High Alumina Refractory Bricks

High-alumina refractory bricks are a type of aluminosilicate refractory material with alumina as the main component. With an alumina content exceeding 48%, they are classified as neutral refractory materials, made from bauxite or other raw materials with high alumina content through molding and calcination.

Classification:

Based on the alumina content, they are divided into three grades:

Grade 1: high-alumina bricks (Al₂O₃ content > 75%)

Grade 2: high-alumina bricks (Al₂O₃ content: 60%~75%)

Grade 3: high-alumina bricks (Al₂O₃ content: 48%~60%)

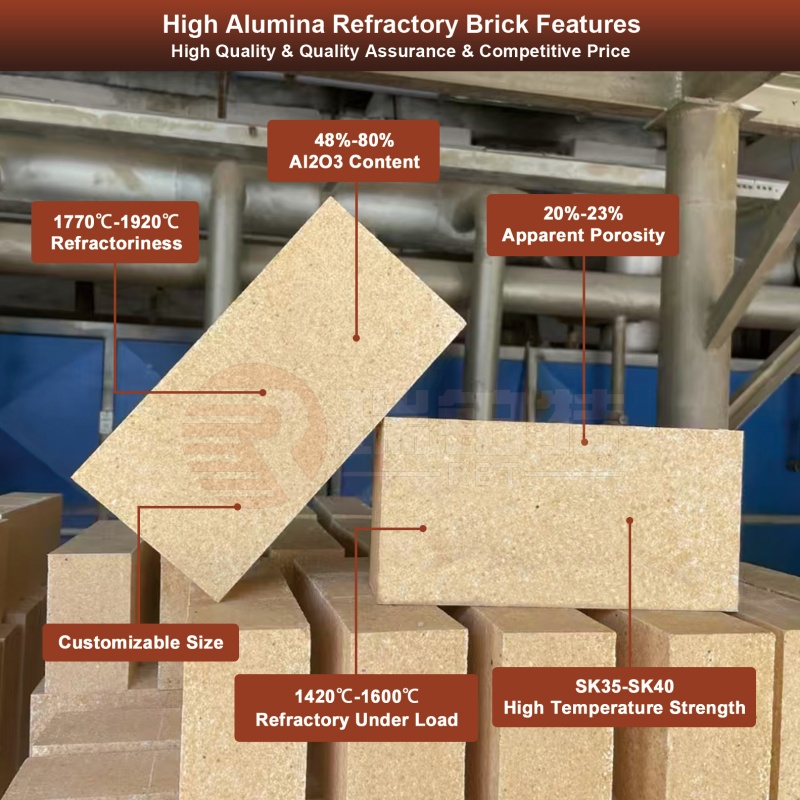

Production Process:

The production process of high-alumina bricks is similar to that of multi-clinker fire clay bricks. The proportion of clinker in the mix can be as high as 90%~95%. Before crushing, the clinker needs to be graded, sorted and sieved for iron removal. The firing temperature is relatively high; Grade 1 and Grade 2 high-alumina bricks are generally fired at 1500℃~1600℃ in tunnel kilns.

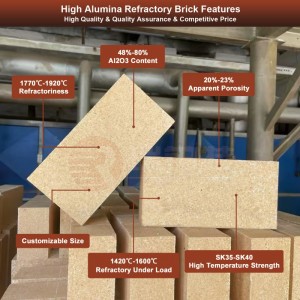

Physicochemical Properties:

1. Refractoriness

It can withstand high temperatures above 1770℃, generally ranging from 1750℃ to 1790℃. The refractoriness increases with the rise of alumina content.

2. Load Softening Temperature

It is generally 1420℃~1530℃. Owing to the high alumina content, low impurity content and minimal formation of fusible glass phase, its load softening temperature is higher than that of fire clay bricks.

3. Cold Compressive Strength

The cold compressive strength of Grade 1 high-alumina bricks (LZ-80) is ≥ 70 MPa, while that of Grade 3 high-alumina bricks (LZ-48) is ≥ 40 MPa.

