Glass Wool Pipe

Product Information

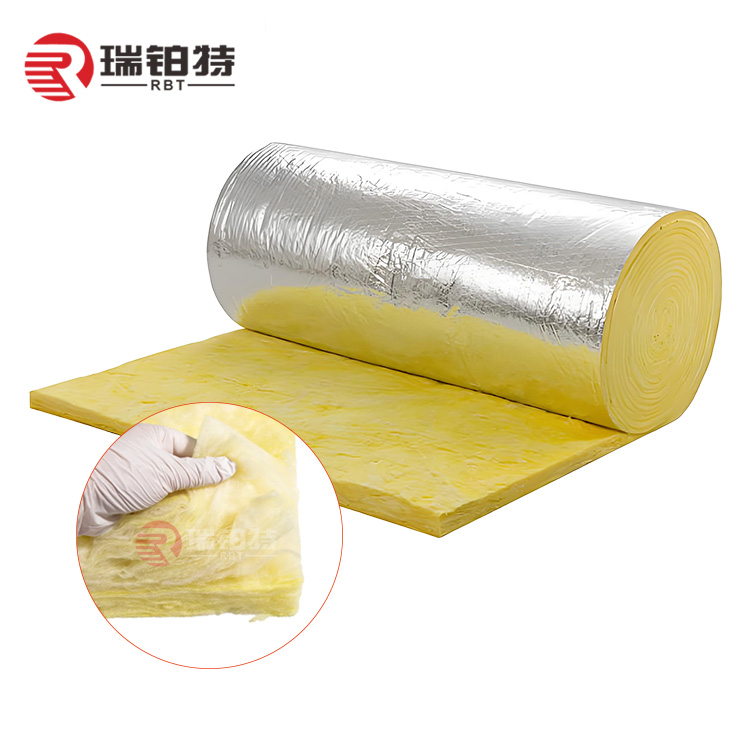

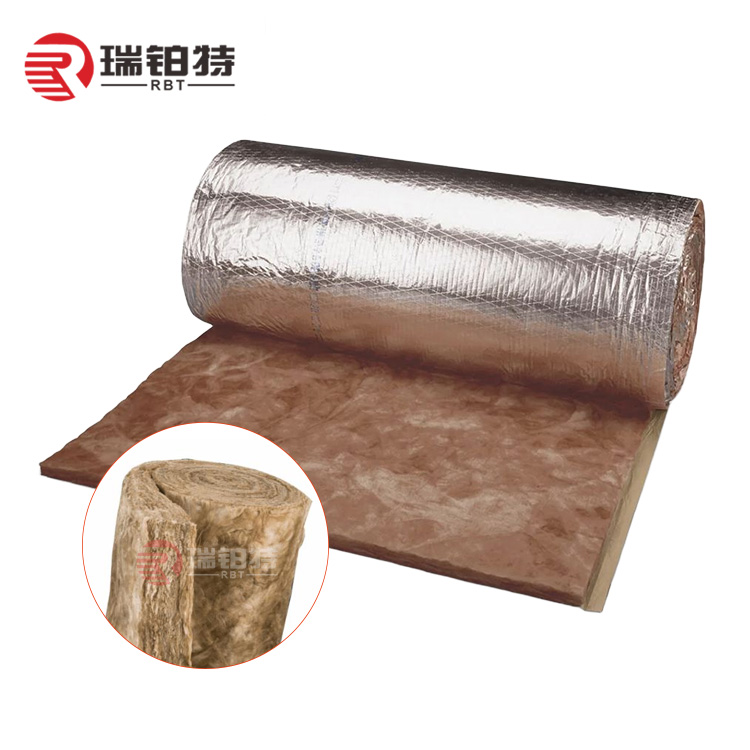

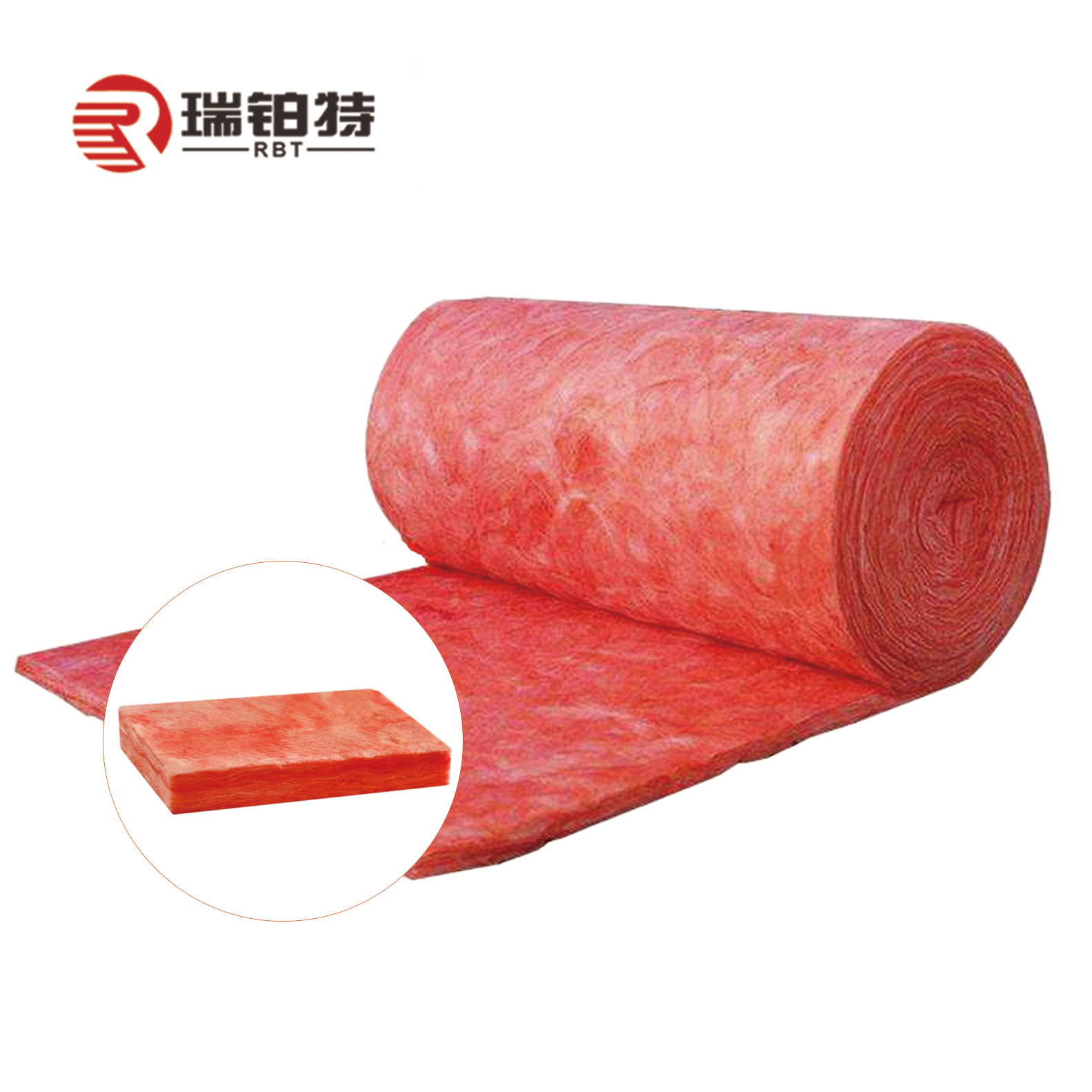

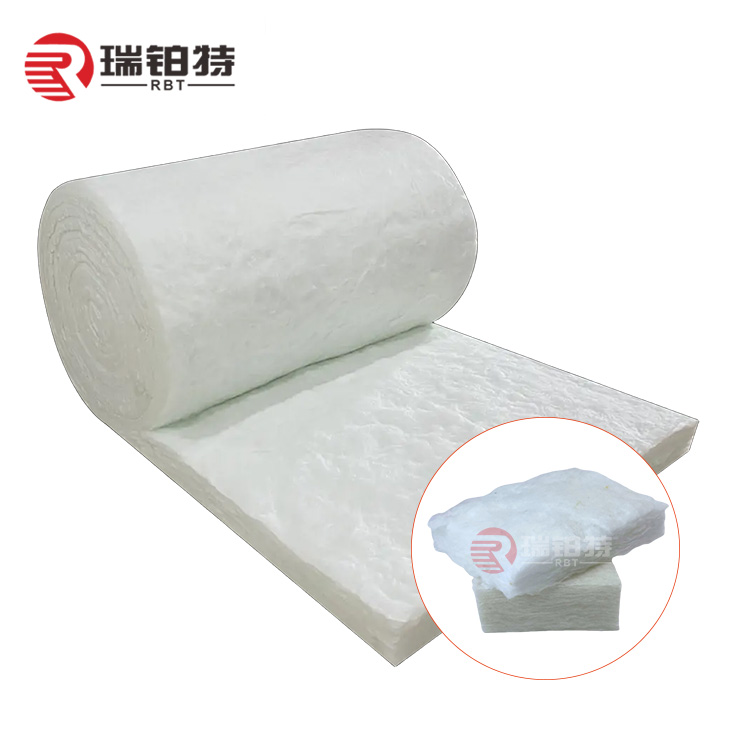

Glass wool roll is a cotton-like material formed by molten glass fiberization. During the manufacturing process, natural minerals such as quartz sand, limestone, dolomite, etc. are mixed with some chemical raw materials such as soda ash and borax to melt into glass, and then the molten state is blown or thrown into flocculent fine fibers with the help of external force to form a glass wool blanket.

