Magnesia Refractory Bricks

Magnesia refractory bricks are alkaline refractory materials with high‑purity magnesium oxide (MgO) as the main component (typically ≥85%) and periclase (MgO) as the primary crystalline phase. They offer core advantages such as high refractoriness and strong resistance to alkaline slag erosion, and are widely used in high‑temperature industrial applications such as metallurgy and building materials. Their main limitation is relatively poor thermal shock resistance.

Classification:

Sintered Magnesia Bricks:

MgO content ranges from 91% to 96.5%. Common grades are referred to as 92 Magnesia Brick, 95 Magnesia Brick, and 97 Magnesia Brick.

Commonly used grades (marks): MG, MZ.

Fused Magnesia Bricks:

MgO content ranges from 95.5% to 98.2%. Common grades are referred to as Fused 95 Magnesia Brick, Fused 97 Magnesia Brick, and Fused 98 Magnesia Brick.

Commonly used grades (marks): DM, MZ.

Refractoriness—Magnesium bricks have very high refractoriness, generally exceeding 2000°C.

Load softening temperature—The load softening onset temperature of magnesia bricks is much lower than their refractoriness, approximately 1530~1580°C.

Magnesium bricks have good thermal conductivity—Magnesium bricks have a thermal conductivity several times that of clay bricks, and their thermal conductivity decreases with increasing temperature.

Magnesium bricks have poor thermal shock resistance—They can only withstand 2~3 water cooling cycles. This is because of their high coefficient of thermal expansion and poor thermal conductivity, making them prone to generating significant thermal stress during rapid temperature changes.

Slag resistance and hydration resistance—Magnesium bricks are alkali-resistant but not acid-resistant. The formation of magnesium ferrite and calcium magnesium olivine reduces their resistance to hydration. Therefore, waterproofing and moisture protection are essential under all circumstances.

|

INDEX

|

MG-91

|

MG-95A

|

MG-95B

|

MG-97A

|

MG-97B

|

MG-98

|

|

Bulk Density(g/cm3) ≥

|

2.90

|

2.95

|

2.95

|

3.00

|

3.00

|

3.00

|

|

Apparent Porosity(%) ≤

|

18

|

17

|

18

|

17

|

17

|

17

|

|

Cold Crushing Strength(MPa) ≥

|

60

|

60

|

60

|

60

|

60

|

60

|

|

Refractoriness Under Load @0.2MPa(℃) ≥

|

1580

|

1650

|

1620

|

1700

|

1680

|

1700

|

|

MgO(%) ≥

|

91

|

95

|

94.5

|

97

|

96.5

|

97.5

|

|

SiO2(%) ≤

|

4.0

|

2.0

|

2.5

|

1.2

|

1.5

|

0.6

|

|

CaO(%) ≤

|

3 |

2.0

|

2.0

|

1.5

|

2.0

|

1.0

|

Iron and Steel Industry:

Used in BOFs (Basic Oxygen Furnaces), EAFs (Electric Arc Furnaces), and ladle linings, as well as mixers and ferroalloy furnaces. It resists erosion from molten steel and alkaline slags.

Building Materials Industry:

Used in the burning zone and transition zone of cement rotary kilns, and as linings for lime kilns. It withstands alkali corrosion from clinker and high-temperature scouring.

Non-ferrous Metallurgy:

Used as linings for smelting furnaces and refining furnaces for copper, nickel, etc. It is suitable for high-temperature conditions and corrosion from molten non-ferrous metals.

Other Applications:

Used as linings for ultra-high temperature equipment such as glass furnace regenerators, chemical high-temperature reactors, and waste incinerators.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

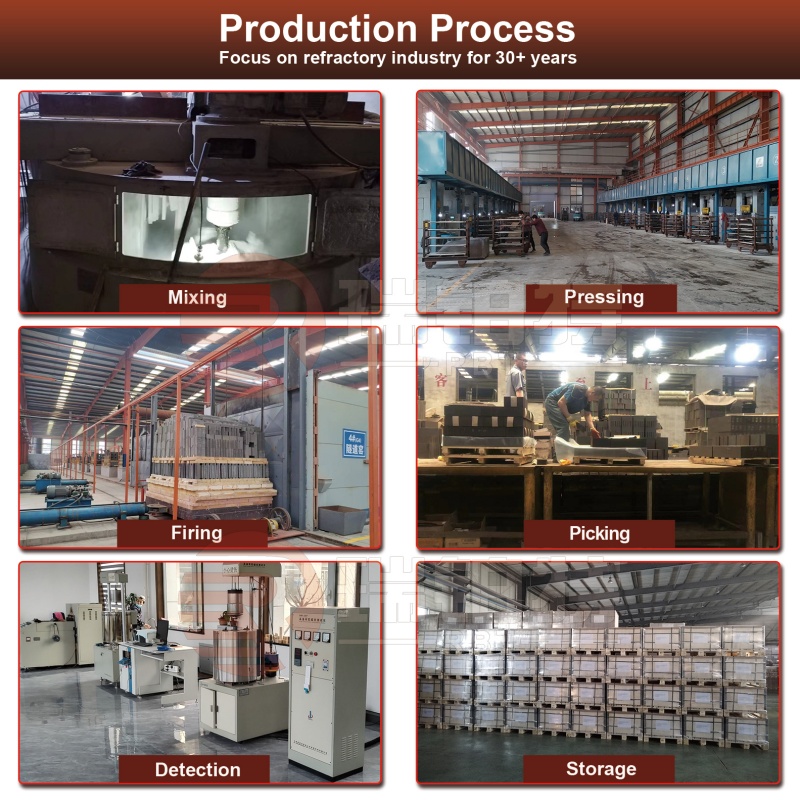

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.