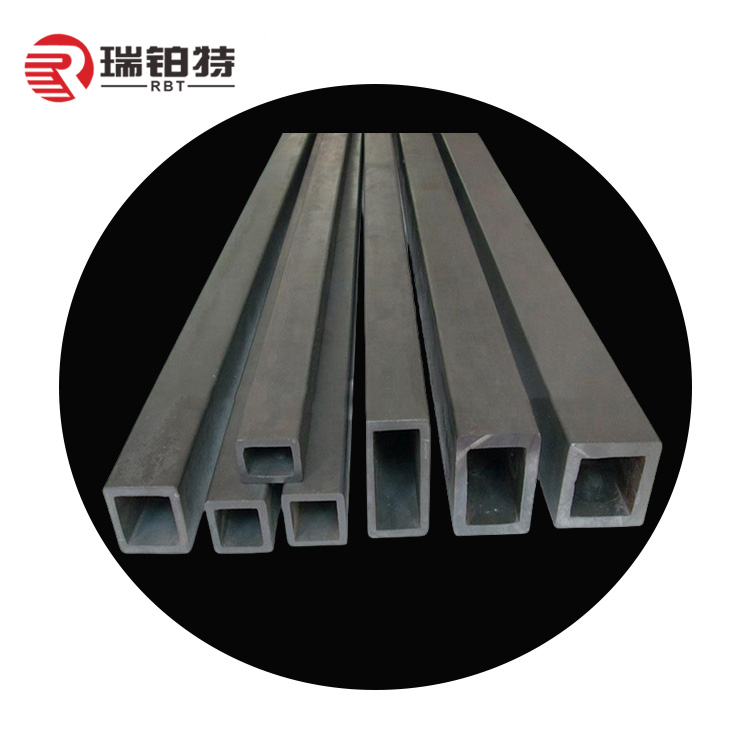

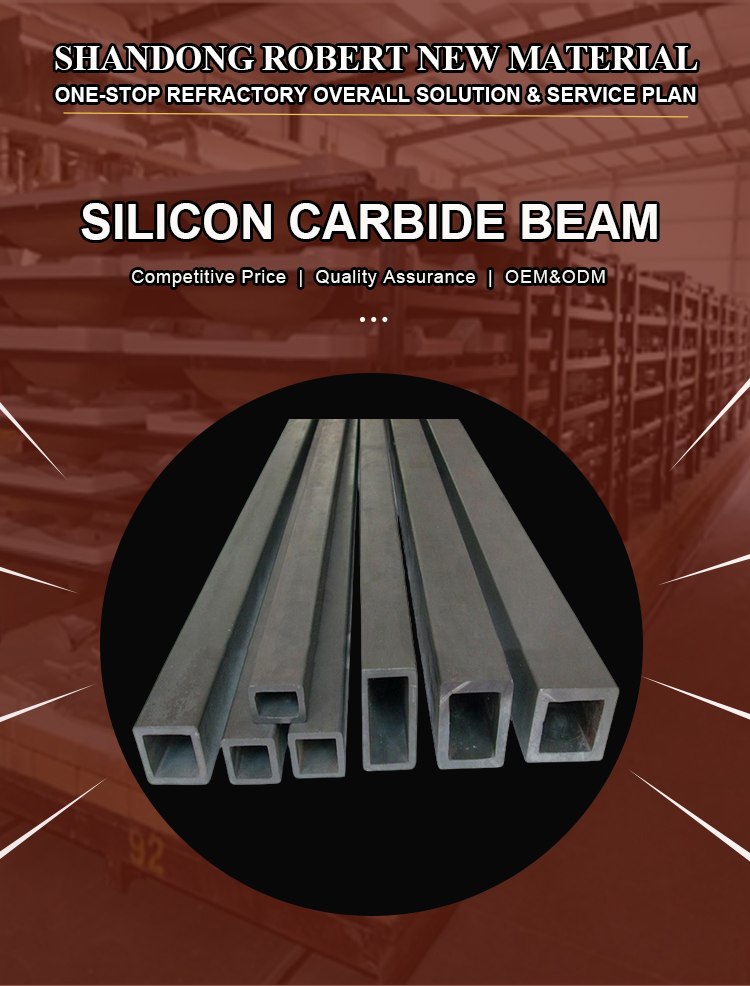

Personlized Products Refractory Silicon Carbide Sic Ceramics Beam

Each individual member from our significant effectiveness gross sales workforce values customers’ demands and small business communication for Personlized Products Refractory Silicon Carbide Sic Ceramics Beam, We welcome new and old consumers from all walks of everyday living to speak to us for upcoming business enterprise interactions and mutual accomplishment.

Each individual member from our significant effectiveness gross sales workforce values customers’ demands and small business communication for Cross Beam and Rbsic Beam, Our company promises: reasonable prices, short production time and satisfactory after-sales service, we also welcome you to visit our factory at any time you want. Wish we now have a pleasant and long terms business together!!!

