Introduction to commonly used refractory materials for ladle

1. High alumina brick

Features: high alumina content, strong resistance to high temperature and corrosion.

Application: commonly used for ladle lining.

Precautions: avoid rapid cooling and heating to prevent thermal shock cracking.

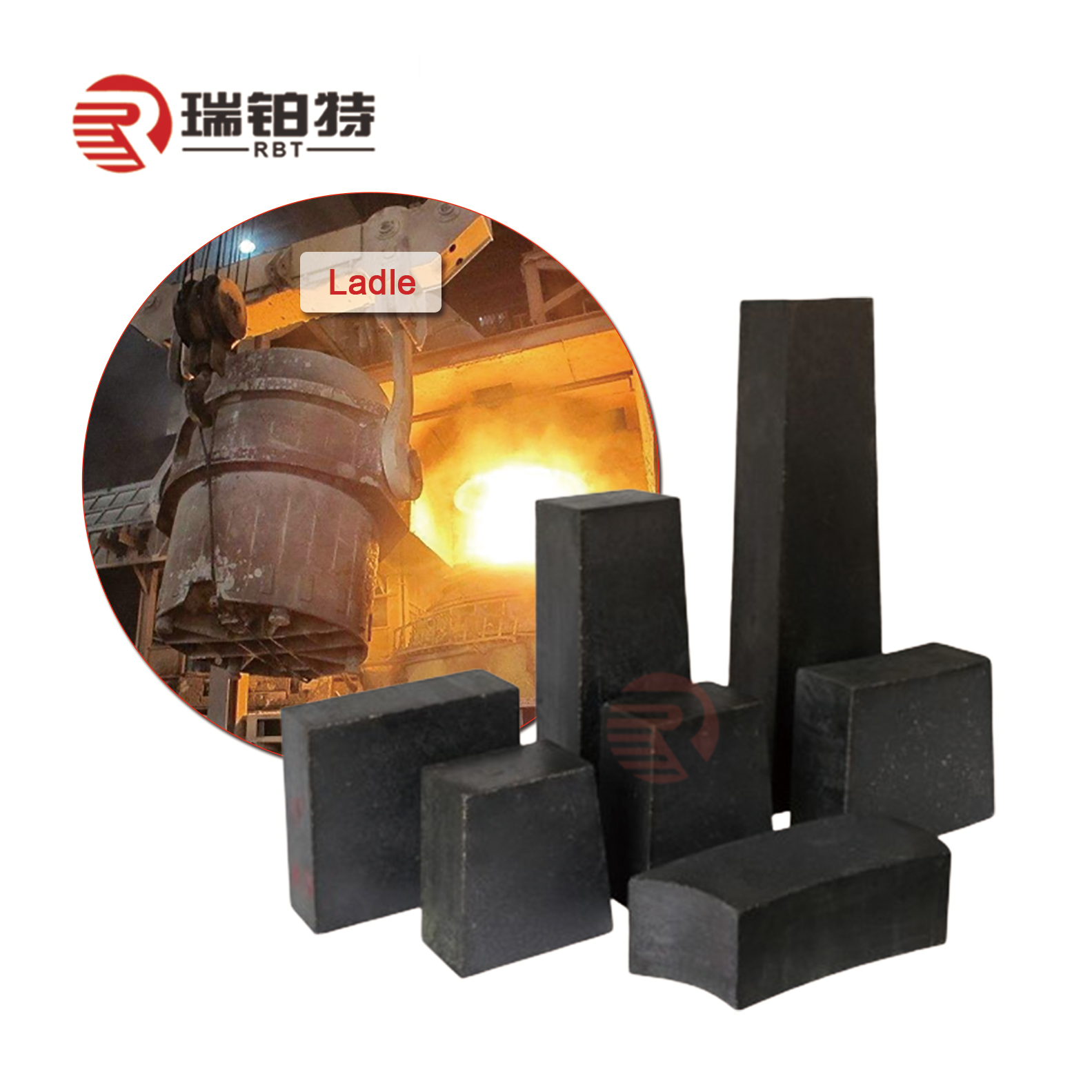

2. Magnesium carbon brick

Features: composed of magnesia sand and graphite, with good resistance to high temperature, corrosion and thermal shock.

Application: mostly used in slag line.

Precautions: prevent oxidation and avoid contact with oxygen at high temperature.

3. Aluminum magnesium carbon brick

Features: combines the advantages of high aluminum and magnesium carbon bricks, with excellent resistance to corrosion and thermal shock.

Application: suitable for ladle lining and slag line.

Precautions: avoid rapid cooling and heating to prevent thermal shock cracking.

4. Dolomite brick

Features: the main components are calcium oxide and magnesium oxide, resistant to high temperature and alkaline slag corrosion.

