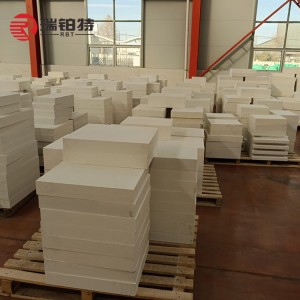

AZS Refractory Bricks 33/36/41

|

Product Name

|

AZS Bricks

|

|

Description

|

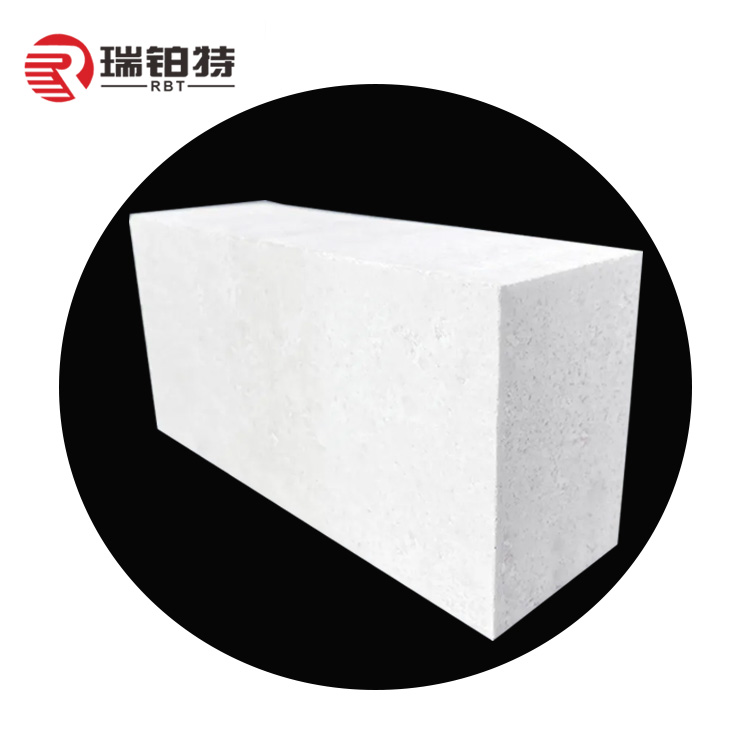

AZS block is also called fused zirconia corundum brick which contains Al2O3-ZrO2-SiO2. The fused cast AZS block is made of pure alumina powder and zircon sand (consisting of 65% zirconia and 34% SiO2). After the alumina powder and zircon sand are melted in an electric furnace, they are cast into various molds and cooled down to become white solids.

|

|

Model

|

AZS-33/AZS-36/AZS-41

|

|

Zirconia Contents

|

33% to 41%

|

|

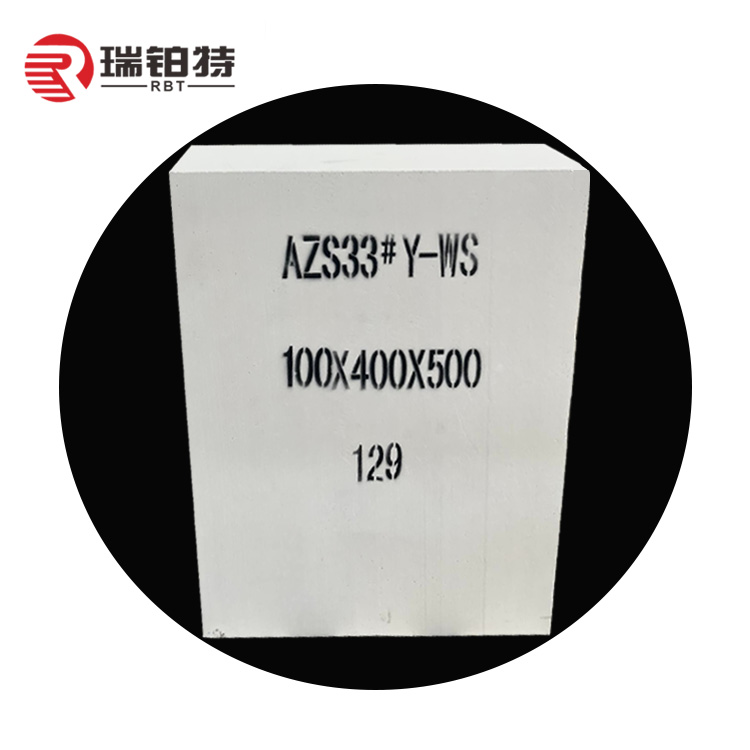

Size

|

Standard size: 230 x 114 x 65mm, special size and OEM service also provide!