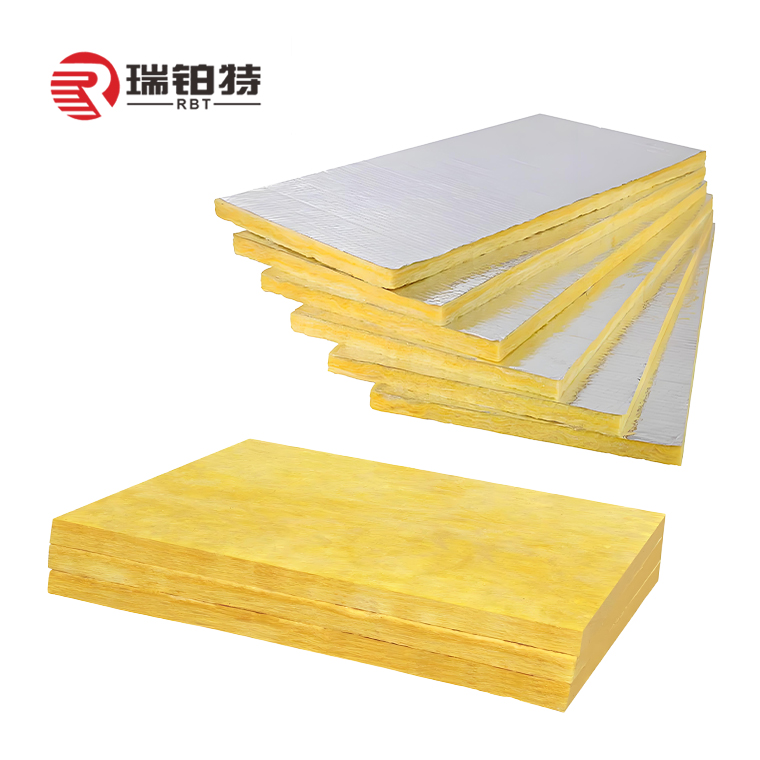

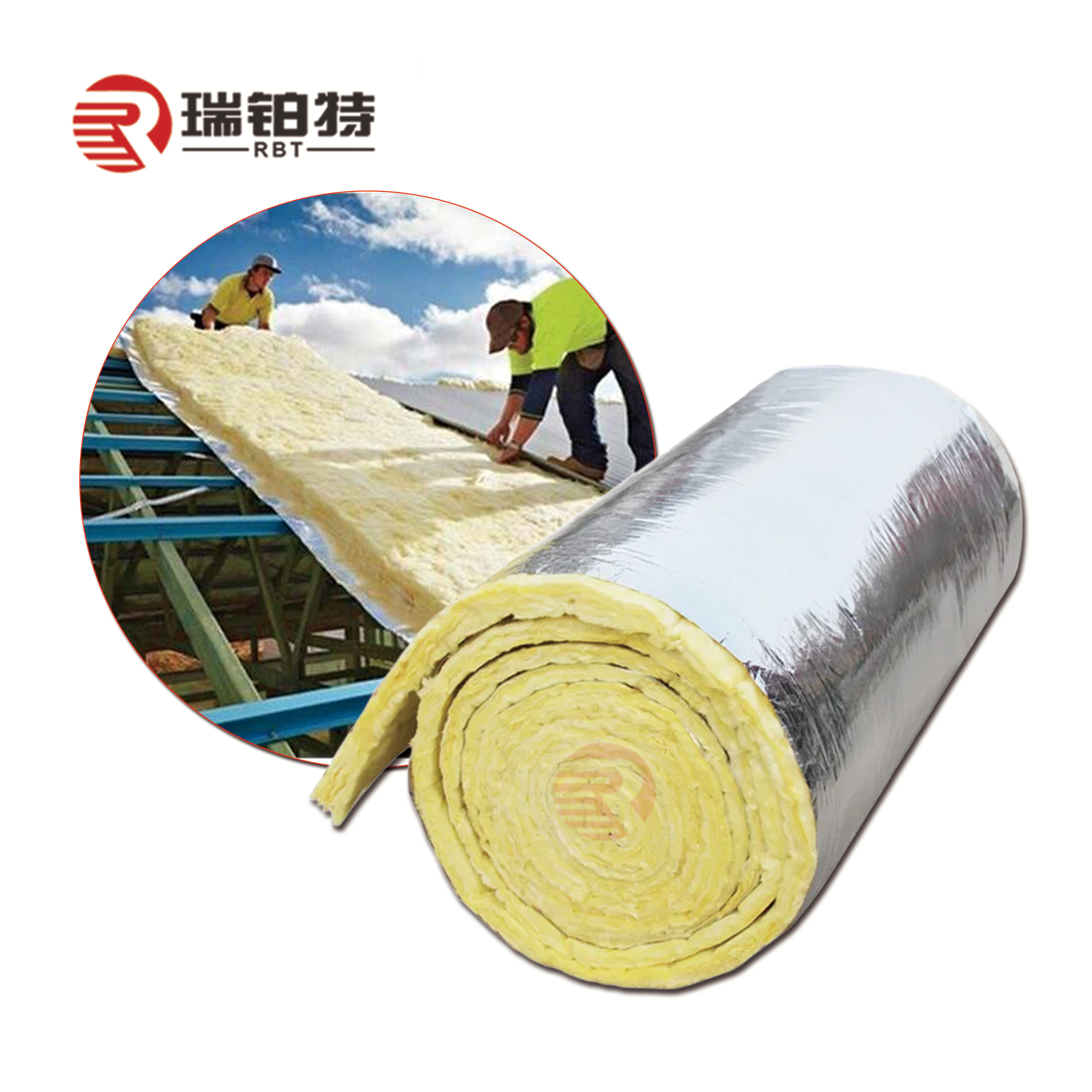

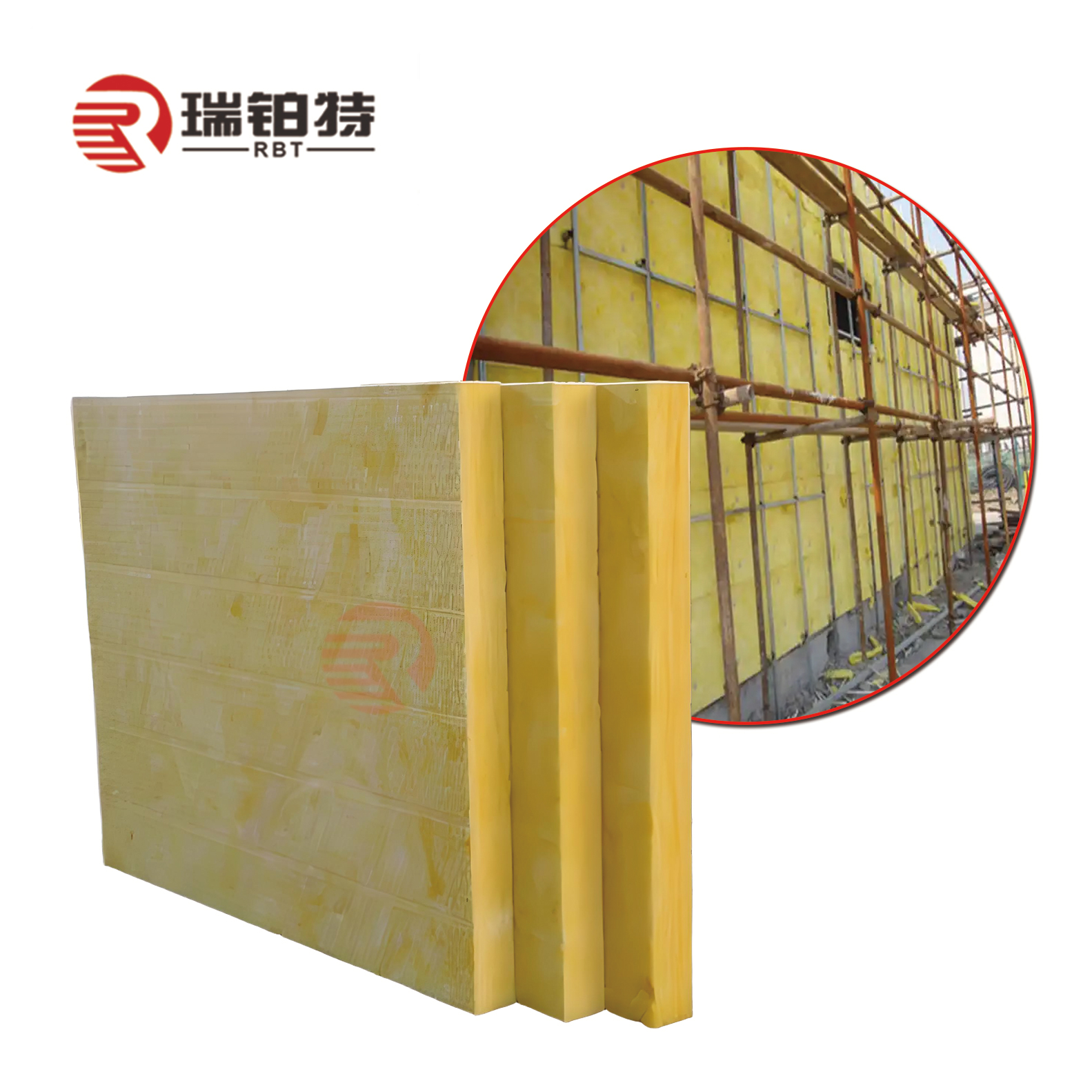

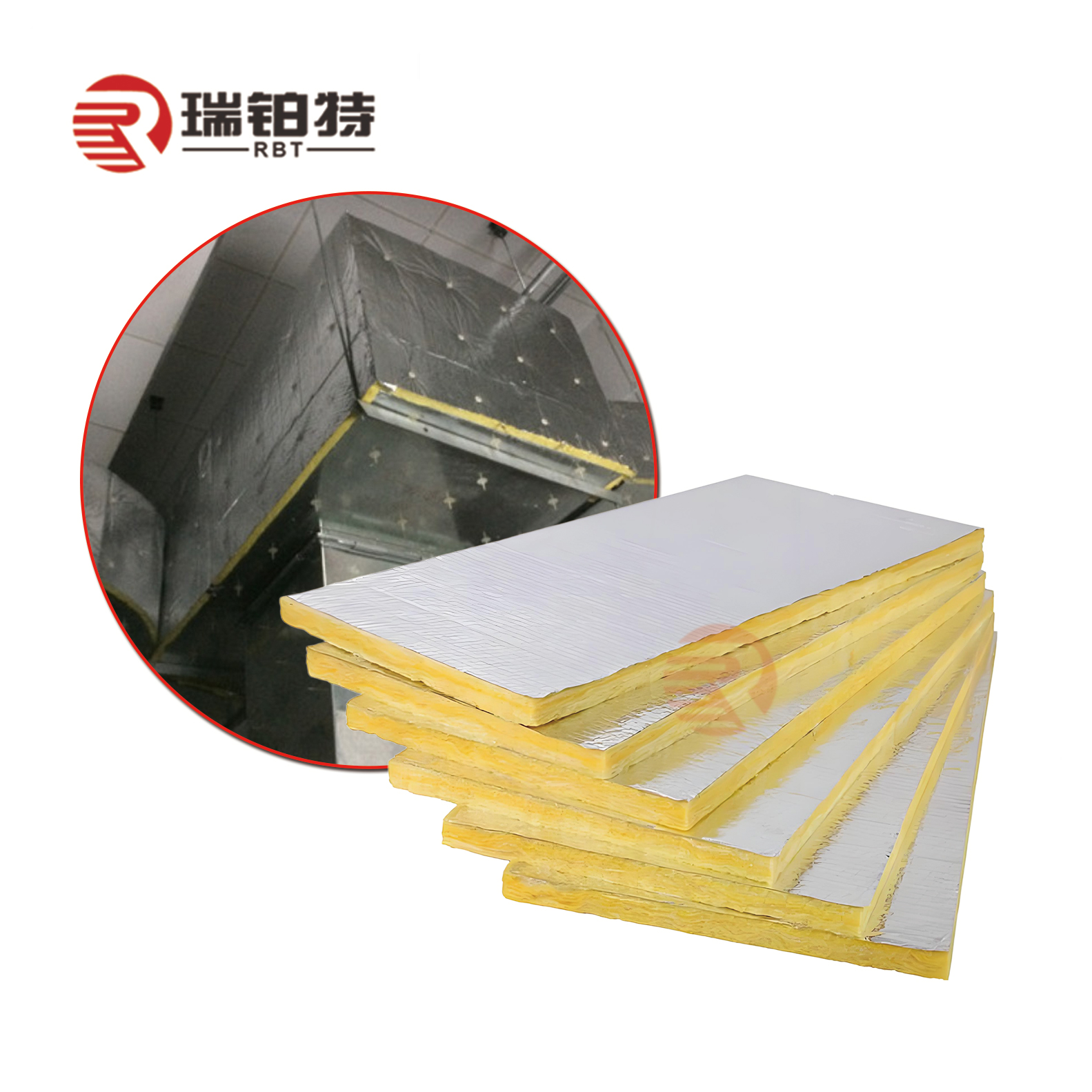

Glass wool board is a building material made of glass fiber, which has excellent thermal insulation, sound insulation and fireproof properties. It is made by melting glass at high temperature, pulling it into fibers using a centrifugal blowing process, and then adding adhesives and curing it at high temperature. Glass wool board is famous for its low thermal conductivity, porous structure and fireproof performance.

Features:

Excellent thermal insulation; Good sound absorption and noise reduction;

Excellent fire resistance; Environmentally friendly and safe.

