OEM/ODM China High Quality Ceramic Fiber Insulation Board for High Temperature Furnace

We’ve got our possess gross sales group, structure crew, technical workforce, QC team and package group. We have now strict excellent control procedures for each approach. Also, all of our workers are experienced in printing field for OEM/ODM China High Quality Ceramic Fiber Insulation Board for High Temperature Furnace, We’re self-assured to create wonderful achievements while in the potential. We’ve been hunting forward to becoming one of your most trustworthy suppliers.

We’ve got our possess gross sales group, structure crew, technical workforce, QC team and package group. We have now strict excellent control procedures for each approach. Also, all of our workers are experienced in printing field for Ceramic Fiber Board and Ceramic Fiber Products, We expect to deliver merchandise and services to more users in global aftermarket markets; we launched our global branding strategy by providing our excellent products and solutions all over the world by virtue of our well reputed partners letting global users keep pace with technology innovation and achievements with us.

Product Information

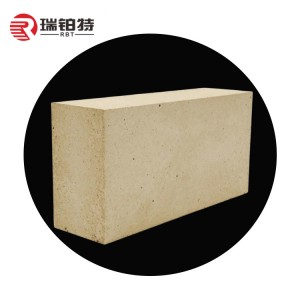

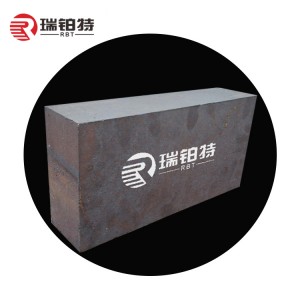

| Product Name | Ceramic Fiber Boards |

| Description | Ceramic fiber board generally refers to aluminum silicate fiber board. Aluminum silicate fiber board is processed by wet vacuum forming process. The strength of this type of product is higher than that of fiber blanket and vacuum forming felt, and it is suitable for high temperature fields that require rigid strength of the product. |

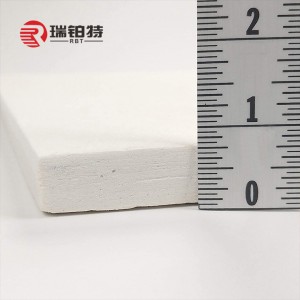

| Regular Size(mm) | 900/1000/1200*610/1200*25/50/100; Customized services available |

| Classification | Backing board; Fire baffle |

| Model | Common/Standard/High Purity/High Aluminum/Contains Zirconium/Zirconium Aluminum |

| Features |

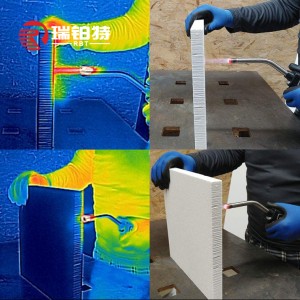

1. Excellent thermal shock resistance 2. Can be machined, cut and shaped easily 3. High rigidity and light weight 4. Low thermal conductivity 5. Low heat storage |

Details Images

Product Index

| INDEX | COM | STD | HC | HA | HZ | HAZ |

| Classification Temperature(℃) | 1050 | 1260 | 1260 | 1360 | 1430 | 1400 |

| Working Temperature(℃) ≤ | 1000 | 1050 | 1100 | 1200 | 1350 | 1200 |

| Slag Content(%) ≤ | 18 | 13 | 13 | 13 | 10 | 10 |

| Bulk Density(kg/m3) | 280~320 | |||||

| Thermal Conductivity(W/m.k) |

0.086 (400℃) 0.120 (800℃) |

0.086 (400℃) 0.120 (800℃) |

0.086 (400℃) 0.110 (800℃) |

0.092 (400℃) 0.186 (1000℃) |

0.092 (400℃) 0.186 (1000℃) |

0.98 (400℃) 0.20 (1000℃) |

| Permanent Linear Change×24h(%) | -4/1000℃ | -3/1000℃ | -3/1100℃ | -3/1200℃ | -3/1350℃ | -3/1400℃ |