|

|

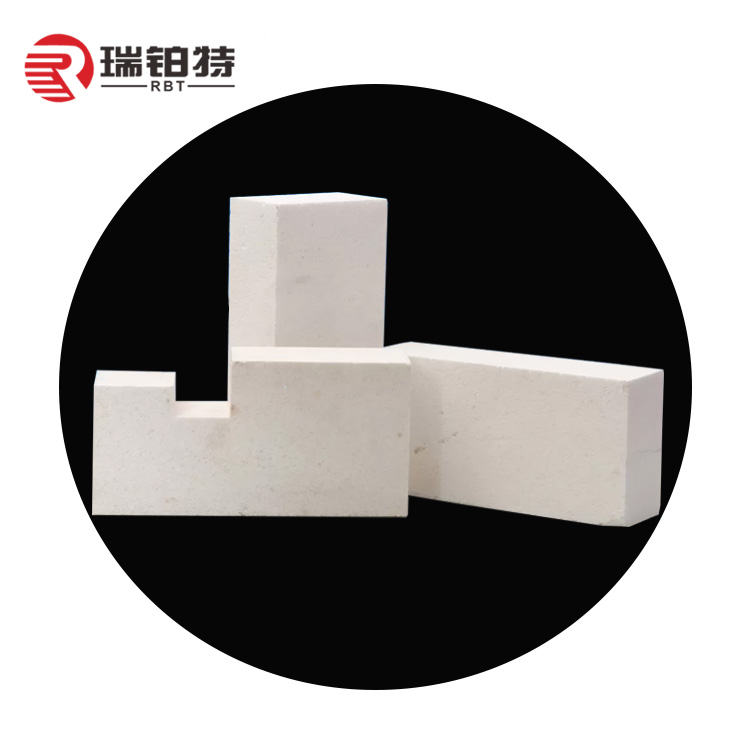

Shape

|

Straight bricks, special-shaped bricks

|

|

Features

|

1. High refractoriness;

2. Good thermal shock resistance; 3. Good creep-resisting property; 4. Good chemical stability; 5. Good high temperature strength and volume stability. 6. High erosion resistance |