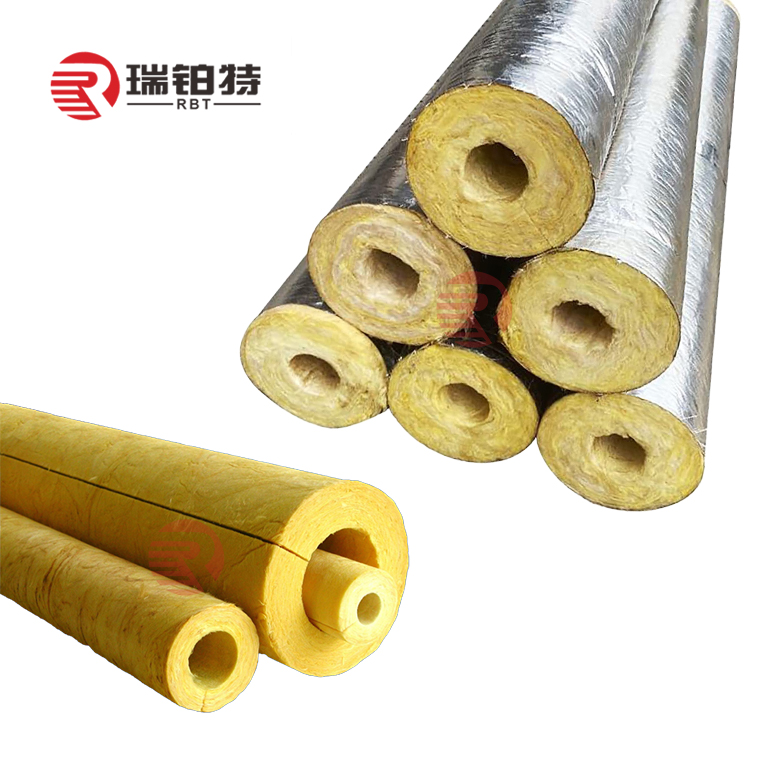

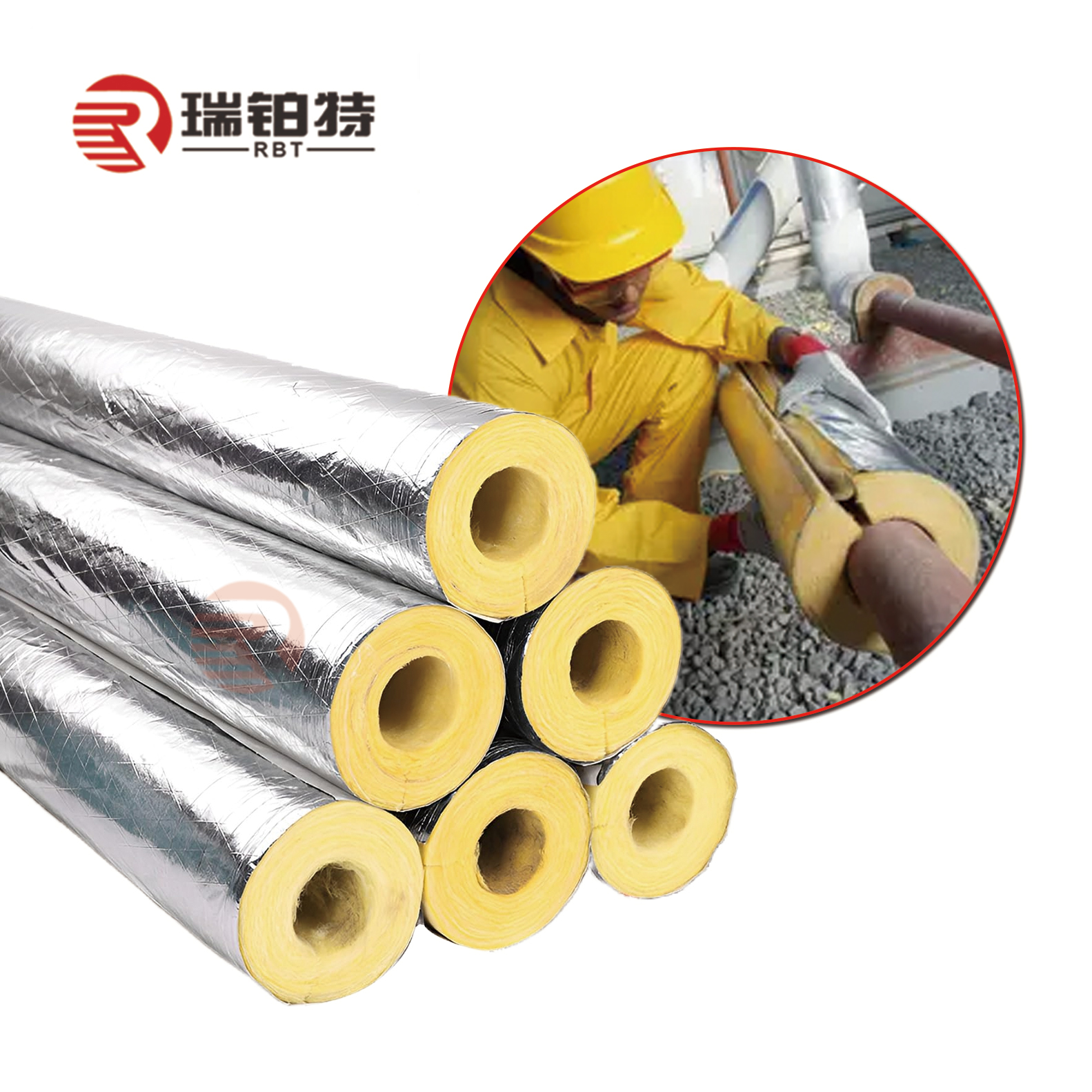

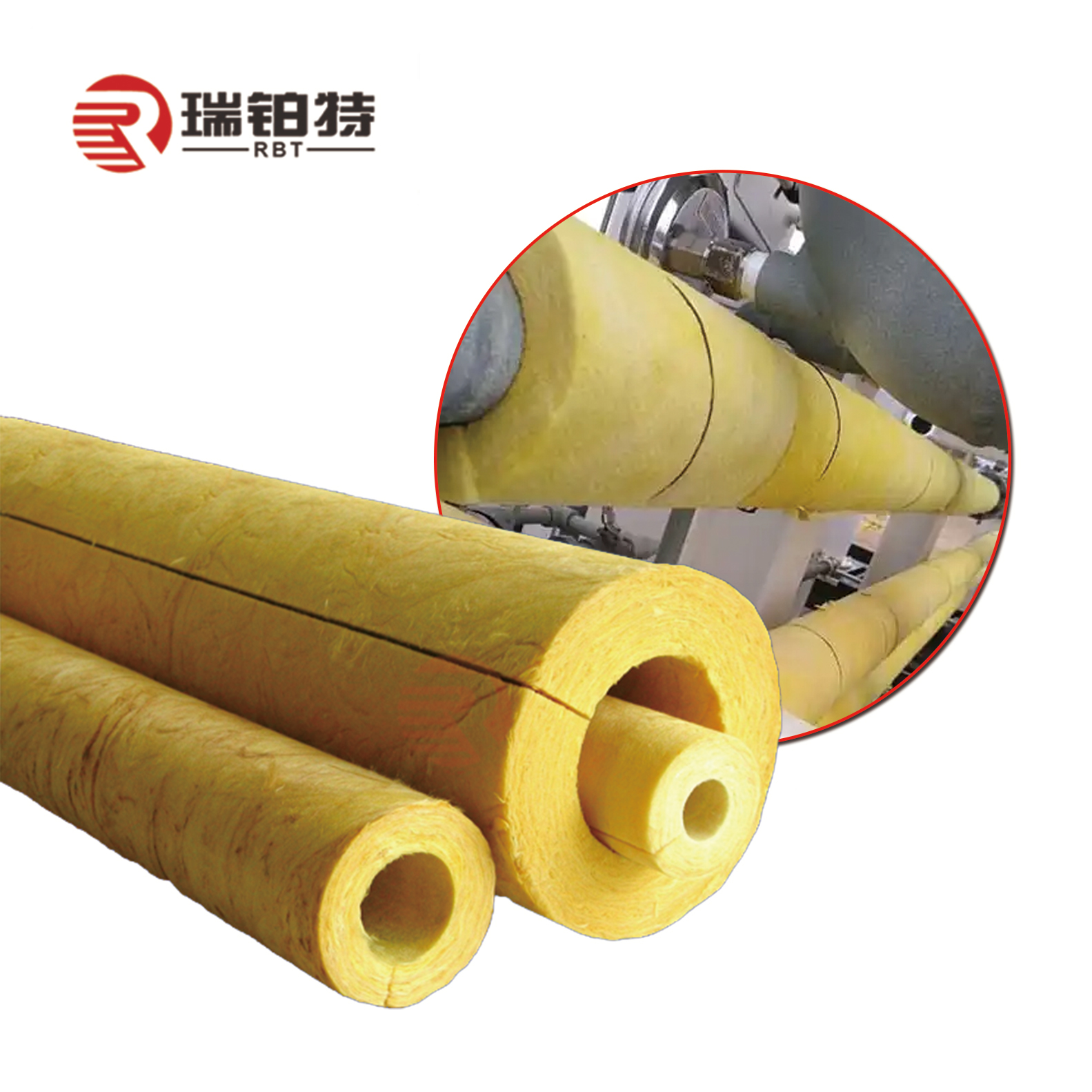

Glass wool pipe is a thermal insulation material made of ultra-fine glass wool, which is cured by heating with a resin adhesive. It has excellent thermal insulation properties, can effectively prevent heat transfer, reduce energy loss, and improve system energy efficiency.

Features:

High insulation efficiency; Corrosion and high temperature resistance;

Waterproof, anti-corrosion, mildew-proof, and insect-proof;

Lightweight and high durability; Good environmental protection.

