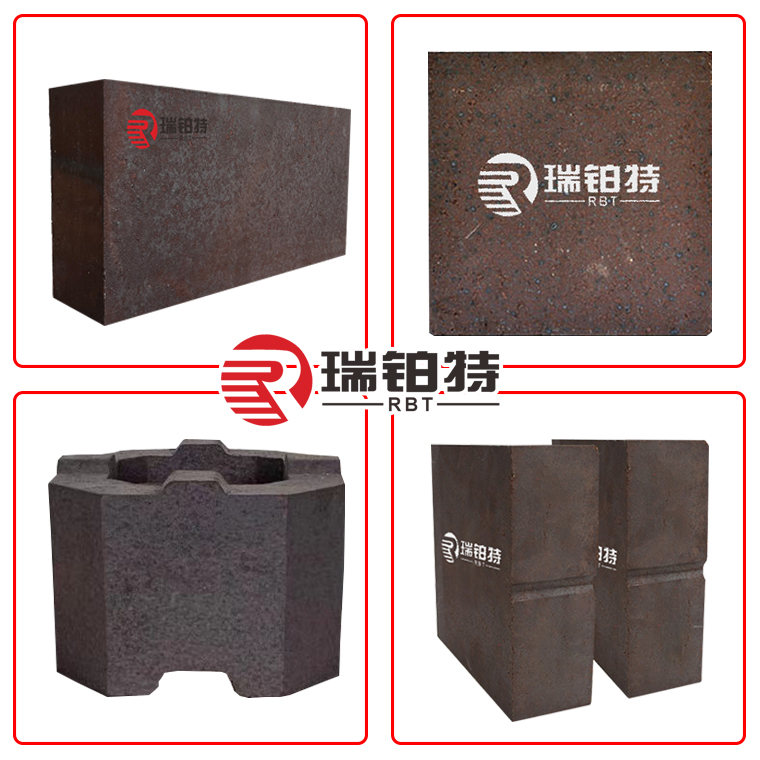

Magnesia-chrome brick is a basic refractory material with magnesium oxide (MgO) and chromium trioxide (Cr2O3) as the main components. It has excellent properties such as high refractoriness, thermal shock resistance, slag resistance and erosion resistance. Its main mineral components are periclase and spinel. These characteristics make magnesia-chrome bricks perform well in high temperature environments and are suitable for various high-temperature industrial equipment.

Ingredients and manufacturing process

The main raw materials of magnesia-chrome bricks are sintered magnesia and chromite. Magnesia has a high purity requirement, while the chemical composition of chromite is usually Cr2O3 content between 30% and 45%, and CaO content does not exceed 1.0% to 1.5%. The manufacturing process includes direct bonding method and non-firing method. Direct bonding magnesia-chrome bricks use high-purity raw materials and are fired at high temperature to form a high-temperature phase direct bonding of periclase and spinel, which significantly improves high-temperature strength and slag resistance.

Performance characteristics

High refractory: The refractoriness is usually above 2000°C, and it can maintain good structural stability at high temperature.

Thermal shock resistance: Due to the low thermal expansion coefficient, it can adapt to drastic changes in temperature.

Slag resistance: It has strong resistance to alkaline slag and certain acidic slag, and is particularly suitable for environments exposed to high-temperature slag.

Corrosion resistance: It has strong tolerance to acid-base alternating erosion and gas erosion.

Chemical stability: The solid solution formed by magnesium oxide and chromium oxide in magnesia-chrome bricks has high chemical stability.