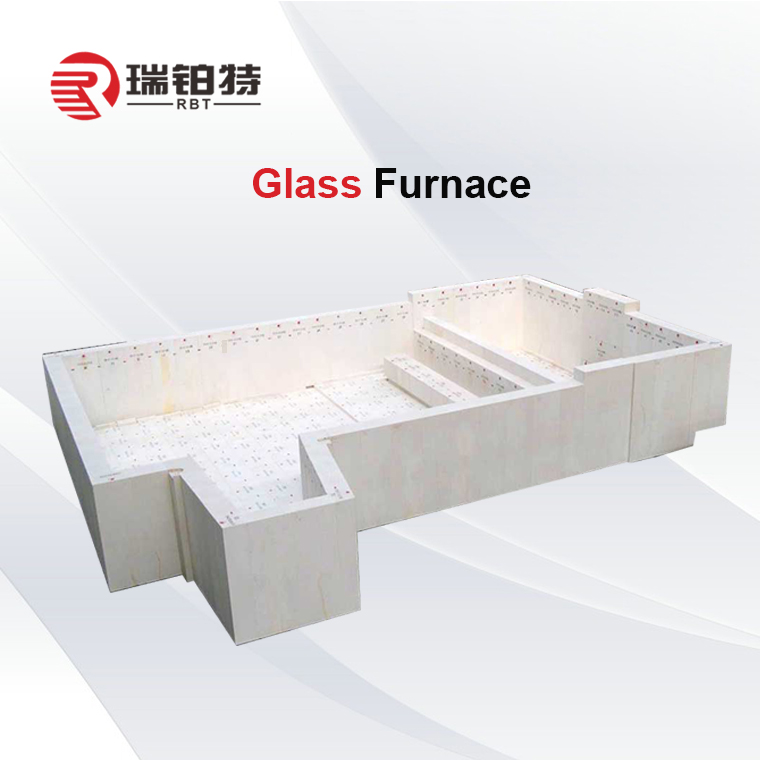

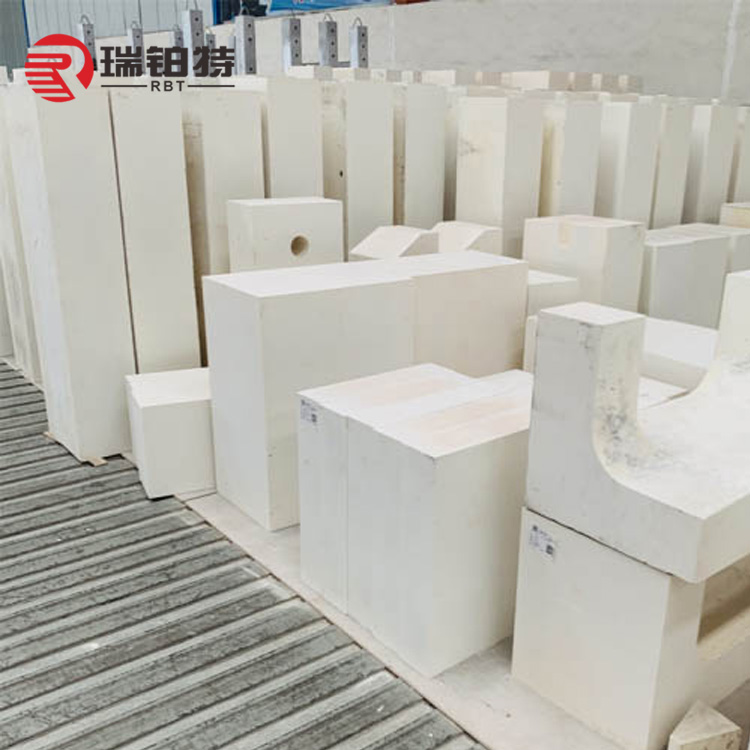

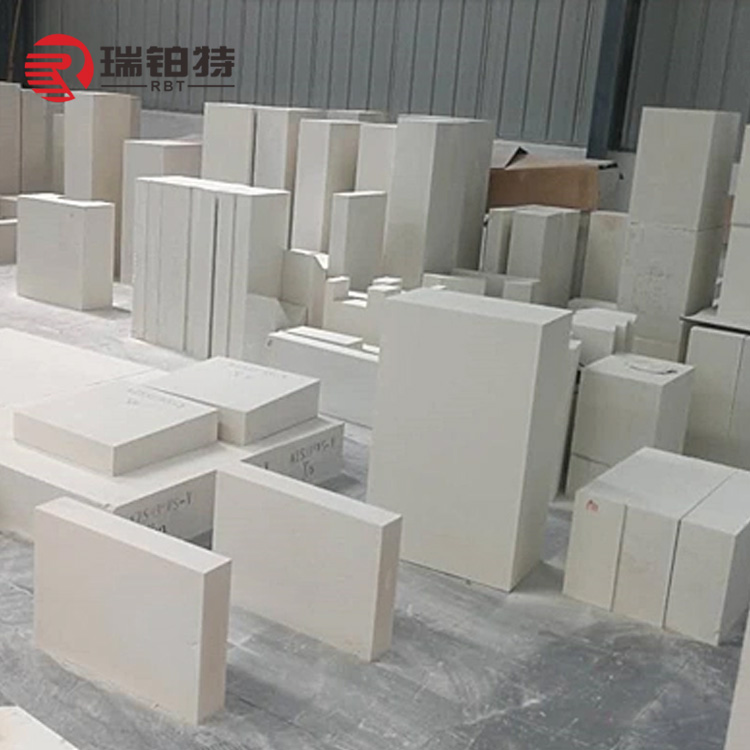

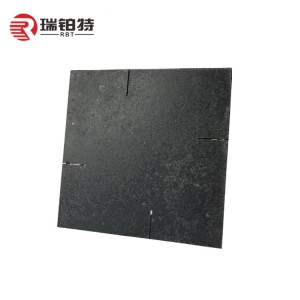

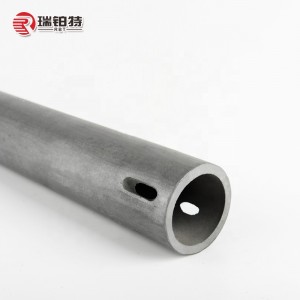

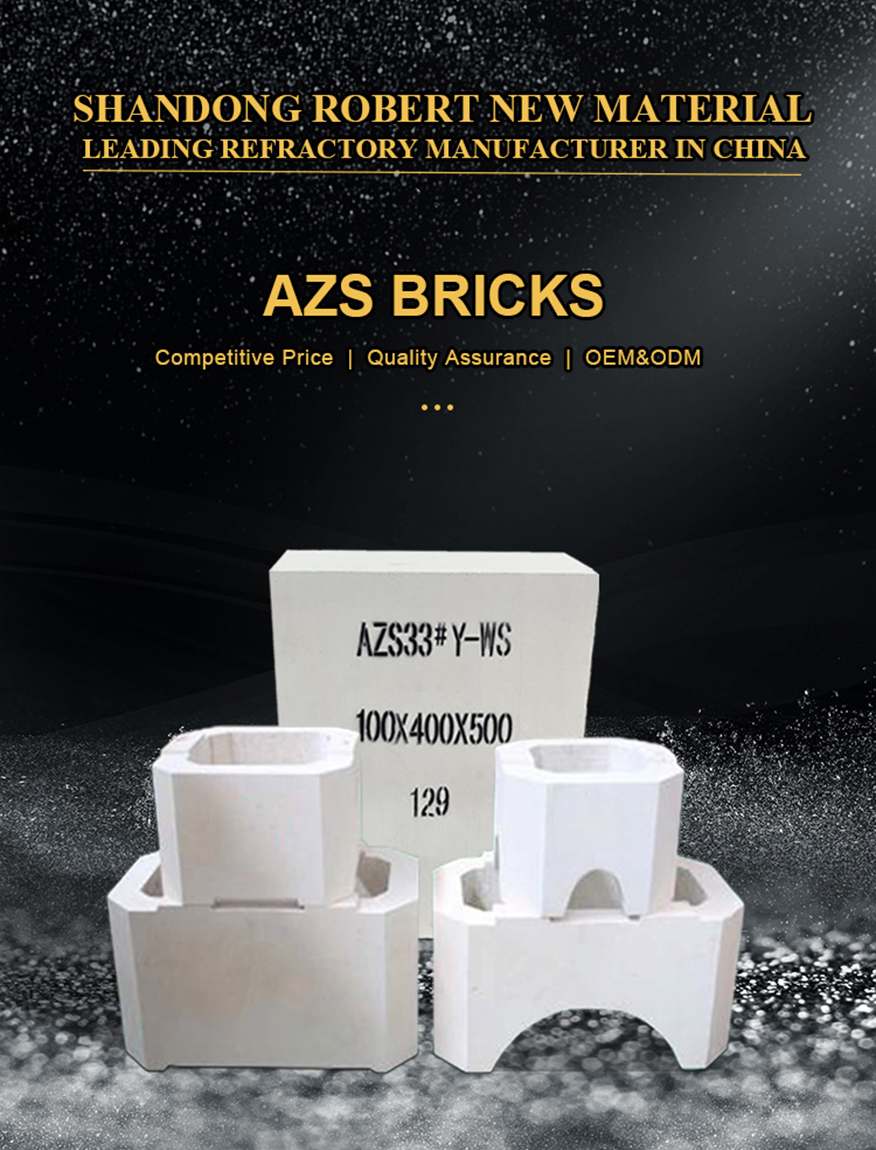

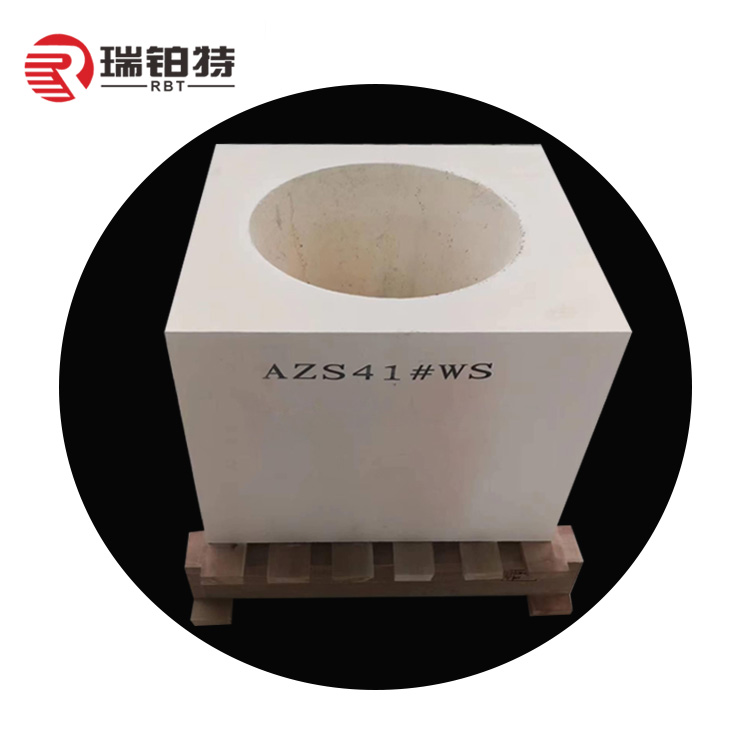

Details Images

Straight Bricks

Checker Bricks

Shaped Bricks

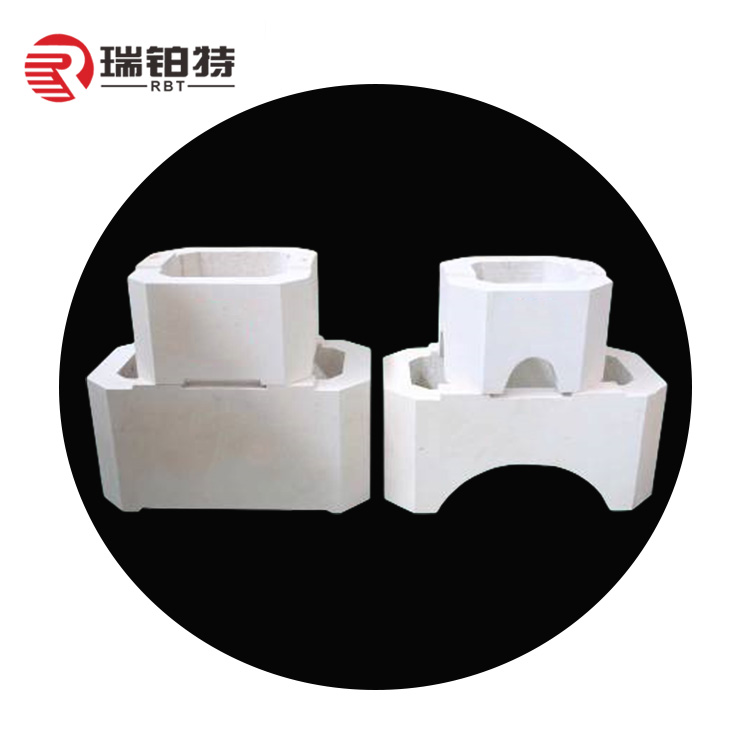

Shaped Bricks

Shaped Bricks

Shaped Bricks

Casting Method

|

Model

|

AZS-33

|

||

|

Casting Method

|

Description

|

Density

|

Application

|

|

Ordinary Casting

(PT)

|