Details Images

|

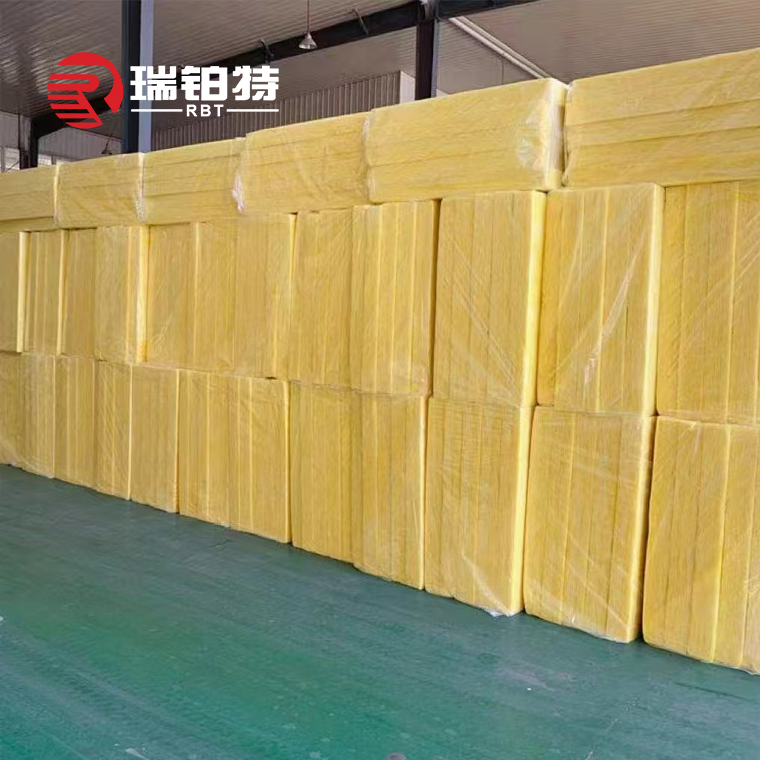

Glass Wool Board |

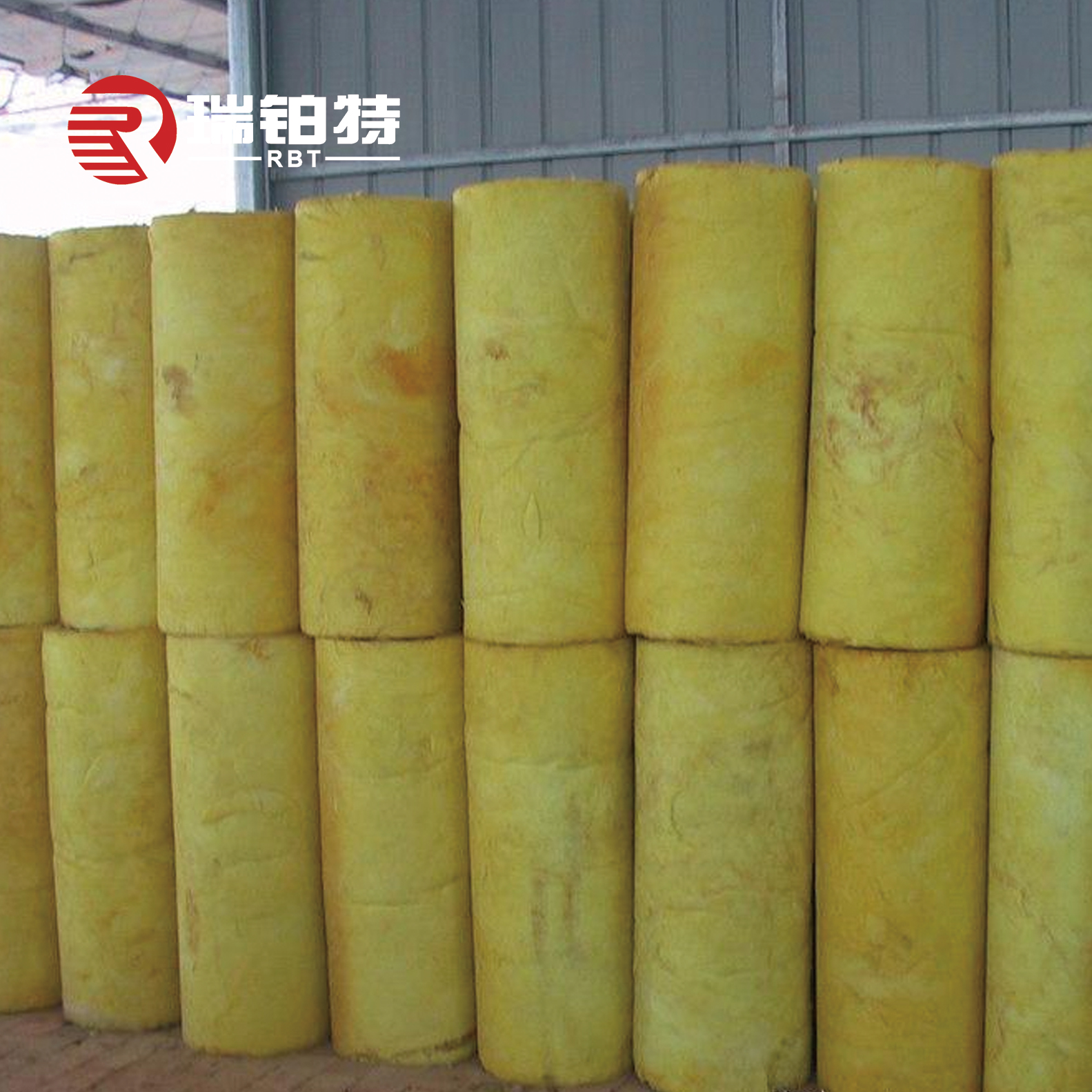

Glass Wool Roll |

Glass Wool Pipe |

|||

|

Density |

24-96kg/m3 |

Density |

10-48kg/m3 |

Density |

40-80kg/m3 |

|

Thickness |

25-100mm |

Thickness |

25-150mm |

Inner diameter |

27-1220mm |

|

Length |

60-2400mm |

Length |

3-20m |

Thickness |

30-100mm |

|

Width |

600-1200mm |

Width |

1200mm |

||

Glass Wool Board

Can be covered with aluminum foil

Glass Wool Pipe

Can be covered with aluminum foil

Product Index

|

Item

|

unit

|

Index

|

|

Density

|

kg/m3

|

10-80

|

|

Average Fiber Diameter

|

um

|

5.5

|

|

Moisture Content

|

%

|

≤1

|

|

Combustion Performance Level