Application: commonly used in the bottom and side walls of the ladle.

Precautions: prevent moisture absorption and avoid storage in a humid environment.

5. Zircon bricks

Features: High temperature resistance and strong erosion resistance.

Application: Suitable for high temperature and severe erosion areas.

Notes: Avoid rapid cooling and heating to prevent thermal shock cracking.

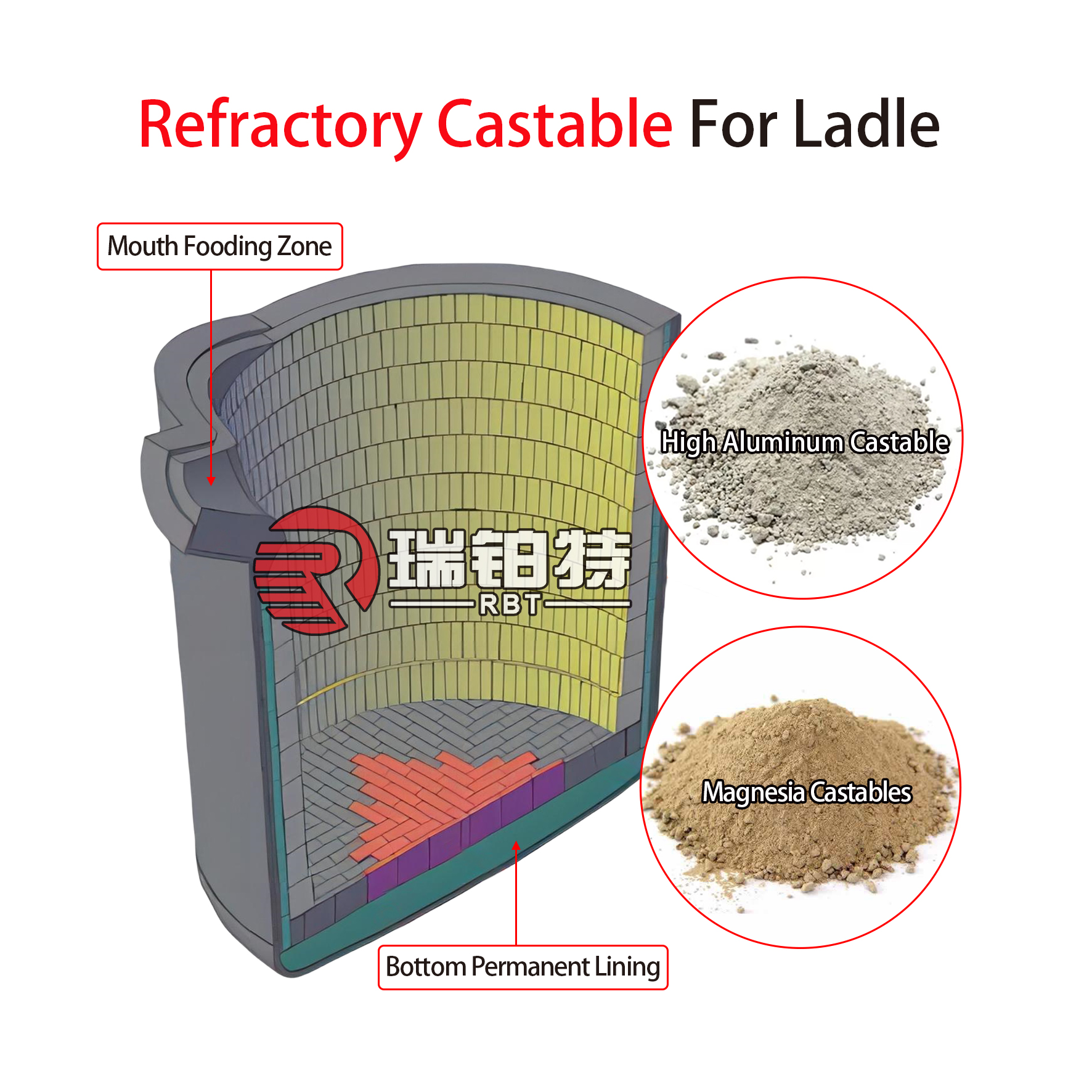

6. Refractory Castable

Features: Made of high aluminum, corundum, magnesia, etc., easy construction and good integrity.

Application: Commonly used for ladle lining and repair.

Notes: Pay attention to stirring evenly during construction to avoid bubbles and cracks.