It is a common casting method, and the shrinkage cavity of the product is located at the lower part of the casting port

|

≥3.40

|

Small stove top; melting pool; feed port feeder; non-glass contact area

|

|

Tilt Casting(QX)

|

The inclined casting method is adopted, and the shrinkage cavity of the product is biased at the lower end, which is mainly used as pool wall brick.

|

≥3.40

|

Melting pool wall

|

|

No Shrinkage Cavity Casting(WS)

|

Shrinkage-free product with the shrinkage cavity portion removed from the cast brick

|

≥3.70

|

Side wall, kiln ridge, pavement, special-shaped brick

|

|

Quasi Shrinkage Free Casting(ZWS)

|

Similar to non-shrinkage casting, the shrinkage cavity of the cast brick is basically removed.

|

≥3.60

|

Melting pool wall

|

|

Model

|

AZS-36

|

||

|

Casting Method

|

Description

|

Density

|

Application

|

|

Ordinary Casting

(PT)

|

It is a common casting method, and the shrinkage cavity of the product is located at the lower part of the casting port

|

≥3.50

|

Small stove top; melting pool; feed port feeder; non-glass contact area

|

|

Tilt Casting(QX)

|

The inclined casting method is adopted, and the shrinkage cavity of the product is biased at the lower end, which is mainly used as pool wall brick.