|

|

Non-flammable Class A

|

|

Thermal Load Collection Temperature

|

℃

|

250-400

|

|

Thermal Conductivity

|

w/m.k

|

0.034-0.06

|

|

Water Repellency

|

%

|

≥98

|

|

Hygroscopicity

|

%

|

≤5

|

|

Sound Absorption Coefficient

|

|

24kg/m3 2000HZ

|

|

Slag Ball Content

|

%

|

≤0.3

|

|

Safe Use Temperature

|

℃

|

-120-400

|

Application

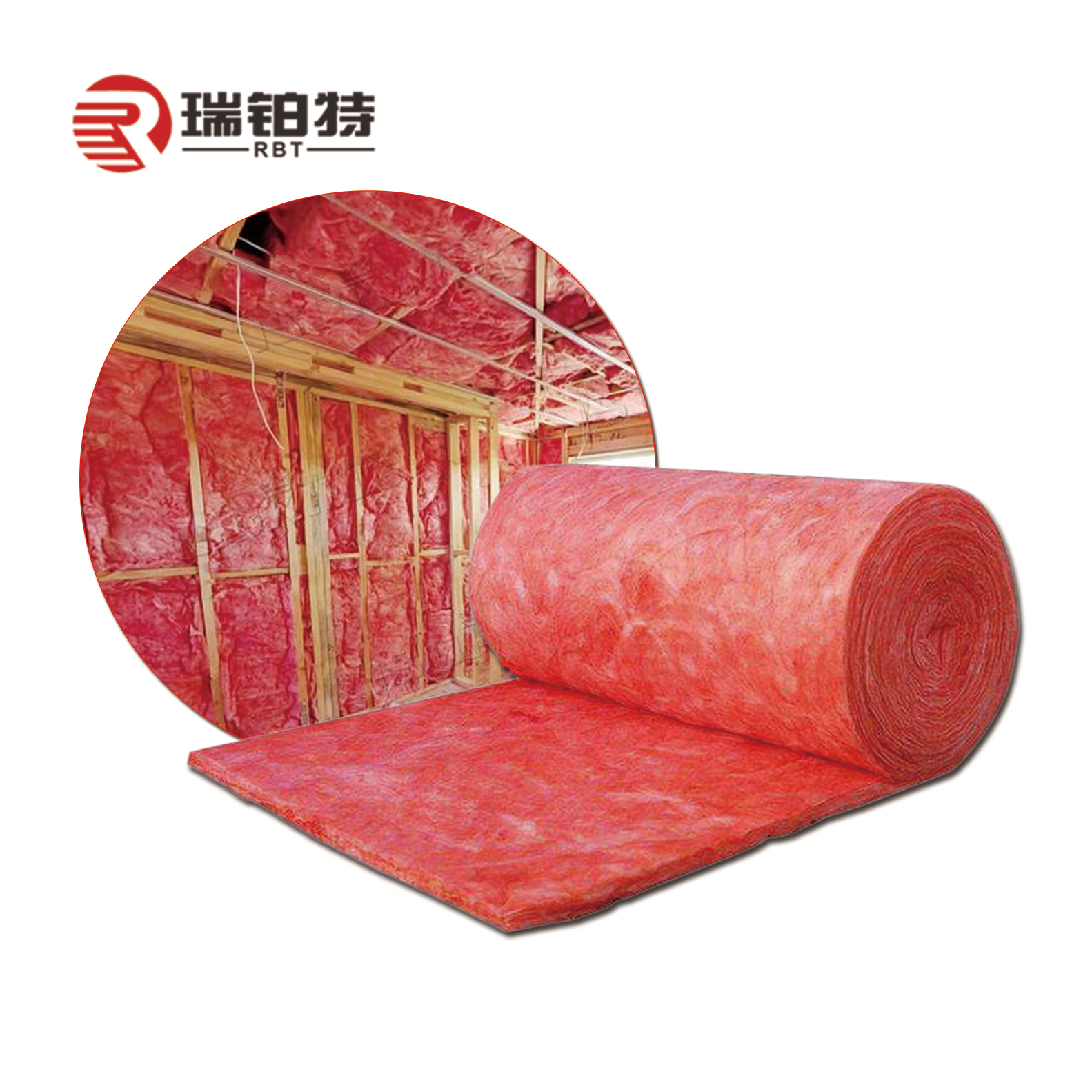

Glass Wool Rolls:

1. Architectural field: used for heat and sound insulation of walls, ceilings, floors, etc., as well as heat preservation of air conditioners and pipes. Compared with traditional insulation materials, glass wool blankets have better heat preservation performance and can effectively reduce energy consumption.