4. Slag Resistance

High-alumina bricks are close to neutral refractory materials, which can resist the erosion of both acidic and alkaline slags, but their resistance to alkaline slags is weaker than that to acidic slags.

5. Apparent Porosity

The apparent porosity of Grade 1 high-alumina bricks is ≤ 21%, and that of Grade 3 high-alumina bricks is ≤ 22%.

|

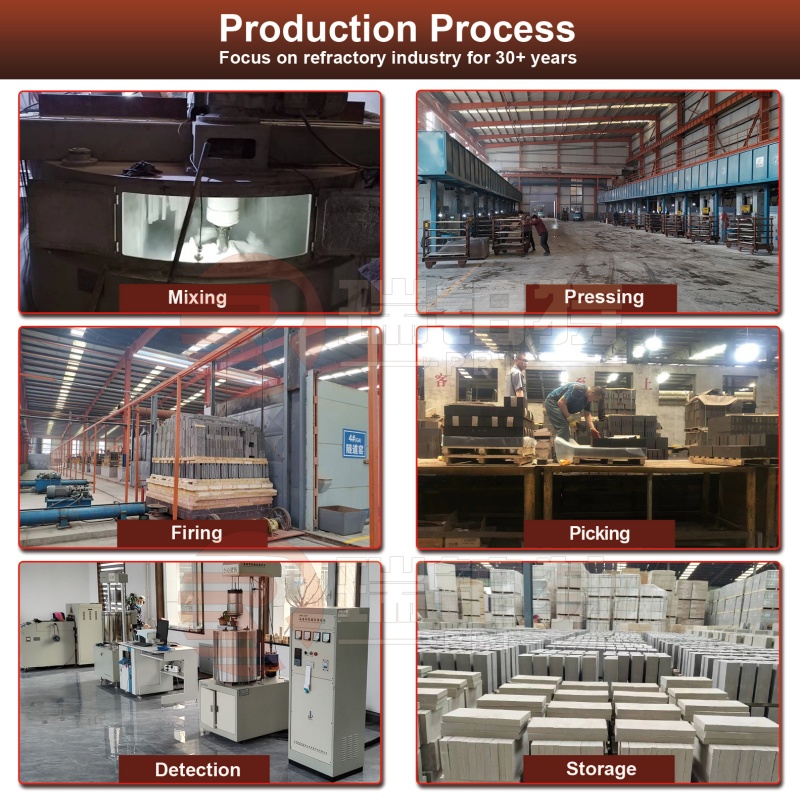

INDEX

|

SK-35

|

SK-36

|

SK-37

|

SK-38

|

SK-39

|

SK-40

|

|

Refractoriness(℃) ≥

|

1770

|

1790

|

1820

|

1850

|

1880

|

1920

|

|

Bulk Density(g/cm3) ≥

|

2.25

|

2.30

|

2.35

|

2.40

|

2.45

|

2.55

|

|

Apparent Porosity(%) ≤

|

23

|

23

|

22

|

22

|

21

|

20

|

|

Cold Crushing Strength(MPa) ≥

|

40

|

45

|

50

|

55

|

60

|

70

|

|

Permanent Linear Change@1400°×2h(%)

|

±0.3

|

±0.3

|

±0.3

|

±0.3

|

±0.2

|

±0.2

|

|

Refractoriness Under Load @ 0.2MPa(℃) ≥

|

1420

|

1450

|

1480

|

1520

|

1550

|

1600

|

|

Al2O3(%) ≥

|

48

|

55

|

62

|

70

|

75

|

80

|

|

Fe2O3(%) ≤

|

2.0

|

2.0

|

2.0

|

2.0

|

2.0

|

1.8

|

High alumina bricks are mainly used for VOD, AOD, blast furnaces, hot blast furnaces, EAF, reverberatory furnaces, and rotary kiln linings. In addition, high alumina bricks are also widely used as open-hearth heat storage checker bricks, plugs for pouring systems, nozzle bricks, etc.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.