| Modulus of Rupture(MPa) | 0.2 | |||||

| Al2O3(%) ≥ | 44 | 45 | 45 | 50 | 39 | 39 |

| Fe2O3(%) ≤ | 1.0 | 1.0 | 0.2 | 0.2 | 0.2 | 0.2 |

| Al2O3+SiO2(%) ≤ | 98 | 99 | 99 | 99 | 84 | 90 |

| ZrO2(%) ≥ | 11~13 | 5~7 | ||||

Application

1. It is used for backing insulation of kilns in cement and other building materials industries; 2. Kiln backing insulation in petrochemical, metallurgy, ceramics and glass industries; 3. Used for backing insulation of heat treatment kiln; 4. Backing insulation in non-ferrous metal industry; 5. High temperature reaction and heating equipment backing insulation; 6. Suitable for door seals and door curtains of various heat-insulated industrial kilns; 7. High temperature insulation and heat preservation of petrochemical equipment, containers and pipelines; 8. It can be used as heat insulation, fire barrier and automatic fire curtain in important places, such as archives, vaults and office building safes.

Package&Warehouse

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

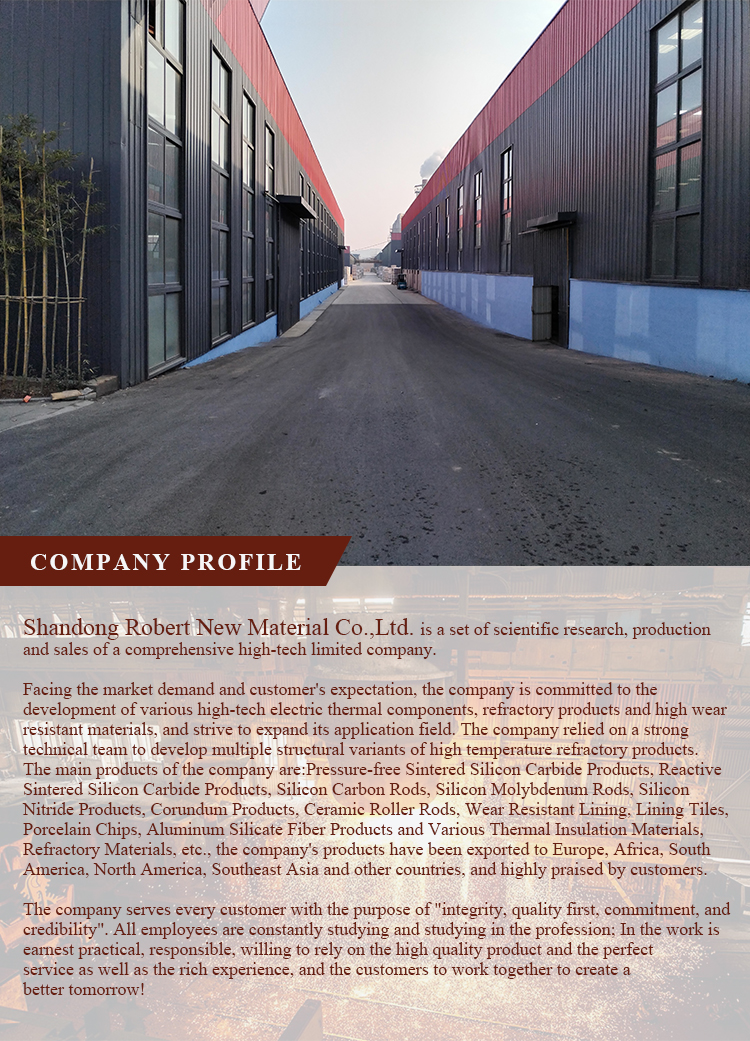

Are you a manufacturer or a trader?

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

How do you control your quality?

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

What is your delivery time?

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Do you provide free samples?

Of course, we provide free samples.

Can we visit your company?

Yes, of course, you are welcome to visit RBT company and our products.

What is the MOQ for trial order?

There is no limit, we can provide the best suggestion and solution according to your situation.

Why choose us?

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.

We’ve got our possess gross sales group, structure crew, technical workforce, QC team and package group. We have now strict excellent control procedures for each approach. Also, all of our workers are experienced in printing field for OEM/ODM China High Quality Ceramic Fiber Insulation Board for High Temperature Furnace, We’re self-assured to create wonderful achievements while in the potential. We’ve been hunting forward to becoming one of your most trustworthy suppliers.

OEM/ODM China Ceramic Fiber Board and Ceramic Fiber Products, We expect to deliver merchandise and services to more users in global aftermarket markets; we launched our global branding strategy by providing our excellent products and solutions all over the world by virtue of our well reputed partners letting global users keep pace with technology innovation and achievements with us.