Green Silicon Carbide

Product Information

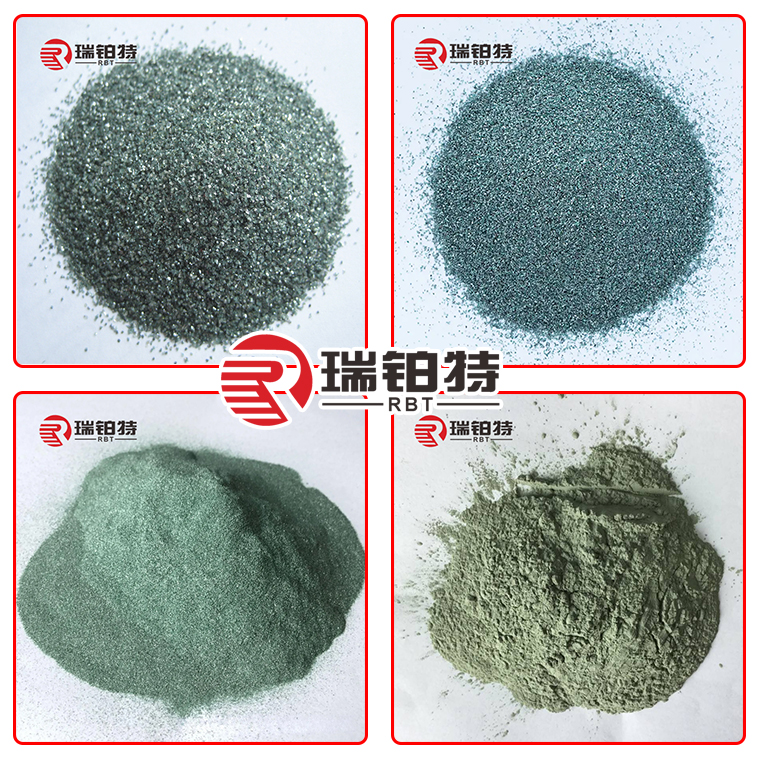

Green silicon carbide sand is a man-made abrasive with a chemical formula of SiC. It is mainly made of quartz sand, petroleum coke (or coal coke) and sawdust through high-temperature smelting in a resistance furnace. Green silicon carbide sand is green in color and has many significant characteristics and applications.

Processing performance

High grinding efficiency: The particle shape and hardness make it have excellent grinding efficiency, which can quickly remove dirt and oxide layer on the surface of the workpiece.

Good self-sharpening property: The particle size and shape are equal and have a blade edge, which ensures its balanced self-sharpening property as a cutting blade material and ensures the minimization of the cut material.

Good adaptability: It can be well adapted to a variety of cutting fluids to improve processing efficiency and quality.

