The general requirements for refractory materials for electric arc furnaces are:

(1) The refractoriness should be high. The arc temperature exceeds 4000°C, and the steelmaking temperature is 1500~1750°C, sometimes as high as 2000°C, so refractory materials are required to have high refractoriness.

(2) The softening temperature under load should be high. The electric furnace works under high temperature load conditions, and the furnace body has to withstand the erosion of molten steel, so the refractory material is required to have a high load softening temperature.

(3) The compressive strength should be high. The electric furnace lining is affected by the impact of the charge during charging, the static pressure of molten steel during smelting, the erosion of steel flow during tapping, and mechanical vibration during operation. Therefore, the refractory material is required to have high compressive strength.

(4) The thermal conductivity should be small. In order to reduce the heat loss of the electric furnace and reduce the power consumption, the refractory material is required to have poor thermal conductivity, that is, the thermal conductivity coefficient should be small.

(5) Thermal stability should be good. Within a few minutes from tapping to charging in electric furnace steelmaking, the temperature drops sharply from around 1600°C to below 900°C, so refractory materials are required to have good thermal stability.

(6) Strong corrosion resistance. During the steelmaking process, slag, furnace gas and molten steel all have strong chemical erosion effects on refractory materials, so refractory materials are required to have good corrosion resistance.

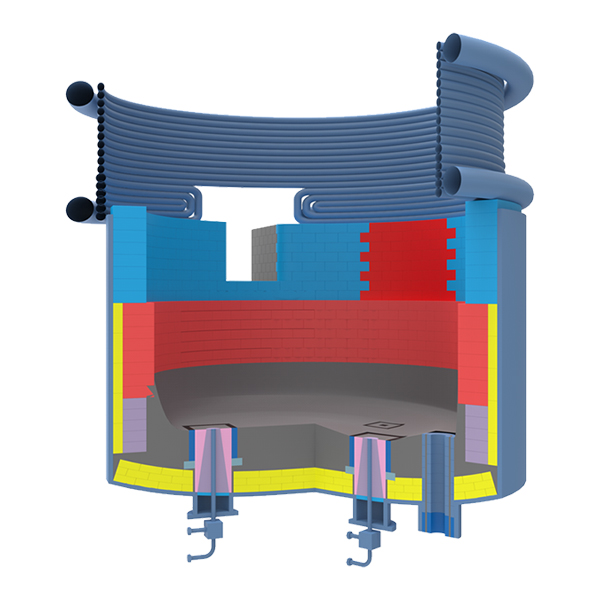

Selection of refractory materials for side walls

MgO-C bricks are usually used to build the side walls of electric furnaces without water-cooling walls. The hot spots and slag lines have the most severe service conditions. They are not only severely corroded and eroded by molten steel and slag, as well as severely mechanically impacted when scrap is added, but are also subject to thermal radiation from the arc. Therefore, these parts are constructed with MgO-C bricks with excellent performance.

For the side walls of electric furnaces with water-cooled walls, due to the use of water-cooling technology, the heat load is increased and the use conditions are more stringent. Therefore, MgO-C bricks with good slag resistance, thermal shock stability and high thermal conductivity should be selected. Their carbon content is 10%~20%.

Refractory materials for side walls of ultra-high power electric furnaces

The side walls of ultra-high power electric furnaces (UHP furnaces) are mostly built with MgO-C bricks, and the hot spots and slag line areas are built with MgO-C bricks with excellent performance (such as full carbon matrix MgO-C bricks). Significantly improve its service life.

Although the furnace wall load has been reduced due to improvements in electric furnace operating methods, it is still difficult for refractory materials to extend the service life of hot spots when operating under UHP furnace smelting conditions. Therefore, water cooling technology has been developed and applied. For electric furnaces using EBT tapping, the water cooling area reaches 70%, thus greatly reducing the use of refractory materials. Modern water cooling technology requires MgO-C bricks with good thermal conductivity. Asphalt, resin-bonded magnesia bricks and MgO-C bricks (carbon content 5%-25%) are used to build the side walls of the electric furnace. Under severe oxidation conditions, antioxidants are added.

For the hotspot areas most severely damaged by redox reactions, MgO-C bricks with large crystalline fused magnesite as raw material, carbon content greater than 20%, and full carbon matrix are used for construction.

The latest development of MgO-C bricks for UHP electric furnaces is to use high-temperature firing and then impregnation with asphalt to produce so-called fired asphalt-impregnated MgO-C bricks. As can be seen from Table 2, compared with unimpregnated bricks, the residual carbon content of fired MgO-C bricks after asphalt impregnation and recarbonization increases by about 1%, the porosity decreases by 1%, and the high-temperature flexural strength and pressure resistance are The strength has been significantly improved, so it has high durability.

Magnesium refractory materials for electric furnace side walls

Electric furnace linings are divided into alkaline and acidic. The former uses alkaline refractory materials (such as magnesia and MgO-CaO refractory materials) as the furnace lining, while the latter uses silica bricks, quartz sand, white mud, etc. to build the furnace lining.

Note: For furnace lining materials, alkaline electric furnaces use alkaline refractory materials, and acidic electric furnaces use acidic refractory materials.

Post time: Oct-12-2023