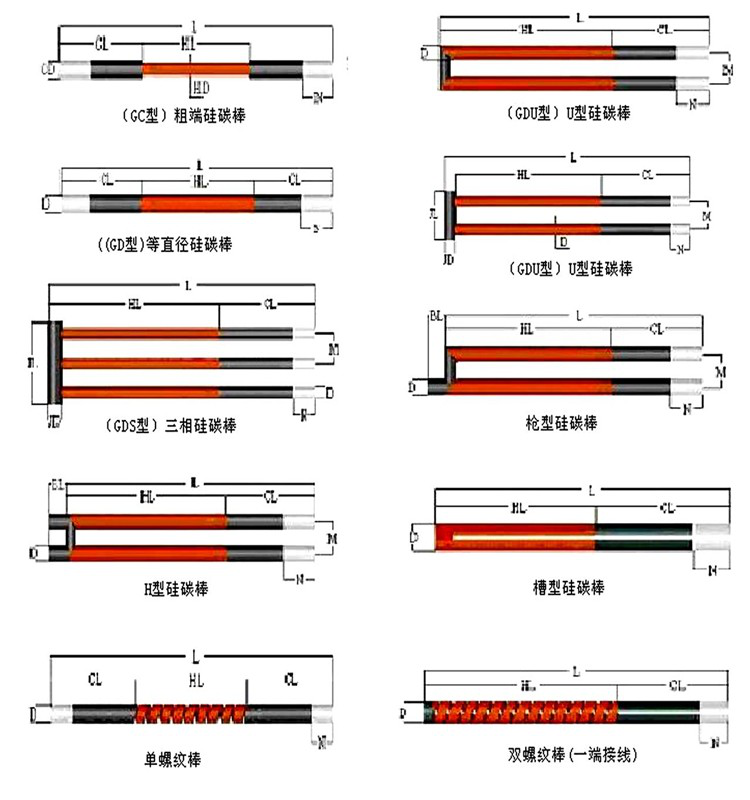

Silicon Carbide Rod Series

|

Product Name

|

Silicon Carbide Rod

|

||

|

Description

|

1. Silicon carbide rods are rod-shaped and tubular non-metallic high-temperature electric heating elements made of high-purity green hexagonal silicon carbide as the main raw material, processed into blanks according to a certain material ratio, and sintered at 2200°C for high-temperature siliconization, recrystallization and sintering.

2. The normal use temperature in an oxidizing atmosphere can reach 1450°C, and the continuous use can reach 2000 hours.

|

||

|

Model

|

GD(Equal diameter rod); GC (Butt end rod); GDC (U-shaped rod); GDQ (Gun type rod); GDH (H type rod); Mini rod; Custom rods

|

||

|

Density

|

2.6 g/cm3

|

Moh's hardness

|

9.5

|

|

Specific Heat

|

0.17 kcal/kg·degree

|

Thermal Conductivity

|

20kcal/m·hour·degree

|

|

Linear Expansion Coefficient

|

5×10-6(m/℃)

