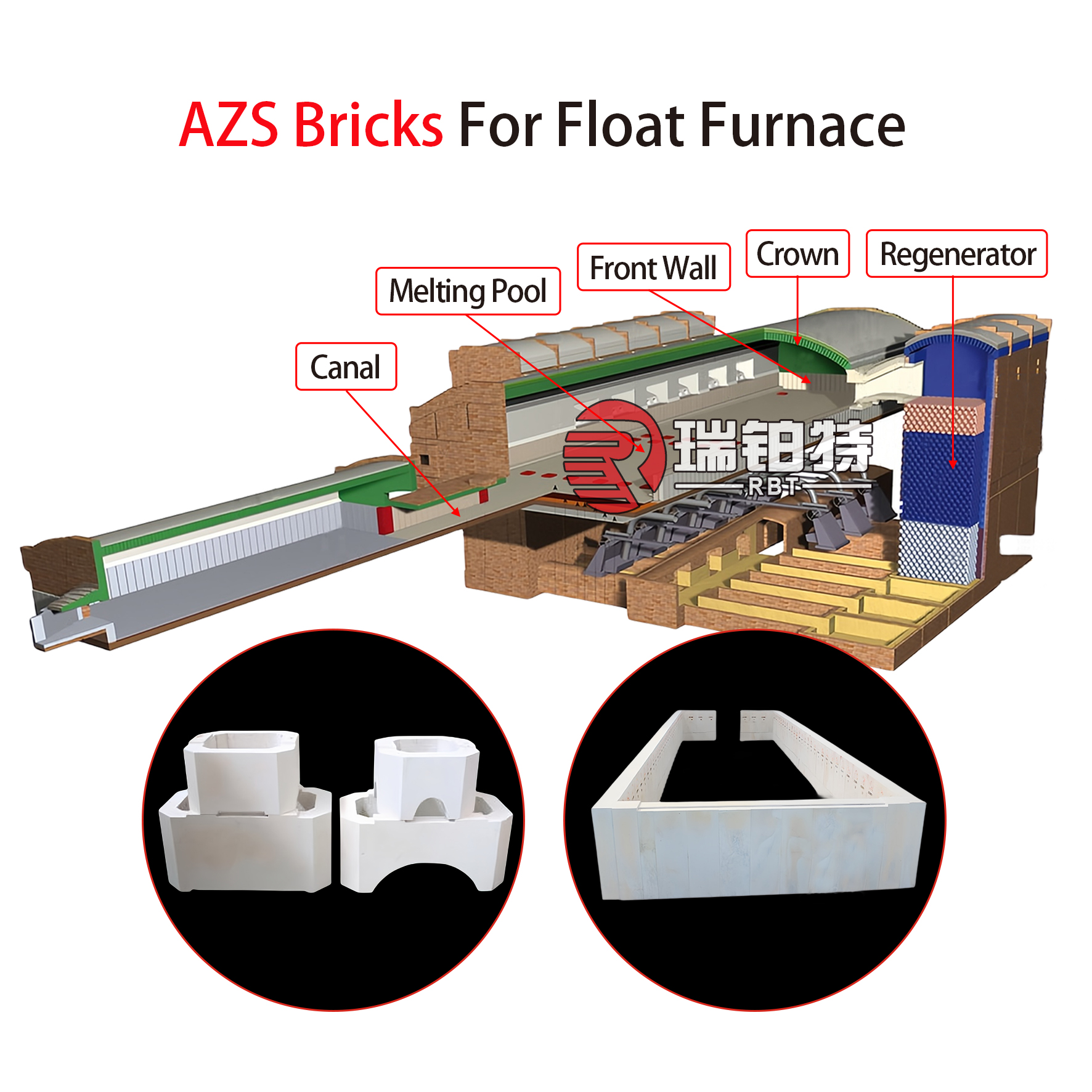

Product Information

AZS block is also called fused zirconia corundum brick which contains Al2O3-ZrO2-SiO2. The fused cast AZS block is made of pure alumina powder and zircon sand (consisting of 65% zirconia and 34% SiO2). After the alumina powder and zircon sand are melted in an electric furnace, they are cast into various molds and cooled down to become white solids.

Model: AZS-33/AZS-36/AZS-41

Features

1. High refractoriness

2. Good thermal shock resistance

3. Good creep-resisting property

4. Good chemical stability

5. Good high temperature strength and volume stability

6. High erosion resistance

Details Images

Casting Method

| Model | AZS-33 | ||

| Casting Method | Description | Density(g/cm3) | Application |

|

Ordinary Casting (PT) |

It is a common casting method, and the shrinkage cavity of the product is located at the lower part of the casting port | ≥3.40 | Small stove top; melting pool; feed port feeder; non-glass contact area |

| Tilt Casting(QX) | The inclined casting method is adopted, and the shrinkage cavity of the product is biased at the lower end, which is mainly used as pool wall brick. | ≥3.40 | Melting pool wall |

| No Shrinkage Cavity Casting(WS) | Shrinkage-free product with the shrinkage cavity portion removed from the cast brick | ≥3.70 | Side wall, kiln ridge, pavement, special-shaped brick |

| Quasi Shrinkage Free Casting(ZWS) | Similar to non-shrinkage casting, the shrinkage cavity of the cast brick is basically removed. | ≥3.60 | Melting pool wall |

| Model | AZS-36 | ||

| Casting Method | Description | Density(g/cm3) | Application |

|

Ordinary Casting (PT) |

It is a common casting method, and the shrinkage cavity of the product is located at the lower part of the casting port | ≥3.50 | Small stove top; melting pool; feed port feeder; non-glass contact area |

