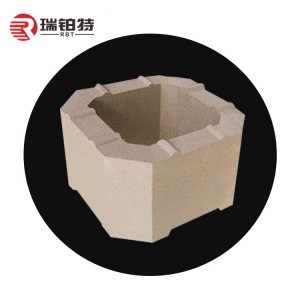

Magnesia Aluminum Bricks

description

Magnesia-alumina brick: Magnesia alumina spinel brick is an alkaline refractory with periclase and spinel as the main minerals, which is formed by high-pressure molding and high temperature sintering. At the same time, specific mineralizer is added to directly combine the crystal phase particles of the product.

Features

It is characterized by high temperature chemical corrosion resistance, excellent alkali resistance, high load softening temperature, good thermal shock stability, strong erosion resistance, and good high temperature service performance.

Application

It is mainly used in the upper and lower transition zone of cement rotary kiln and the kiln equipment that requires high temperature resistance and heat shock resistance.

Product Index

|

INDEX |

MgO (%)≥ |

Al2O3 (%)≥ |

SiO2 (%)≥ |

Fe2O3 (%)≤ |

Apparent Porosity(%)≤ |

Bulk Density(g/cm3)≥ |

Cold Crushing Strength(MPa)≥ |

Refractoriness Under Load(℃) 0.2MPa ≥ |

|

RBTMA-82 |

82 |

9-13 |

2.0 |

--- |

18 |

2.90 |

50 |

1700 |

|

RBTMA-85 |

85 |

9-13 |

1.5 |

--- |

18 |

2.95 |

50 |

1700 |

|

RBTMTA-80 |

80 |

3.0 |

2.0 |

7.5 |

18 |

2.90 |

45 |

1600 |

|

RBTMTA-85 |

85 |

2.5 |

1.5 |

7.5 |

17 |

3.00 |

50 |

1650 |

| RBTMTA-90 |

90 |

4.0 |

1.5 |

4.5 |

17 |

2.85 |

50 |

1650 |

|

RBTMTA-92 |

92 |

3.5 |

1.5 |

4.0 |

17 |

2.95 |

55 |

1700 |