Application fields

Magnesium-chrome bricks are widely used in the fields of metallurgical industry, cement industry and glass industry:

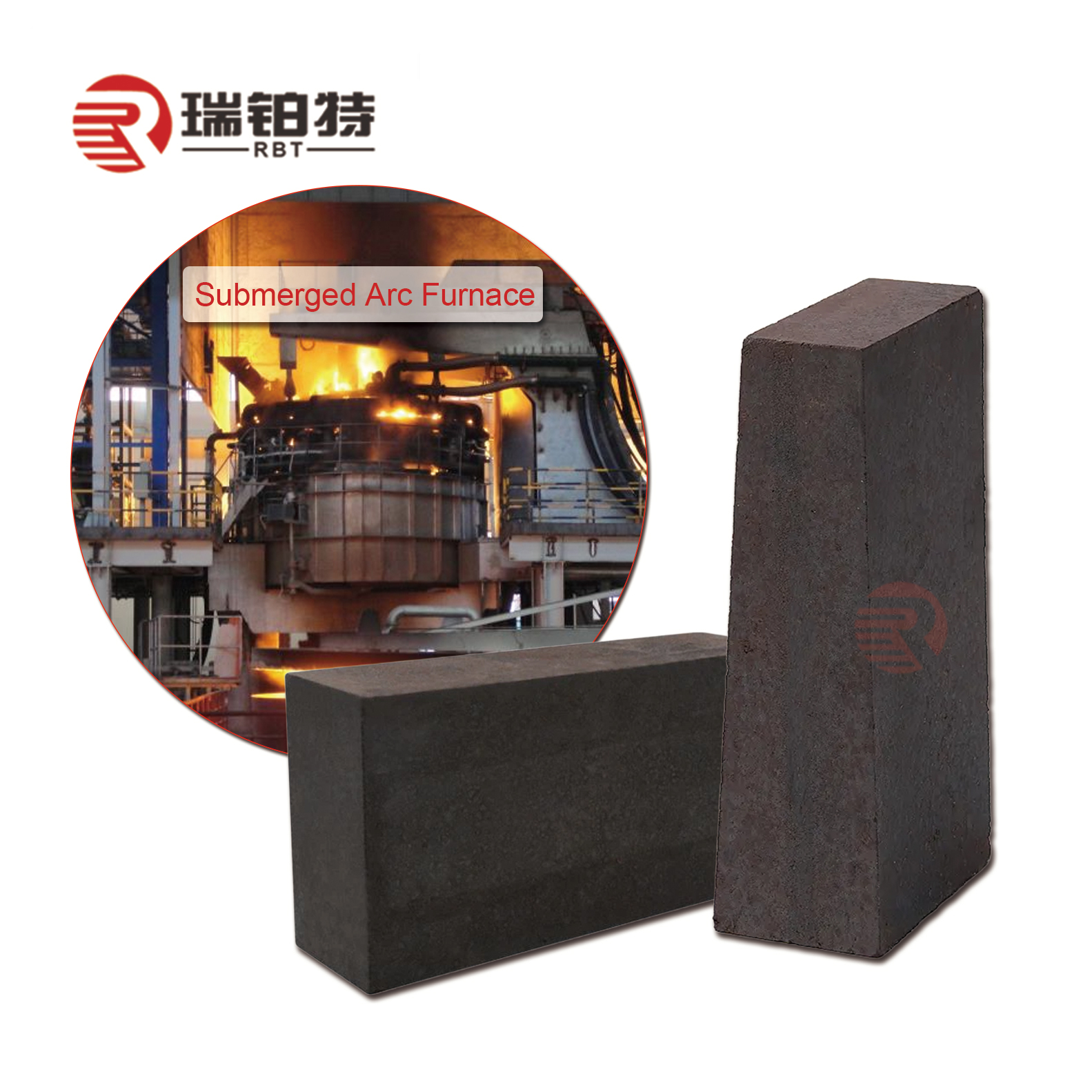

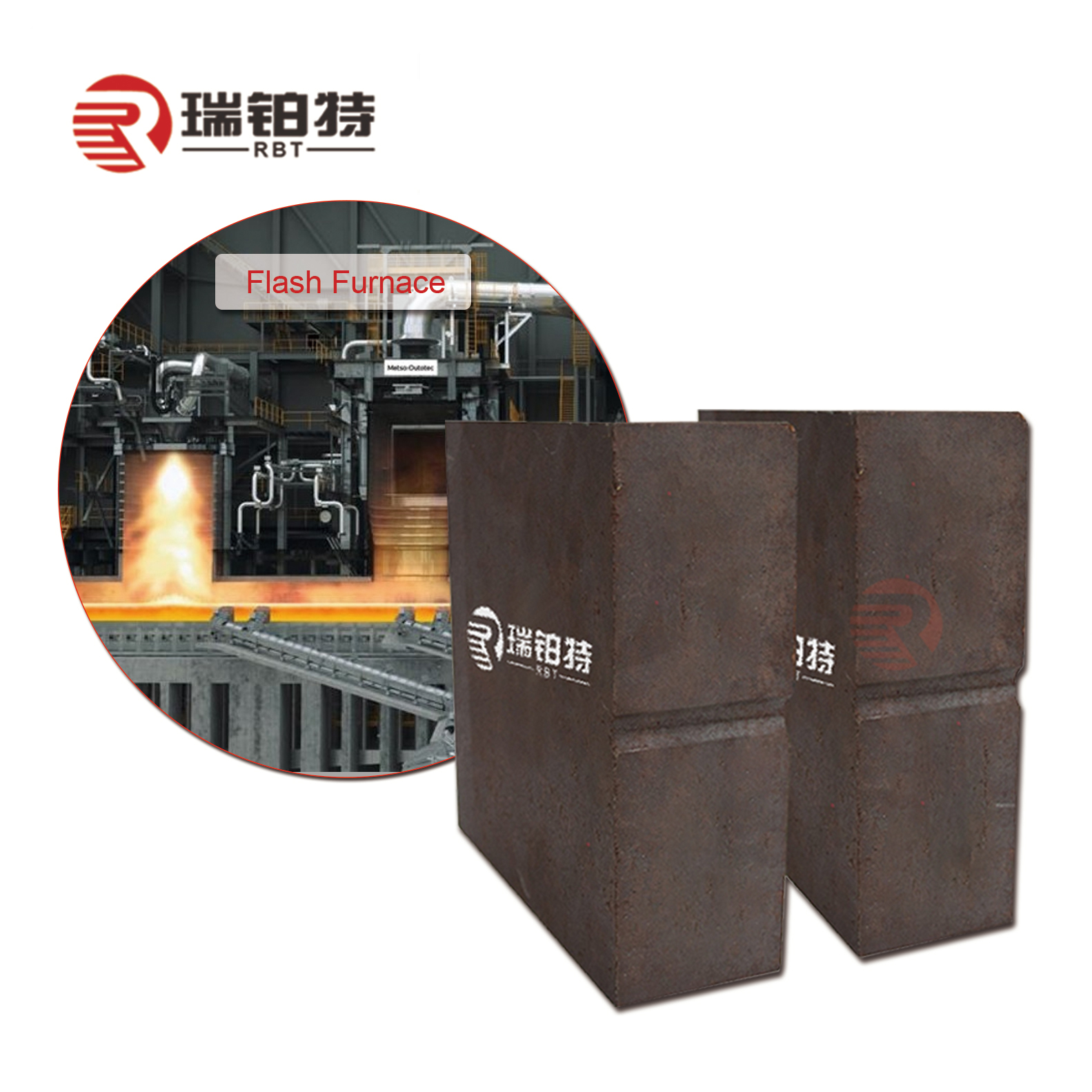

Metallurgical industry: used for the lining of high-temperature equipment such as converters, electric arc furnaces, open hearth furnaces, ladles and blast furnaces in the steel industry, especially suitable for the environment of handling high-temperature alkaline slag.