| Tilt Casting(QX) | The inclined casting method is adopted, and the shrinkage cavity of the product is biased at the lower end, which is mainly used as pool wall brick. | ≥3.50 | Melting pool wall |

| No Shrinkage Cavity Casting(WS) | The shrinkage cavity part of the cast brick is completely removed. | ≥3.80 | Melting pool wall, bottom plate, special-shaped brick |

| Quasi Shrinkage Free Casting(ZWS) | Similar to non-shrinkage casting, the shrinkage cavity of the cast brick is basically removed. | ≥3.70 | Melting pool wall |

| Model | AZS-41 | ||

| Casting Method | Description | Density(g/cm3) | Application |

|

No Shrinkage Cavity Casting(WS) |

Similar to quasi-shrinkless, the shrinkage cavity of the cast brick is completely removed. | ≥3.90 | Melting pool wall; liquid flow hole; corner of feeding port; bubbling brick; kiln chopping; electrode hole brick; special-shaped brick |

|

Quasi Shrinkage Free Casting(ZWS) |

Basically cut off the shrinkage cavity of the cast brick | ≥3.85 | Melting pool wall |

Product Index

| Item | AZS33 | AZS36 | AZS41 | |

| Chemical Composition(%) | Al2O3 | ≥50.00 | ≥49.00 | ≥45.00 |

| ZrO2 | ≥32.50 | ≥35.50 | ≥40.50 | |

| SiO2 | ≤15.00 | ≤13.50 | ≤12.50 | |

| Na2O+K2O | ≤1.30 | ≤1.35 | ≤1.30 | |

| Bulk Density(g/cm3) | ≥3.75 | ≥3.85 | ≥4 | |

| Apparent Porosity(%) | ≤1.2 | ≤1.0 | ≤1.2 | |

| Cold Crushing Strength(Mpa) | ≥200 | ≥200 | ≥200 | |

| Bubble Separation Ratio(1300ºC*10h) | ≤1.2 | ≤1.0 | ≤1.0 | |

| Exudation Temperature of Glass Phase(ºC) | ≥1400 | ≥1400 | ≥1410 | |

| Anti-corrosion rate of glass liquid 1500ºC*36h(mm/24h) % | ≤1.4 | ≤1.3 | ≤1.2 | |

| Apparent Density (g/cm3) | PT(RN RC N) | ≥3.55 | ≥3.55 | ≥3.70 |

| ZWS(RR EVF EC ENC) | ≥3.65 | ≥3.75 | ≥3.85 | |

| WS( RT VF EPIC FVP DCL) | ≥3.75 | ≥3.80 | ≥3.95 | |

| QX(RO) | ≥3.65 | ≥3.75 | ≥3.90 | |

Application

| Model | ZrO2 | Application |

| AZS 33 | 33% | The dense microstructure of AZS33 makes the bricks have good resistance to glass liquid erosion, and it is not easy to produce stones or other defects in the glass kiln. It is a widely used product in glass melting furnaces, and is mainly suitable for the upper structure of the melting pool, the pool wall brick and paving brick of the working pool, and the forehearth, etc. |

| AZS 36 | 36% | In addition to having the same eutectic as AZS33, AZS36 bricks have more chain-like zirconia crystals and lower glass phase content, so the corrosion resistance of AZS36 bricks is further enhanced, so it is suitable for glass liquids with faster flow rates. or higher temperature areas. |

| AZS 41 | 41% | In addition to eutectics of silica and alumina, it also contains more uniformly distributed zirconia crystals. In the zirconium corundum brick system, it has good corrosion resistance. Therefore, key parts of the glass furnace are selected to balance the life of these parts with other parts. |

Float Glass

Medicinal Glass

Daily Use Glass

Food Grade Glass

Package&Warehouse

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Robert`s products are widely used in high-temperature kilns such as non-ferrous metals, steel, building materials and construction, chemical, electric power, waste incineration, and hazardous waste treatment. They are also used in steel and iron systems such as ladles, EAF, blast furnaces, converters, coke ovens, hot blast furnaces; non-ferrous metallurgical kilns such as reverberators, reduction furnaces, blast furnaces, and rotary kilns; building materials industrial kilns such as glass kilns, cement kilns, and ceramic kilns; other kilns such as boilers, waste incinerators, roasting furnace, which have achieved good results in using. Our products are exported to Southeast Asia, Central Asia, Middle East, Africa, Europe, Americas and other countries, and has established a good cooperation foundation with multiple well-known steel enterprises. All employees of Robert sincerely look forward to working with you for a win-win situation.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

Are you a manufacturer or a trader?

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

How do you control your quality?

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

What is your delivery time?

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Do you provide free samples?

Of course, we provide free samples.

Can we visit your company?

Yes, of course, you are welcome to visit RBT company and our products.

What is the MOQ for trial order?

There is no limit, we can provide the best suggestion and solution according to your situation.

Why choose us?

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.

Our target is always to satisfy our customers by offering golden support, superior value and high quality for China Manufacturer for Used Fused Zirconium Corundum Refractory Brick for Glass Furnace, To deliver clients with great equipment and companies, and frequently develop new machine is our company’s business objectives. We look ahead for your cooperation.

China Manufacturer for China Fused Refractory Blocks and Azs Block, Our company considers that selling is not only to gain profit but also popularize the culture of our company to the world. So we have been working hard to give you the wholehearted service and willing to provide you the most competitive price in the market