|

Shape

|

Straight/U/W/H/Spiral

|

|

Working Temperature Range

|

800℃ - 1500℃

|

Sic Content

|

99% min

|

|

Features

|

1. High temperature resistance;

2. Oxidation resistance;

3. Corrosion resistance;

4. Fast heating;

5. Long life;

6. Small deformation at high temperature;

7. Easy installation and maintenance.

|

||

|

Application

|

Electric heating element

|

||

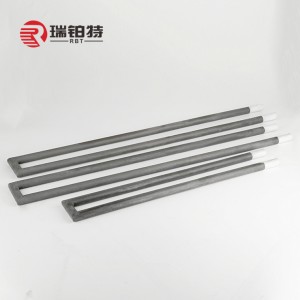

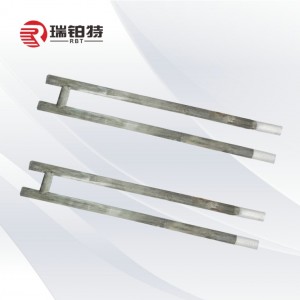

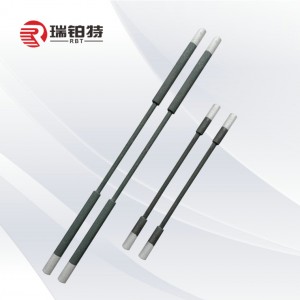

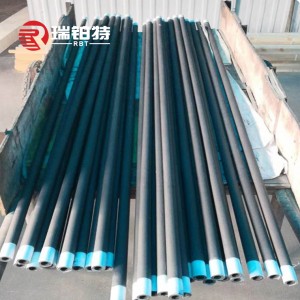

Details Images

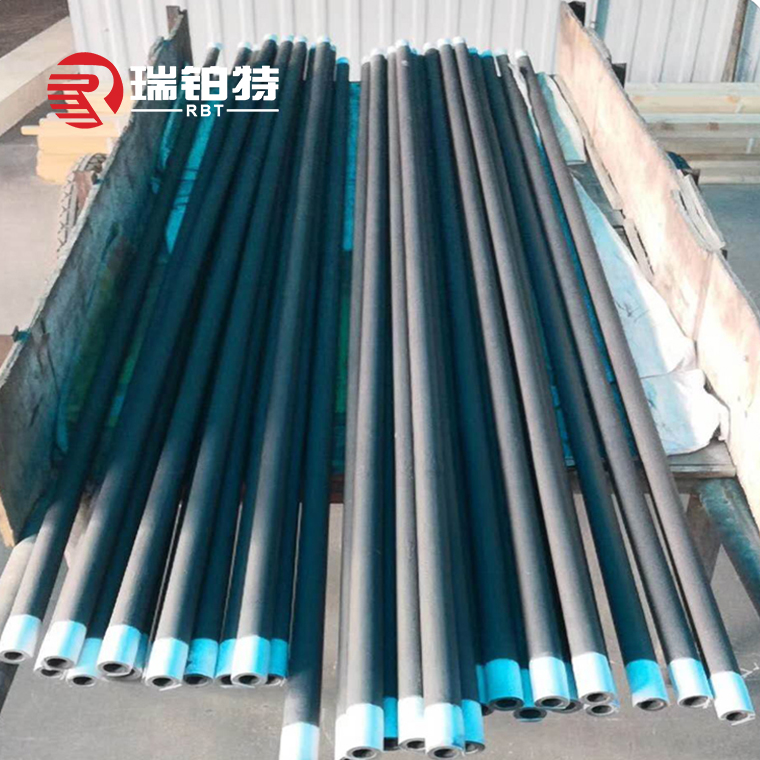

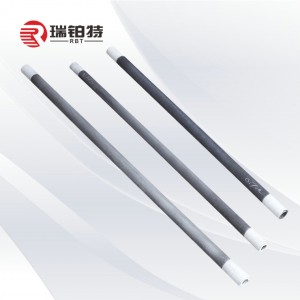

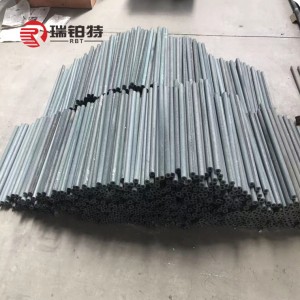

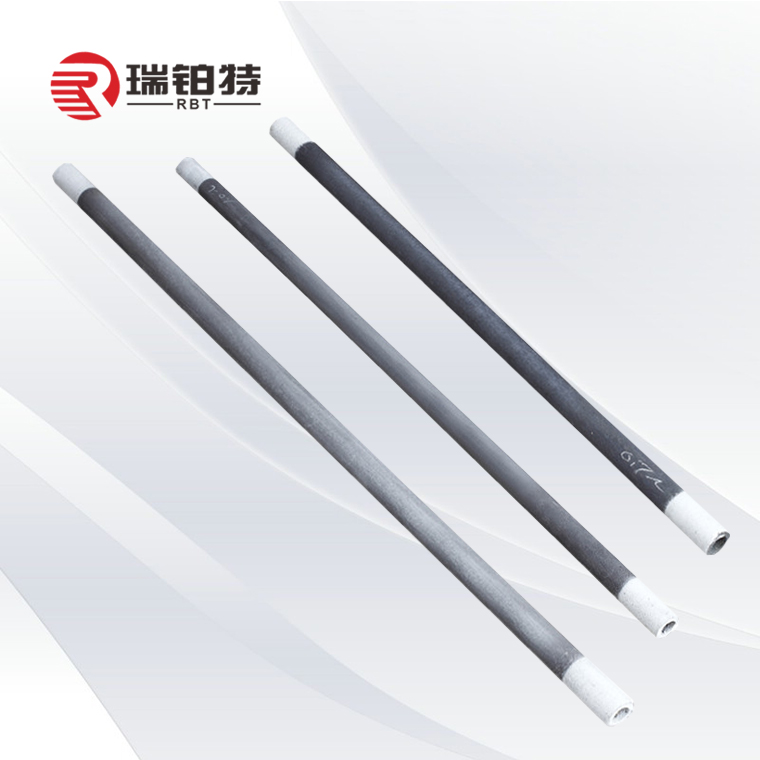

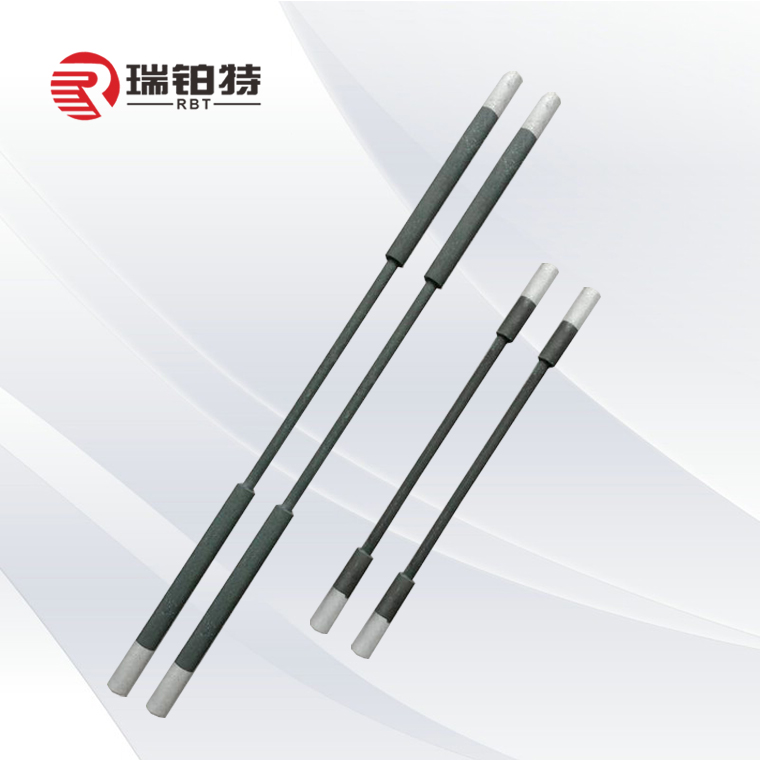

GD (Equal Diameter Silicon Carbide Rod)