Physic Properties

|

Color

|

Green

|

|

Crystal Form

|

Polygon

|

|

Mohs Hardness

|

9.2-9.6

|

|

Micro Hardness

|

2840~3320kg/mm²

|

|

Melting Point

|

1723

|

|

Maximum Operating Temperature

|

1600

|

|

True Density

|

3.21g/cm³

|

|

Bulk Density

|

2.30g/cm³

|

Details Images

Grit Size Comparison Chart

|

Grit No. |

China GB2477-83 |

Japan JISR 6001-87 |

U.S.A ANSI(76) |

欧洲磨料 FEPA(84) |

国际ISO(86) |

|

4 |

5600-4750 |

|

5600-4750 |

5600-4750 |

5600-4750 |

|

5 |

4750-4000 |

|

4750-4000 |

4750-4000 |

4750-4000 |

|

6 |

4000-3350 |

|

4000-3350 |

4000-3350 |

4000-3350 |

|

7 |

3350-2800 |

|

3350-2800 |

3350-2800 |

3350-2800 |

|

8 |

2800-2360 |

2800-2360 |

2800-2360 |

2800-2360 |

2800-2360 |

|

10 |

2360-2000 |

2360-2000 |

2360-2000 |

2360-2000 |

2360-2000 |

|

12 |

2000-1700 |

2000-1700 |

2000-1700 |

2000-1700 |

2000-1700 |

|

14 |

1700-1400 |

1700-1400 |

1700-1400 |

1700-1400 |

1700-1400 |

|

16 |

1400-1180 |

1400-1180 |

1400-1180 |

1400-1180 |

1400-1180 |

|

20 |

1180-1000 |

1180-1100 |

1180-1000 |

1180-1000 |

1180-1000 |

|

22 |

1000-850 |

- |

- |

1000-850 |

1000-850 |

|

24 |

850-710 |

850-710 |

850-710 |

850-710 |

850-710 |

|

30 |

710-600 |

710-600 |

710-600 |

710-600 |

710-600 |

|

36 |

600-500 |

600-500 |

600-500 |

600-500 |

600-500 |

|

40 |

500-425 |

- |

- |

500-425 |

500-425 |

|

46 |

425-355 |

425-355 |

425-355 |

425-355 |

425-355 |

|

54 |

355-300 |

355-300 |

355-297 |

355-300 |

355-300 |

|

60 |

300-250 |

300-250 |

297-250 |

300-250 |

300-250 |

|

70 |

250-212 |

250-212 |

250-212 |

250-212 |

250-212 |

|

80 |

212-180 |

212-180 |

212-180 |

212-180 |

212-180 |

|

90 |

180-150 |

180-150 |

180-150 |

180-150 |

180-150 |

|

100 |

150-125 |

150-125 |

150-125 |

150-125 |

150-125 |

|

120 |

125-106 |

125-106 |

125-106 |

125-106 |

125-106 |

|

150 |

106-75 |

106-75 |

106-75 |

106-75 |

106-75 |

|

180 |

90-63 |

90-63 |

90-63 |

90-63 |

90-63 |

|

220 |

75-53 |

75-53 |

75-53 |

75-53 |

75-53 |

|

240 |

75-53 |

- |

75-53 |

- |

Product Index

|

Grit Size

|

Chemical Composition% (By Weight)

|

||

|

SiC

|

F·C

|

Fe2O3

|

|

|

12#-90#

|

≥98.50

|

≤0.20

|

≤0.60

|

|

100#-180#

|

≥98.00

|

≤0.30

|

≤0.80

|

|

220#-240#

|

≥97.00

|

≤0.30

|

≤1.20

|

|

W63-W20

|

≥96.00

|

≤0.40

|

≤1.50

|

|

W14-W5

|

≥93.00

|

≤0.40

|

≤1.70

|

Application

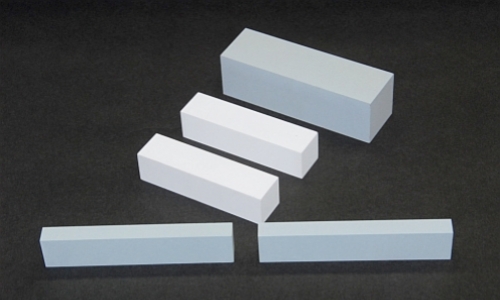

1. Abrasive: Green silicon carbide is widely used as an abrasive material in various industries, including automotive, aerospace, metalworking, and jewelry. It is used for grinding, cutting, and polishing of hard metals and ceramics.

2. Refractory: Green silicon carbide is also used as a refractory material in high-temperature applications such as furnaces and kilns due to its high thermal conductivity and low thermal expansion.

3. Electronics: Green silicon carbide is used as a substrate material for electronic devices such as LEDs, power devices, and microwave devices due to its excellent electrical conductivity and thermal stability.

4. Solar energy: Green silicon carbide is used as a material for manufacturing solar panels due to its high thermal conductivity and low thermal expansion, which helps in dissipating heat generated during the operation of solar panels.

5. Metallurgy: Green silicon carbide is used as a deoxidizing agent in the production of iron and steel. It helps in removing impurities from the molten metal and improving the quality of the final product.

6. Ceramics: Green silicon carbide is used as a raw material for manufacturing advanced ceramics such as cutting tools, wear-resistant parts, and high-temperature components due to its high hardness, high strength, and excellent thermal stability.

Package&Warehouse

|

Package

|

25KG Bag

|

1000KG Bag

|

|

Quantity

|

24-25 Tons

|

24 Tons

|

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.