Mullite Bricks

About Mullite Bricks

Mullite bricks are a high aluminum refractory with mullite as the main crystal phase. Generally, the content of alumina is between 65% and 75%. In addition to mullite, the minerals with lower alumina content also contain a small amount of vitreous phase and cristobalite. The higher alumina content also contains a small amount of corundum.

Mullite bricks have a high refractoriness, which can reach above 1790 °C. Load softening start temperature is 1600~1700℃. The compressive strength at room temperature is 70-260MPa. Good thermal shock resistance.

There are two types of sintered mullite bricks and fused mullite bricks.

Sintered mullite bricks are made of high-alumina bauxite clinker as the main raw material, adding a small amount of clay or raw bauxite as a binder, and are formed and fired. Fused mullite bricks are made of high bauxite, industrial alumina and refractory clay, and charcoal or coke fine particles are added as a reducing agent. After molding, they are manufactured by reducing electrofusion.

The crystallization of fused mullite is larger than that of sintered mullite, and its thermal shock resistance is better than that of sintered products. Their high temperature performance mainly depends on the content of alumina and the uniformity of distribution of mullite phase and glass.

Mullite bricks are mainly used for hot blast stove top, blast furnace body and bottom, glass furnace regenerator, ceramic kiln, dead corner lining of petroleum cracking system, etc.

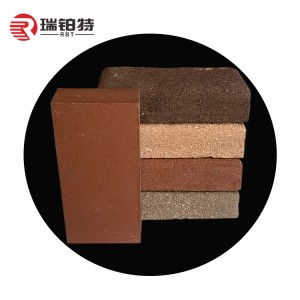

About Sillimanite

The sillimanite bricks have good thermal stability at high temperature, resistance to glass liquid erosion, small pollution to glass liquid.

Mostly suitable for feeding channel, feeding machine, tube pulling machine and other equipment in glass industry, which can significantly improve productivity.

Mostly suitable for feeding channel, feeding machine, tube pulling machine and other equipment in glass industry, which can significantly improve productivity.

Product Index

|

INDEX |

Triple low mullite |

Sintered mullite |

Sillimanite |

Fused mullite |

||||

|

RBTM-47 |

RBTM-65 |

RBTM-70 |

RBT-M75 |

RBTM-80 |

RBTA-60 |

RBTFM-75 |

||

|

Refractoriness(℃) ≥ |

1790 |

1790 |

1790 |

1790 |

1810 |

1790 |

1810 |

|

|

Bulk Density(g/cm3) ≥ |

2.42 |

2.45 |

2.50 |

2.60 |

2.70 |

2.48 |

2.70 |

|

|

Apparent Porosity(%) ≤ |

12 |

18 |

18 |

17 |

17 |

18 |

16 |

|

|

Cold Crushing Strength(MPa) ≥ |

60 |

60 |

70 |

80 |

85 |

65 |

90 |

|

|

Permanent Linear Change(%) |

1400°×2h |

+0.1 -0.1 |

|

|

|

|

|

|

|

1500°×2h |

|

+0.1 -0.4 |

+0.1 -0.4 |

+0.1 -0.4 |

+0.1 -0.4 |

+1 -0.2 |

±0.1 |

|

|

Refractoriness Under Load @0.2MPa (℃)≥ |

1520 |

1580 |

1600 |

1600 |

1620 |

1600 |

1700 |

|

|

Creep Rate @0.2MPa 1200°×2h(%) ≤ |

0.1 |

― |

― |

― |

― |

― |

― |

|

|

Al2O3(%) ≥ |

47 |

64 |

68 |

72 |

78 |

60 |

75 |

|

|

Fe2O3(%) ≤ |

1.2 |

0.8 |

0.8 |

0.7 |

0.7 |

1.0 |

0.5 |

|