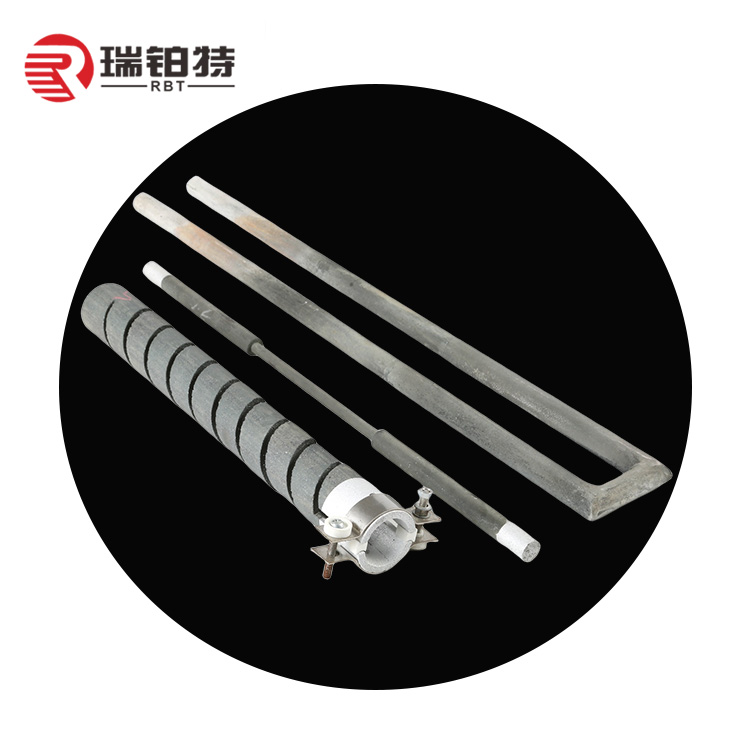

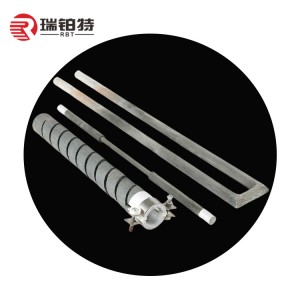

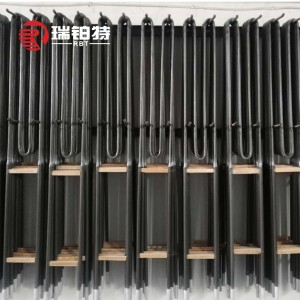

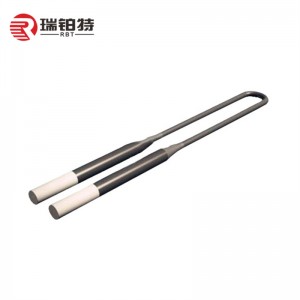

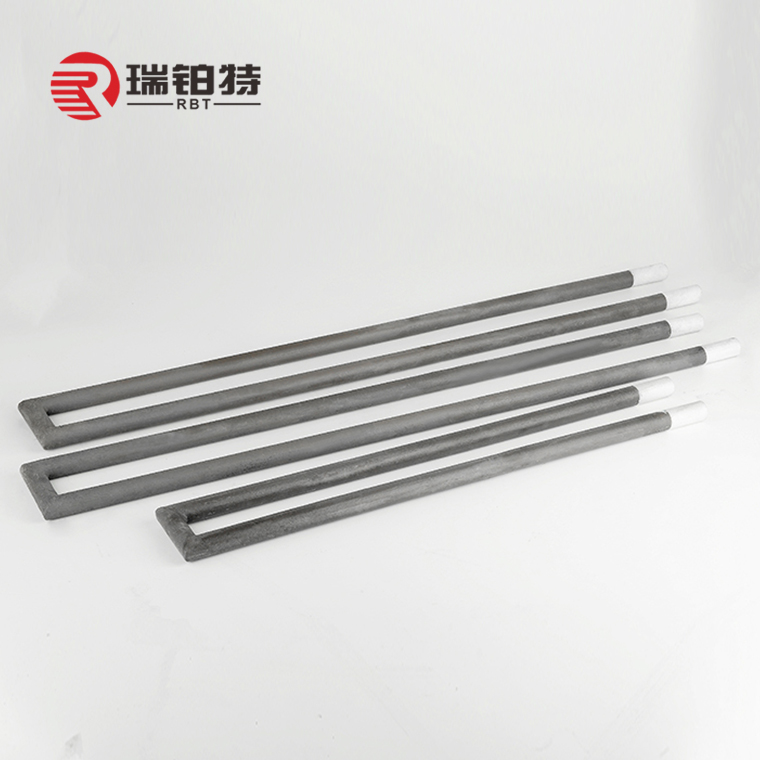

GDC (U-shaped Silicon Carbide Rod)