Product Information

Silicon carbide beams have excellent high-temperature bearing capacity, good dimensional stability, and anti-oxidation and anti-corrosion capabilities. They have a long service life (below 1380 degrees) and will not break suddenly, will not get dirty or slag off, and will not pollute the fired products. They are suitable for load-bearing structural beams in tunnel kilns, shuttle kilns, double-layer roller kilns and other industrial kilns.

Features

1. High abrasion resistance

2. High energy efficiency

3. No deformation under high temperature

4. Maximum temperature tolerance 1650 degree celsius

5. Corrosion resistance

6. High bending strength under 1100 degree: 100-120MPA

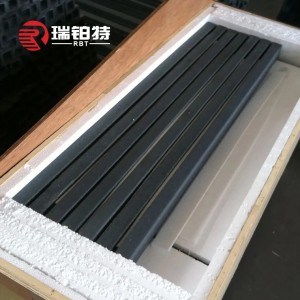

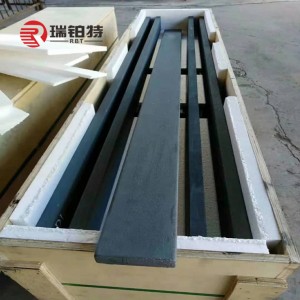

Details Images

Kiln Shelves

Product Index

| Reactive Sintering Silicon Carbide Beam | ||

| Item | Unit | Data |

| Max Temperature of Application | ℃ | ≤1380 |

| Density | g/cm3 | >3.02 |

| Open Porosity | % | ≤0.1 |

| Bending Strength | Mpa | 250(20℃); 280(1200℃) |

| Modulus of Elastictiy | Gpa | 330(20℃); 300(1200℃) |

| Thermal Conductivity | W/m.k | 45(1200℃) |

| Thermal Expansion Coefficient | K-1*10-6 | 4.5 |

| Moh’s Hardness | 9.15 | |

| Acid Alkaline-Proof | Excellent | |

| Bearing Capacity of RBSiC(SiSiC) Beams | ||||||

|

Size of Section (mm) |

Wall Thickness (mm) |

Concentrated Loading(kg.m/L) | Uniformly Distributed Loading(kg.m/L) | |||

| B Side | H Side | W Side | H Side | W Side | H Side | |

| 30 | 30 | 5 | 74 | 74 | 147 | 147 |

| 30 | 40 | 5 | 117 | 95 | 235 | 190 |

| 40 | 40 | 6 | 149 | 149 | 298 | 298 |

| 50 | 50 | 6 | 283 | 283 | 567 | 567 |

| 50 | 60 | 6 | 374 | 331 | 748 | 662 |

| 50 | 70 | 6 | 473 | 379 | 946 | 757 |

| 60 | 60 | 7 | 481 | 481 | 962 | 962 |

| 80 | 80 | 7 | 935 | 935 | 1869 | 1869 |

| 100 | 100 | 8 | 1708 | 1708 | 3416 | 3416 |

| 110 | 110 | 10 | 2498 | 2498 | 4997 | 4997 |

Application

Silicon carbide beams are particularly suitable for use as load-bearing structural frames in tunnel kilns, shuttle kilns, double-layer roller kilns and other industrial kilns. They are ideal kiln furniture for high-voltage electrical porcelain, sanitary porcelain, crystallized glass, refractory materials and other industries. The lifespan is several times that of other materials. (below 1680℃) can be used more than 100 times.

Package&Warehouse

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Robert`s products are widely used in high-temperature kilns such as non-ferrous metals, steel, building materials and construction, chemical, electric power, waste incineration, and hazardous waste treatment. They are also used in steel and iron systems such as ladles, EAF, blast furnaces, converters, coke ovens, hot blast furnaces; non-ferrous metallurgical kilns such as reverberators, reduction furnaces, blast furnaces, and rotary kilns; building materials industrial kilns such as glass kilns, cement kilns, and ceramic kilns; other kilns such as boilers, waste incinerators, roasting furnace, which have achieved good results in using. Our products are exported to Southeast Asia, Central Asia, Middle East, Africa, Europe, Americas and other countries, and has established a good cooperation foundation with multiple well-known steel enterprises. All employees of Robert sincerely look forward to working with you for a win-win situation.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

Are you a manufacturer or a trader?

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

How do you control your quality?

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

What is your delivery time?

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Do you provide free samples?

Of course, we provide free samples.

Can we visit your company?

Yes, of course, you are welcome to visit RBT company and our products.

What is the MOQ for trial order?

There is no limit, we can provide the best suggestion and solution according to your situation.

Why choose us?

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.

Each individual member from our significant effectiveness gross sales workforce values customers’ demands and small business communication for Personlized Products Refractory Silicon Carbide Sic Ceramics Beam, We welcome new and old consumers from all walks of everyday living to speak to us for upcoming business enterprise interactions and mutual accomplishment.

Personlized Products Cross Beam and Rbsic Beam, Our company promises: reasonable prices, short production time and satisfactory after-sales service, we also welcome you to visit our factory at any time you want. Wish we now have a pleasant and long terms business together!!!