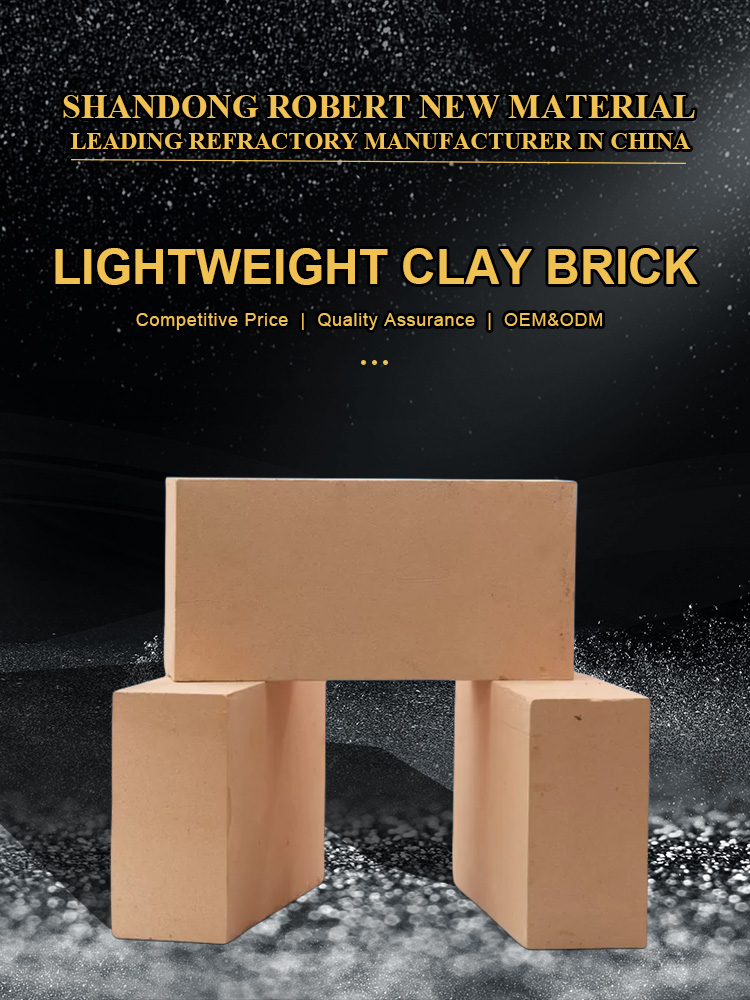

Manufacturing Companies for Lightweight Refractory Fireclay Insulation Bricks for Furnace

Innovation, top quality and reliability are the core values of our company. These principles today extra than ever form the basis of our success as an internationally active mid-size company for Manufacturing Companies for Lightweight Refractory Fireclay Insulation Bricks for Furnace, Since establishment during the early 1990s, now we have setup our sale network in USA, Germany, Asia, and several Middle Eastern countries. We purpose to generally be a top class supplier for worldwide OEM and aftermarket!

Innovation, top quality and reliability are the core values of our company. These principles today extra than ever form the basis of our success as an internationally active mid-size company for China Insulation Bricks and Thermal Insulation Bricks, Our company promises: reasonable prices, short production time and satisfactory after-sales service, we also welcome you to visit our factory at any time you want. Wish we’ve got a pleasant and long terms business together!!!

Product Information

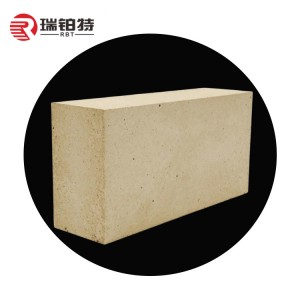

| Product Name | Insulation Lightweight Clay Bricks |

| Description | Insulation fireclay bricks are a kind of high temperature insulation refractory material. It is made of refractory clay clinker as raw material, plastic clay as binder, adding an appropriate amount of combustible or foaming agent, pressed brick press molding, and then sintered. |

| Model | RBT-0.6/0.8/1.0/1.2 |

| Size | Standard Size: 230 x 114 x 65 mm, special size and OEM service also provide! |

| Features | High strength, good thermal shock resistance, small change of permanent linear, small thermal conductivity, good insulation performance. |

Details Images

Product Index

| INDEX | RBT-0.6 | RBT-0.8 | RBT-1.0 | RBT-1.2 |

| Bulk Density(g/cm3) ≥ | 0.6 | 0.8 | 1.0 | 1.2 |

| Cold Crushing Strength(MPa) ≥ | 2 | 3 | 3.5 | 5 |

| Permanent Linear Change℃×12h ≤2% | 900 | 900 | 900 | 1000 |

| Thermal Conductivity350±25℃ (W/m.k) | 0.25 | 0.35 | 0.40 | 0.50 |

| Al2O3(%) ≥ | 35 | 35 | 35 | 35 |

| Fe2O3(%) ≤ | 2.0 | 2.0 | 2.0 | 2.0 |

Application

Widely used in metallurgy, machinery, ceramics, chemical and other thermal equipment

and industrial furnace lining and layer.