GC (Dumbbell Silicon Carbide Rod)

Right Angle Silicon Carbide Rod

Silicon Carbide Rod Combination

GDQ (Gun Type Silicon Carbide Rod)

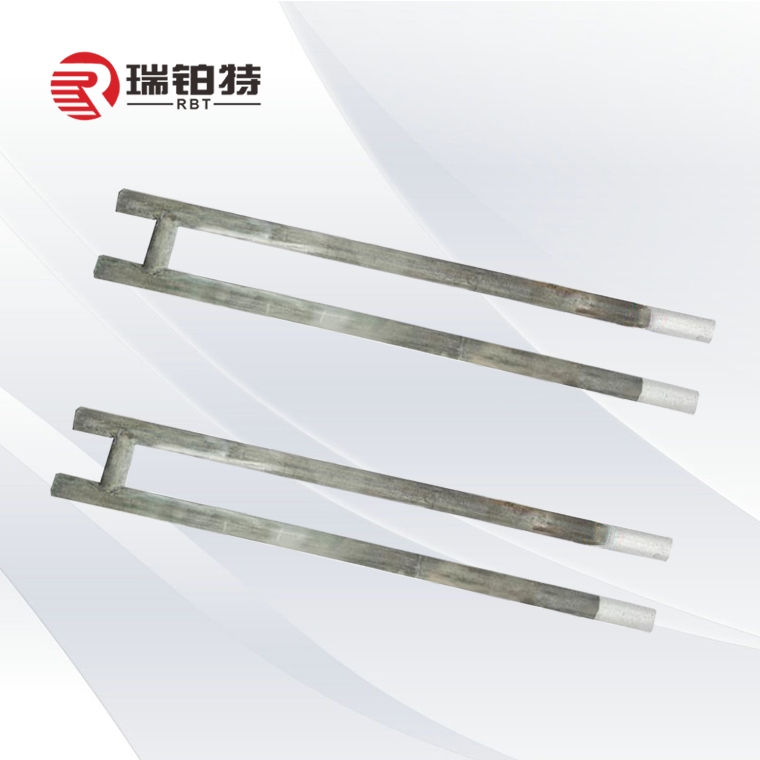

GDH (H-type Silicon Carbide Rod)