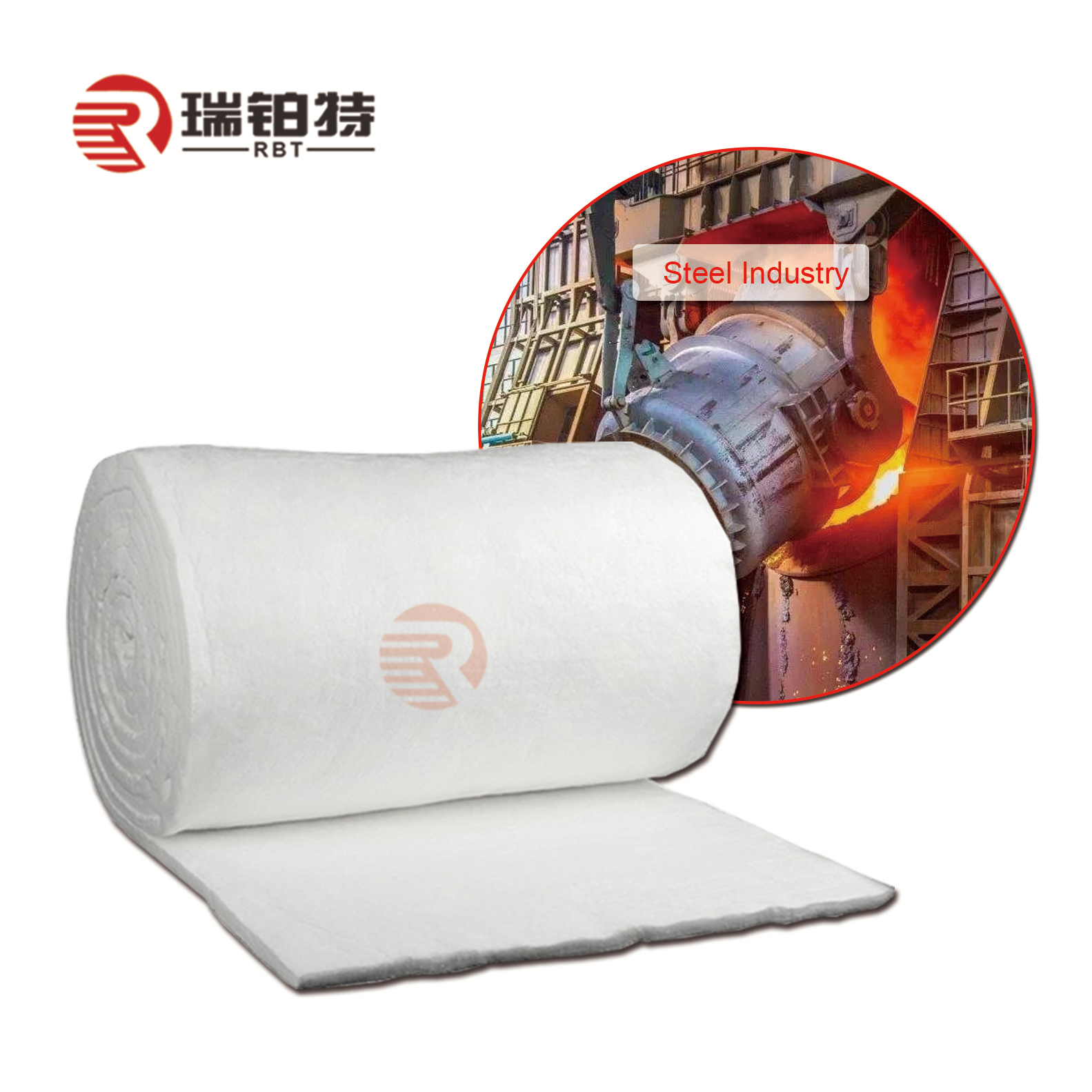

7. Insulation materials

Features: Such as lightweight insulation bricks and ceramic fibers to reduce heat loss.

Application: Used for ladle shells.

Notes: Avoid mechanical damage to prevent the insulation effect from decreasing.

8. Other refractory materials

Features: Such as corundum bricks, spinel bricks, etc., used according to specific needs.

Application: Use according to specific needs.

Notes: Use and maintain according to specific material characteristics.

Notes

Material selection: Select appropriate refractory materials according to the use conditions and process requirements of the ladle.

Construction quality: Ensure construction quality and avoid defects such as bubbles and cracks.

Use environment: Avoid rapid cooling and heating to prevent thermal shock cracking.

Storage conditions: Prevent refractory materials from absorbing moisture or oxidation, keep dry and ventilated.

Regular inspection: Regularly check the use of refractory materials and repair or replace damaged parts in time.

Operation specifications: Use the ladle strictly in accordance with the operating procedures to avoid overheating or overloading.

By rationally selecting and using refractory materials, the service life of the ladle can be effectively extended and production efficiency can be improved.

Post time: Feb-27-2025