Package&Warehouse

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

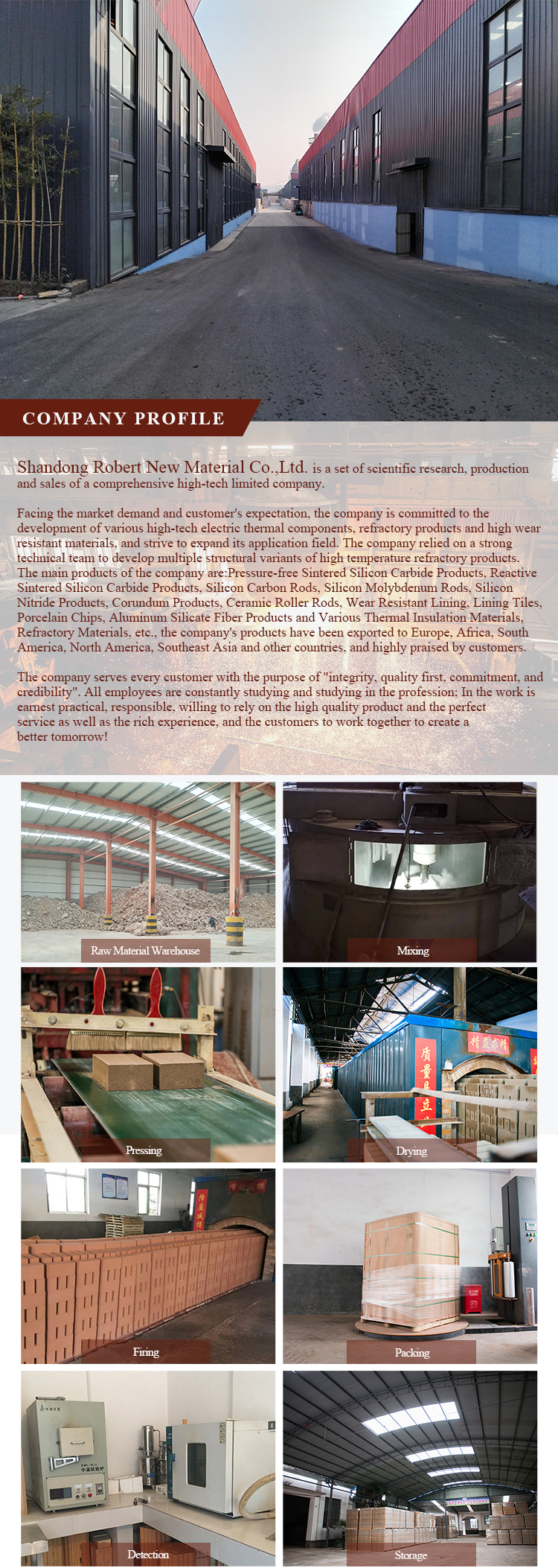

Are you a manufacturer or a trader?

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

How do you control your quality?

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

What is your delivery time?

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Do you provide free samples?

Of course, we provide free samples.

Can we visit your company?

Yes, of course, you are welcome to visit RBT company and our products.

What is the MOQ for trial order?

There is no limit, we can provide the best suggestion and solution according to your situation.

Why choose us?

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.

Innovation, top quality and reliability are the core values of our company. These principles today extra than ever form the basis of our success as an internationally active mid-size company for Manufacturing Companies for Lightweight Refractory Fireclay Insulation Bricks for Furnace, Since establishment during the early 1990s, now we have setup our sale network in USA, Germany, Asia, and several Middle Eastern countries. We purpose to generally be a top class supplier for worldwide OEM and aftermarket!

Manufacturing Companies for China Insulation Bricks and Thermal Insulation Bricks, Our company promises: reasonable prices, short production time and satisfactory after-sales service, we also welcome you to visit our factory at any time you want. Wish we’ve got a pleasant and long terms business together!!!