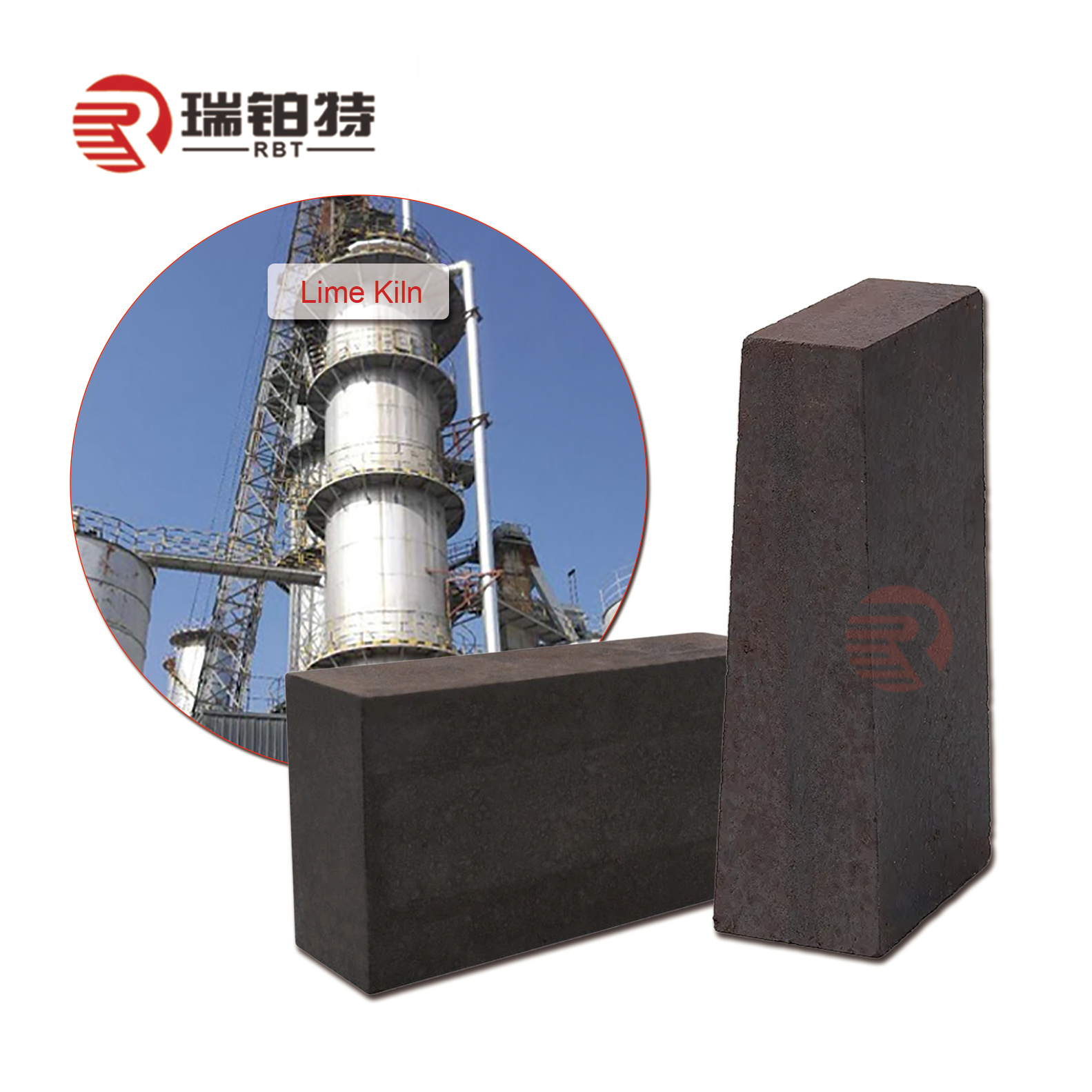

Cement industry: used for the firing zone and transition zone of cement rotary kilns to resist the erosion of high temperature and alkaline atmosphere.

