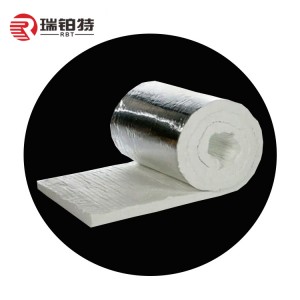

High-Quality Fiber Shaped Parts for Insulation

description

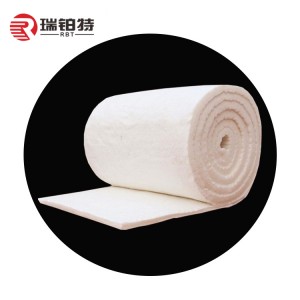

Using high quality aluminum silicate fiber cotton as raw material, vacuum molding process. It can be made into different bulk density of 200-400kg/m3, different shapes of bricks, boards, modules, standard prefabricated parts, burners, drums and other special products to meet the needs of certain industrial sectors in specific production links, and its shape and size need to make special abrasive tools. All abnormity products have low shrinkage over their service temperature range and maintain high thermal insulation, light weight and impact resistance. Unburned material can easily be cut or machined. In the process of using, the product has good anti-wear and anti-spalling properties, and is not eroded by most molten metals.

Features

Product features: large proportion of fiber, light weight, high strength, low thermal conductivity, thermal shock resistance, easy machining, airflow erosion resistance, easy required to control the density, a certain compression, tensile, flexural strength, complex shape plasticity.

Application

Products are used in various industries of thermal equipment heat surface lining materials, backing and heat insulation, insulation material of high temperature industrial furnace wall masonry, roof hanging, anchor and oven door, kiln car, petroleum chemical industry with burner, observation hole components, groove, groove pad, small mouth and tundish, riser sleeve assembly for metal melting, insulation engineering with any complex geometry suite.

Product Index

| INDEX \PRODUCT | STD | HC | HA | HZ |

| Classification Temperature(℃) | 1260 | 1260 | 1360 | 1430 |

| Working Temperature(℃)≤ | 1050 | 1100 | 1200 | 1350 |

| Bulk Density(kg/m3) | 200~400 | |||

| Thermal Conductivity(W/m.k) | 0.086(400℃) 0.120(800℃) |

0.086(400℃) 0.110(800℃) |

0.092(400℃) 0.186(1000℃) |

0.092(400℃) 0.186(1000℃) |

| Permanent Linear Change(%) | -4/1000℃ | -3/1100℃ | -3/1200℃ | -3/1350℃ |

| Modulus of Rupture(MPa) | 6 | |||

| Al2O3(%) ≥ | 45 | 47 | 55 | 39 |

| Fe2O3(%) ≤ | 1.0 | 0.2 | 0.2 | 0.2 |

| SiO2(%) ≤ | 52 | 52 | 49 | 45 |

| ZrO2(%) ≥ | 11~13 | |||