2. Ship field: used for compartments, heat preservation, heat insulation and noise reduction treatment to improve the safety and comfort of ships.

3. Automobile field: used for heat insulation, noise reduction and heat preservation of car bodies and engines, with higher fire resistance and stable heat preservation performance, while reducing the vibration and noise of the car chassis.

4. Home appliance field: used for heat insulation, heat preservation and noise reduction of refrigerators, air conditioners and other products, reducing energy consumption and improving noise isolation effect.

Glass wool board is widely used in construction, industry and transportation. In construction, it is used for thermal insulation, heat insulation and sound insulation of exterior walls, interior walls, ceilings and floors; in industry, it is used for thermal insulation of equipment and pipelines; in transportation, it is used for sound insulation of cars, trains and airplanes. The installation of glass wool board is relatively simple, suitable for the thermal insulation and sound insulation needs of large flat areas. It can be flexibly cut and fit different surface structures according to the needs of the building, which is convenient for transportation and installation.

The application field of glass wool pipe is very wide, including heating systems and air-conditioning systems in the construction field, chemical, power and metallurgical pipeline systems in the industrial field, and ventilation and drainage pipes of transportation facilities. In addition, it is also used in agriculture and medical fields to provide thermal insulation, heat insulation and noise reduction effects. In terms of installation and maintenance, glass wool tubes are easy to cut and adapt to different sizes and shapes, suitable for the thermal insulation needs of various pipeline systems. At the same time, it is necessary to pay attention to handling with care and avoid storage in a humid or direct sunlight environment to ensure that its performance is not affected.

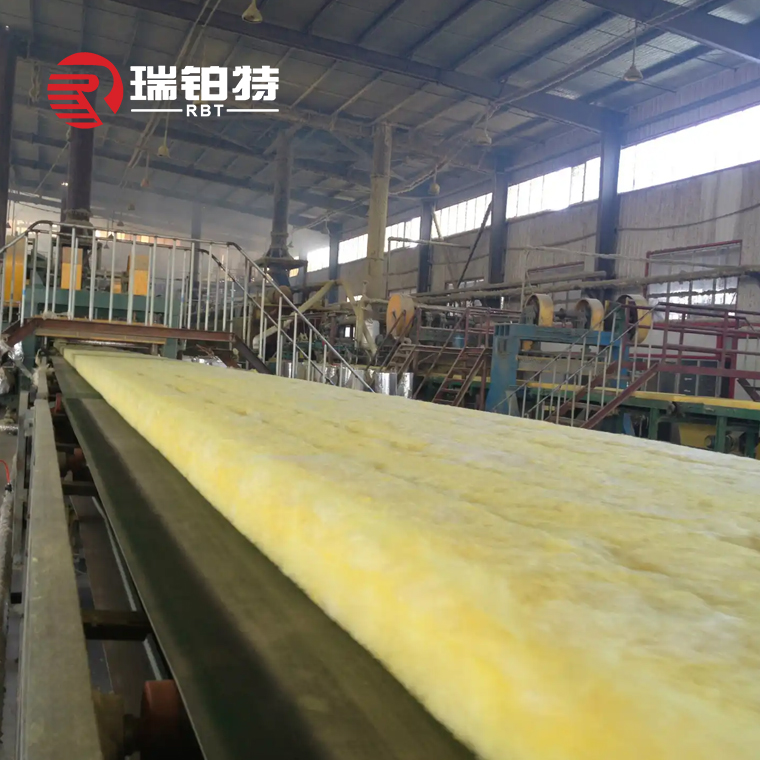

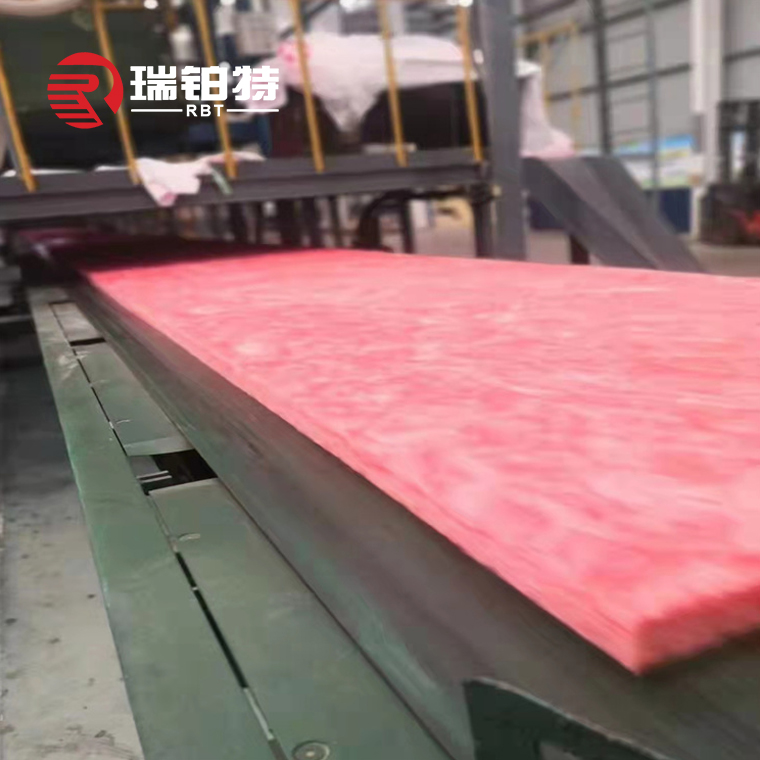

Production Line

Package&Warehouse

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.