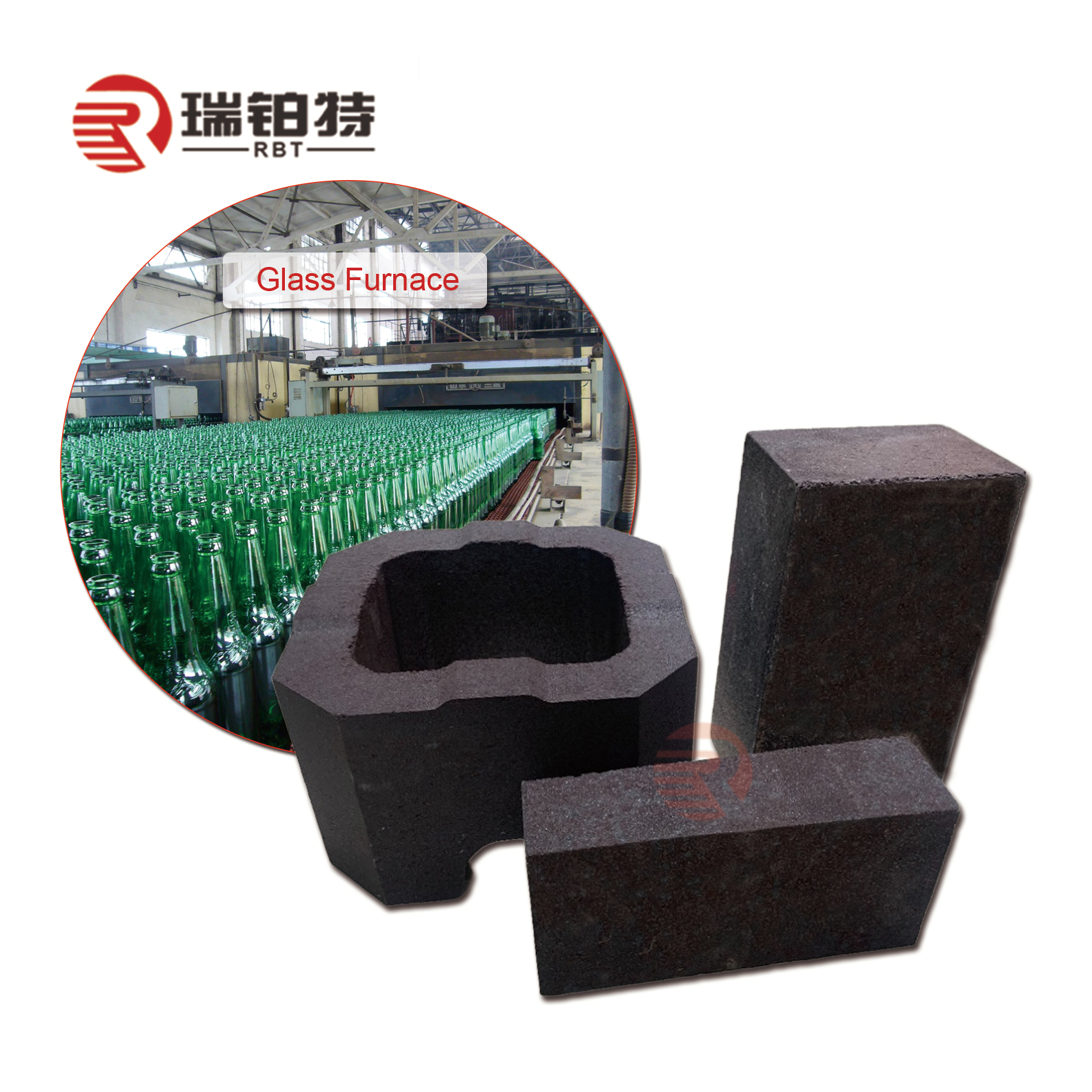

Glass industry: used for regenerators and upper structure parts in glass melting furnaces, and can withstand the erosion of high temperature atmosphere and alkaline glass liquid.

Post time: Jan-23-2025