OEM/ODM Manufacturer Redon Ceramic Fiber Blanket for Industrial Kilns

The really abundant projects management experiences and 1 to just one provider model make the high importance of business enterprise communication and our easy understanding of your expectations for OEM/ODM Manufacturer Redon Ceramic Fiber Blanket for Industrial Kilns, And we could aid looking for any products and solutions in the customers’ needs. Make sure deliver the top Support, the ideal Quality, The quick Delivery.

The really abundant projects management experiences and 1 to just one provider model make the high importance of business enterprise communication and our easy understanding of your expectations for Ceramic Fiber Blanket and Ceramic Fiber Cotton, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We now have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance are going to be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

Product Information

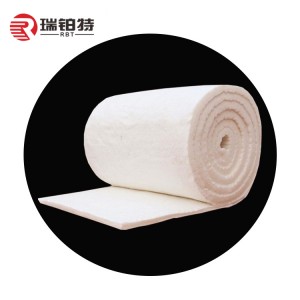

Ceramic fiber blanket is manufactured by refractory ceramic fibers, providing effective solutions to a wide range of thermal management problems.

Utilizing our proprietary high output blowing and spinning techniques, these products supply superior insulating performance, flexibility and resilience.

Features

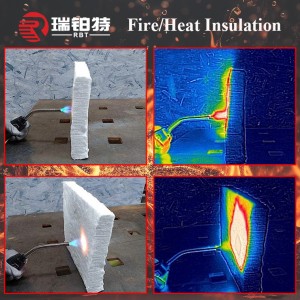

1. High temperature resistance, the highest operating temperature can reach 1300℃.

2. Low thermal conductivity, good thermal insulation performance. Under the same conditions, the thermal conductivity of aluminum silicate products is more than 30% lower than that of other insulation materials.

3. Light weight and good stability, with the characteristics of softness, lightness and elasticity. Dry products are 80-100 kg/m3, and wet products are 100-130 kg/m3.

4. Not wetted by molten metal. Has good chemical stability.

5. Good sound absorption and sound insulation performance, with good sound insulation effect.

6. Good electrical insulation, with a high dielectric constant; can be used as high-frequency insulation material.

Details Images

| Regular Size(mm) | 14400*610*12.5 3600*610*50 7200*610*25 |

| Model | COM/STD/HC/HA/HZ/HAZ |

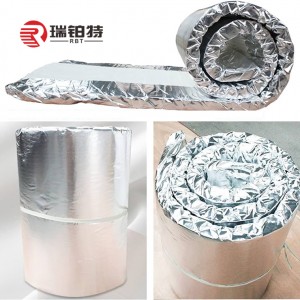

Details ImagesAluminum Foil Faced Ceramic Fiber Blanket

1. Fireproof Insulation: High-quality ceramic fiber insulation blanket backed with strong 50-micron thick Aluminum Foil is a high heat resistant non-combustible blanket, rated up to 1350℃ (on the side of the ceramic wool of blanket, not on the side of the aluminum foil attached)

2. Strong and Durable: This non-combustible blanket has high tensile strength and thermal shock resistance which allows it to maintain its soft structure without shrinkage when used within the recommended range of temperature.

3. Lightweight & Flexible: Being lightweight and flexible these blankets are extremely easy to install & work with. Moreover, they are easy to cut in the desired shape as well according to the need, making their installation effortless and hassle-free.

4. Enhanced Protection: These strong and durable ceramic fiber blankets with aluminum foil attached on one side are meant to provide surface protection to the blanket from external damage. Thus providing superior insulation value and protection to your parts/components or surface.

Product Index

| INDEX | COM | STD | HC | HA | HZ | HAZ |

| Classification Temperature(℃) | 1050 | 1260 | 1260 | 1360 | 1430 | 1400 |

| Working Temperature(℃) ≤ | 900 | 1050 | 1100 | 1200 | 1350 | 1200 |

| Slag Content(%) ≤ | 20 | 15 | 15 | 15 | 12 | 12 |

| Bulk Density(kg/m3) | 96~160 | |||||

| Thermal Conductivity(W/m.k) |

0.086 (400℃) 0.120 (800℃) |

0.086 (400℃) 0.120 (800℃) |

0.086 (400℃) 0.110 (800℃) |

0.092 (400℃) 0.186 (1000℃) |

0.092 (400℃) 0.186 (1000℃) |

0.98 (400℃) 0.20 (1000℃) |

| Permanent Linear Change×24h(%) | -4/1000℃ | -3/1000℃ | -3/1100℃ | -3/1200℃ | -3/1350℃ | -3/1400℃ |

| Modulus of Rupture(MPa) | 0.08~0.12 | |||||

| Al2O3(%) ≥ | 44 | 45 | 45 | 50 | 39 | 39 |

| Fe2O3(%) ≤ | 1.0 | 1.0 | 0.2 | 0.2 | 0.2 | 0.2 |

| Al2O3+SiO2(%) ≥ | 98 | 99 | 99 | 99 | 84 | 90 |

| ZrO2(%) | 13-15 | 5~7 | ||||

| Regular Size(mm) | 14400*610*12.5 3600*610*50 7200*610*25 | |||||

Application

Production Workshop

Package&Warehouse

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Robert`s products are widely used in high-temperature kilns such as non-ferrous metals, steel, building materials and construction, chemical, electric power, waste incineration, and hazardous waste treatment. They are also used in steel and iron systems such as ladles, EAF, blast furnaces, converters, coke ovens, hot blast furnaces; non-ferrous metallurgical kilns such as reverberators, reduction furnaces, blast furnaces, and rotary kilns; building materials industrial kilns such as glass kilns, cement kilns, and ceramic kilns; other kilns such as boilers, waste incinerators, roasting furnace, which have achieved good results in using. Our products are exported to Southeast Asia, Central Asia, Middle East, Africa, Europe, Americas and other countries, and has established a good cooperation foundation with multiple well-known steel enterprises. All employees of Robert sincerely look forward to working with you for a win-win situation.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

Are you a manufacturer or a trader?

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

How do you control your quality?

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

What is your delivery time?

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Do you provide free samples?

Of course, we provide free samples.

Can we visit your company?

Yes, of course, you are welcome to visit RBT company and our products.

What is the MOQ for trial order?

There is no limit, we can provide the best suggestion and solution according to your situation.

Why choose us?

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.

The really abundant projects management experiences and 1 to just one provider model make the high importance of business enterprise communication and our easy understanding of your expectations for OEM/ODM Manufacturer Redon Ceramic Fiber Blanket for Industrial Kilns, And we could aid looking for any products and solutions in the customers’ needs. Make sure deliver the top Support, the ideal Quality, The quick Delivery.

OEM/ODM Manufacturer Ceramic Fiber Blanket and Ceramic Fiber Cotton, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We now have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance are going to be expected as our principle of integrity. Devotion and Steadiness will remain as ever.