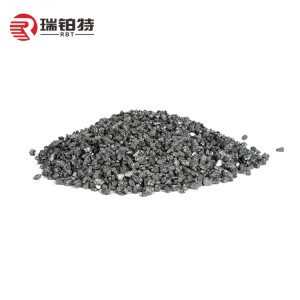

Green Silicon Carbide Grit

description

Green silicon carbide is produced by smelting petroleum coke and high-quality silica in an electric resistance furnace at high temperature. The refined crystal has high purity, high hardness, hardness between corundum and diamond, and mechanical strength is higher than corundum.The SiC purity of green silicon carbide is up to 99%min.With high thermal conductivity and high strength which get no decrease in 1000 centigrade.

Application

1. Green silicon carbide segment sand: The particles are rounded and used as a grinding medium, perfectly replacing high priced zirconia balls. In the ultrafine powder grinding of green silicon carbide photovoltaic blade materials, it has a perfect grinding effect without affecting product content.

2. Green silicon carbide grit sand: mainly used as sandblasting medium for grinding tool manufacturing and surface treatment. Abrasive tool manufacturing: resin grinding wheel, ultra-thin cutting disc, marble grinding wheel, diamond grinding disc and other surface treatment: grinding hard alloy, hard brittle metal and non-metallic materials quartz glass, optical glass, piezoelectric ceramics and so on.

3. Green silicon carbide micropowder: can be used for precision grinding of hard glass, slicing of monocrystalline silicon and polycrystalline silicon rods, precision grinding of monocrystalline silicon wafers, processing of superhard metals, processing of soft metals such as copper and copper alloys, and processing of various resin materials.

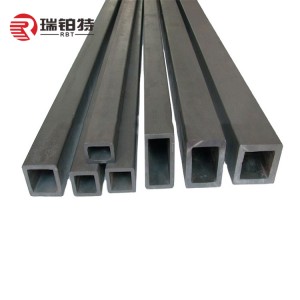

4.Refractory,Furnace Burden,Castable,Ramming Compoynd,Refractory Bricks etc

5.Used to produce Polishing wax,polishing fluid,grinding powder,grinding fluid and so on

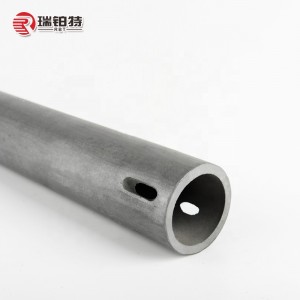

6.It is an ideal material for wear-resistant pipelines and ore bucket lining.

7.Mainly used as wear-resistant and corrosion-resistant materials, it can also be made into rocket nozzles, gas turbine blades, etc.

8.Thin plate kiln furniture can be manufactured by utilizing its thermal conductivity, thermal radiation, and high thermal intensity.

9.Used for making grinding wheels, sandpaper, abrasive belts, oilstones, grinding blocks, grinding heads, grinding paste, etc.

10.Its wear resistance is 5-20 times longer than the service life of cast iron and rubber, and it is also one of the ideal materials for aviation flight runways.

11.Used for wire cutting of potassium arsenide and quartz crystals. It is an engineering processing material for the solar photovoltaic industry, semiconductor industry, and piezoelectric crystal industry.

12.Green silicon carbide can be used for consolidation and coating abrasives, free grinding and polishing, etc. Coating of various non-ferrous metal objects.

13.Brake linings.

Product Specification

| CHEMICAL CONTENT | |

| SiC | 98% min |

| SiO2 | 1% max |

| H2O3 | 0.5% max |

| Fe2O3 | 0.4% max |

| F.C | 0.4% max |

| Magnetic Material | 0.02% max |

| PHYSICAL PROPERTIES | |

| Moh's Hardness | 9.2 |

| Melting Point | 2300℃ |

| Working Temperature | 1900℃ |

| Specific Gravity | 3.2-3.45 g/cm3 |

| Bulk Density | 1.2-1.6 g/cm3 |

| Color | Black |

| Elasticity Modulus | 58-65x106psi |

| Coefficient of Thermal Expansion | 3.9-4.5 x10-6/℃ |

| Thermal Conductivity | 71-130 W/m.K |

| Grain Size | |

| 0-1mm,1-3 mm, 3-5mm, 5-8mm, 6/10, 10/18, 200-0mesh, 325mesh, 320mesh, 400mesh, 600mesh, 800mesh, 1000mesh, #24, #36, #46, #60, #80, #100, #120, #180, #220, #240...Other special spec. could be supplied as required. | |