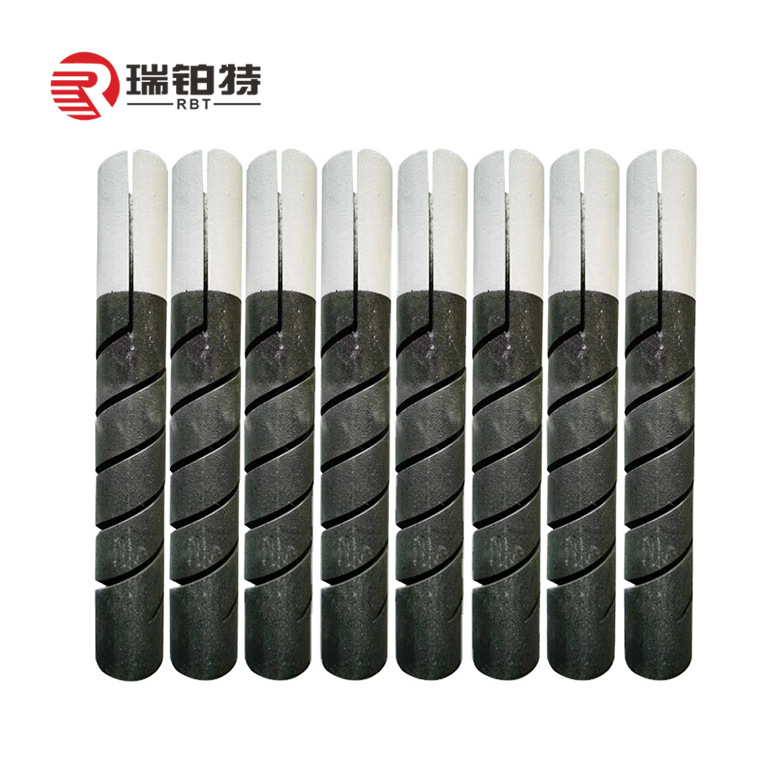

Spiral Silicon Carbide Rod

Gate Type Silicon Carbide Rod

Silicon Carbide Rod Combination

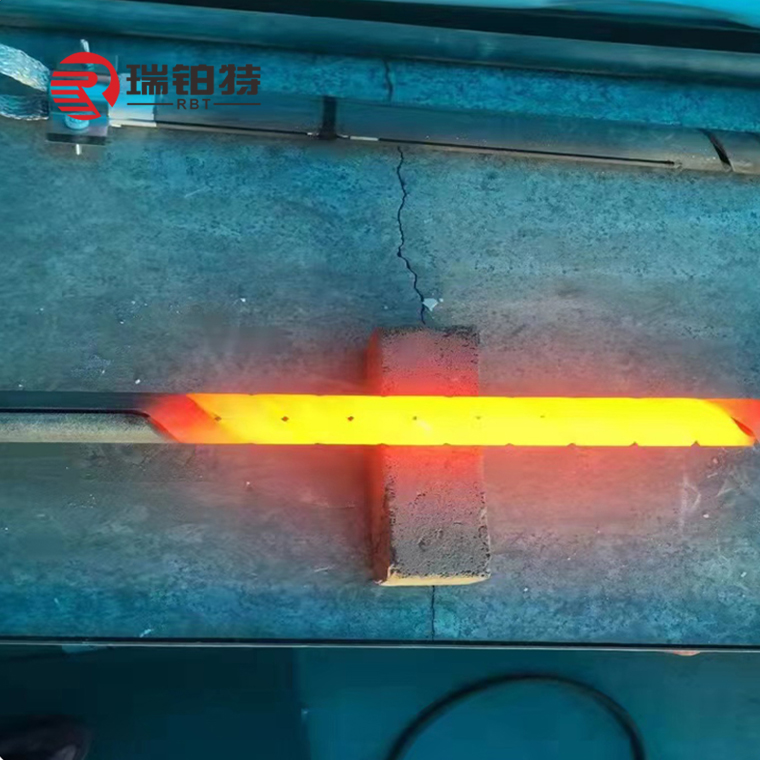

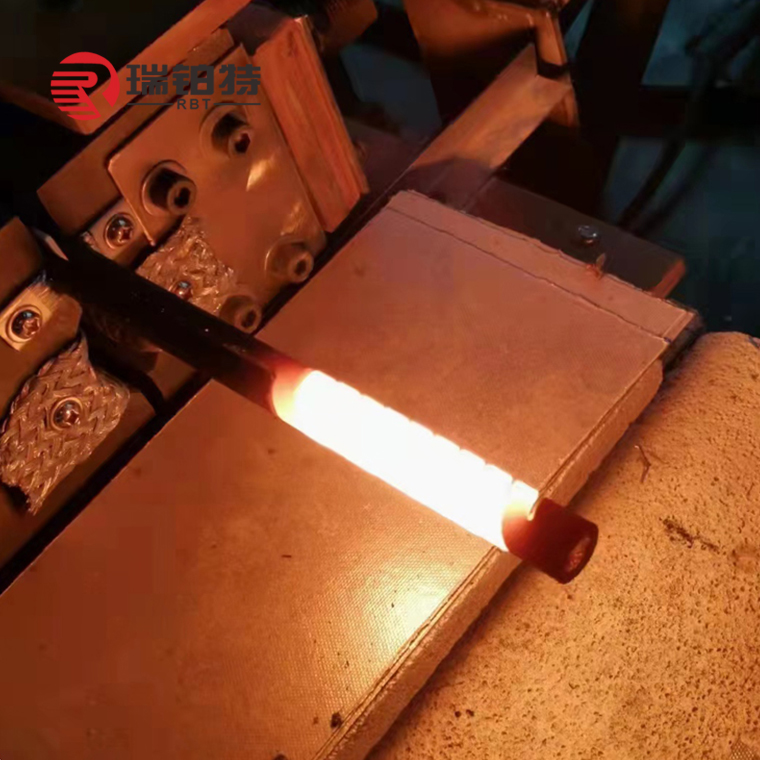

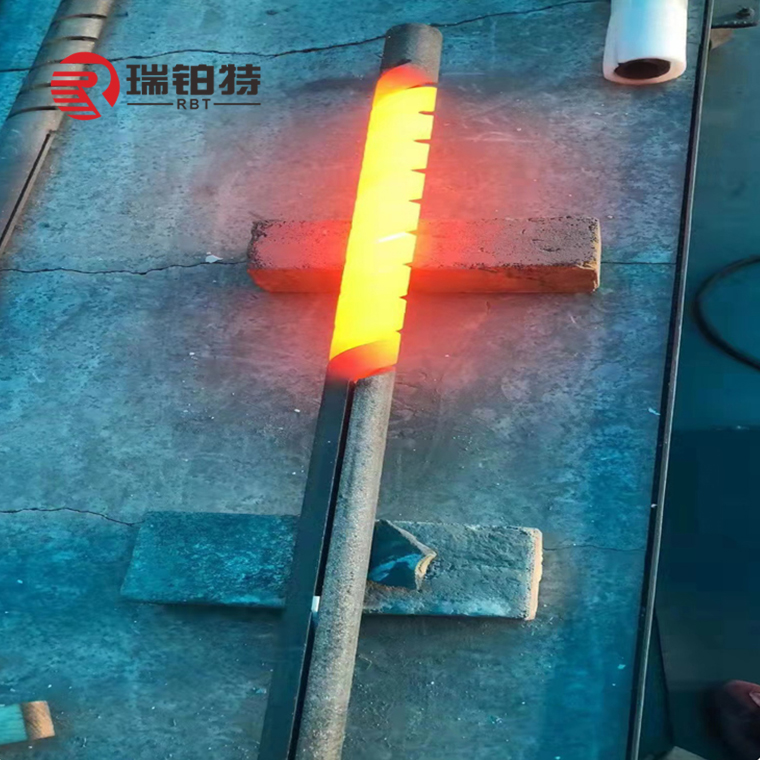

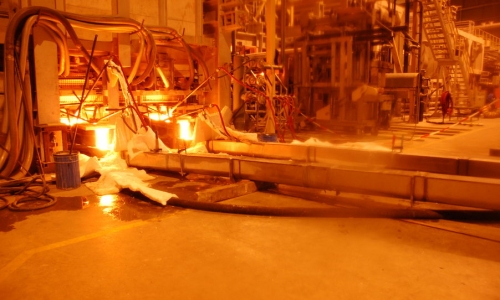

Effect Display

Product Index

|

Item

|

Unit

|

Date

|

|

Content of SiC

|

%

|

99

|

|

Content of SiO2

|

%

|

0.5

|

|

Content of Fe2O3

|

%

|

0.15

|

|

Content of C

|

%

|

0.2

|

|

Density

|

g/cm3

|

2.6

|

|

Apparent Porosity

|

%

|

<18

|

|

Pressure-resisting Strength

|

Mpa

|

≥120

|

|

Bending Strength

|

Mpa

|

≥80

|

|

Operating Temperature

|

℃

|

≤1600

|

|

Coefficient of Thermal Expansion

|

10 -6/℃

|

<4.8

|

|

Thermal Conductivity

|

J/Kg℃

|

1.36*10

|

Application

Widely used in high-temperature fields such as electronics, magnetic materials, powder metallurgy, ceramics, glass,

semiconductors, analysis and testing, and scientific research, and has become a tunnel kiln, roller kiln, glass kiln, vacuum

furnace, muffle furnace, smelting furnace and electric heating elements for heating equipment.

Glass Furnace

Roller Kiln

Tunnel Kiln

Smelting Furnace

Package&Warehouse