|

≥3.50

|

Melting pool wall

|

|

No Shrinkage Cavity Casting(WS)

|

The shrinkage cavity part of the cast brick is completely removed.

|

≥3.80

|

Melting pool wall, bottom plate, special-shaped brick

|

|

Quasi Shrinkage Free Casting(ZWS)

|

Similar to non-shrinkage casting, the shrinkage cavity of the cast brick is basically removed.

|

≥3.70

|

Melting pool wall

|

|

Model

|

AZS-41

|

||

|

Casting Method

|

Description

|

Density

|

Application

|

|

No Shrinkage Cavity Casting(WS)

|

Similar to quasi-shrinkless, the shrinkage cavity of the cast brick is completely removed.

|

≥3.90

|

Melting pool wall; liquid flow hole; corner of feeding port; bubbling brick; kiln chopping; electrode hole brick; special-shaped brick

|

|

Quasi Shrinkage Free Casting(ZWS)

|

Basically cut off the shrinkage cavity of the cast brick

|

≥3.85

|

Melting pool wall

|

Product Index

|

Item

|

AZS33

|

AZS36

|

AZS41

|

|

|

Chemical Composition(%)

|

Al2O3

|

≥50.00

|

≥49.00

|

≥45.00

|

|

ZrO2

|

≥32.50

|

≥35.50

|

≥40.50

|

|

|

SiO2

|

≤15.00

|

≤13.50

|

≤12.50

|

|

|

Na2O+K2O

|

≤1.30

|

≤1.35

|

≤1.30

|

|

|

Bulk density(g/cm3)

|

≥3.75

|

≥3.85

|

≥4

|

|

|

Apparent Porosity(%)

|

≤1.2

|

≤1.0

|

≤1.2

|

|

|

Cold Crushing Strength(Mpa)

|

≥200

|

≥200

|

≥200

|

|

|

Bubble Separation Ratio (1300ºC*10h)

|

≤1.2

|

≤1.0

|

≤1.0

|

|

|

Exudation Temperature of Glass Phase

|

≥1400

|

≥1400

|

≥1410

|

|

|

Anti-corrosion rate of glass liquid 1500ºC*36h(mm/24h) %

|

≤1.4

|

≤1.3

|

≤1.2

|

|

|

Apparent Density (g/cm3)

|

PT(RN RC N)

|

≥3.55

|

≥3.55

|

≥3.70

|

|

ZWS(RR EVF EC ENC)

|

≥3.65

|

≥3.75

|

≥3.85

|

|

|

WS( RT VF EPIC FVP DCL)

|

≥3.75

|

≥3.80

|

≥3.95

|

|

|

QX(RO)

|

≥3.65

|

≥3.75

|

≥3.90

|

|

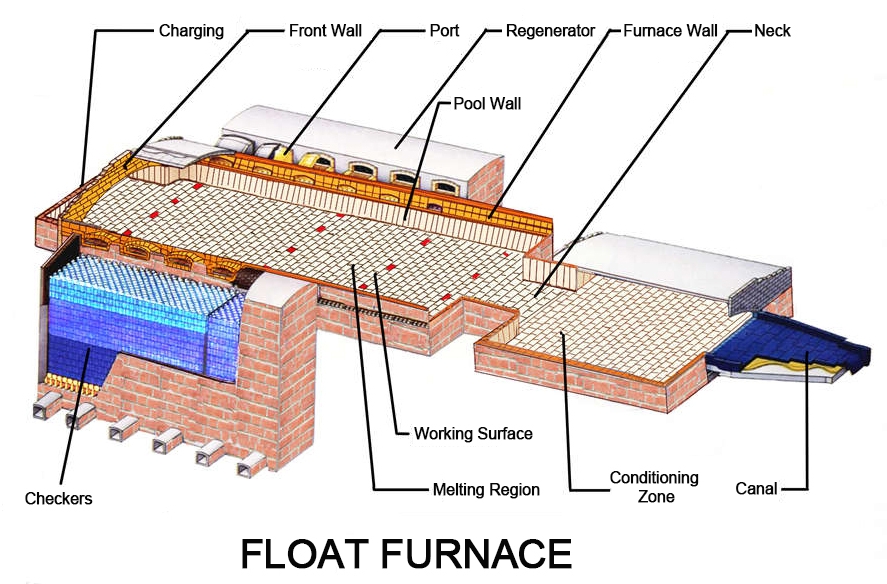

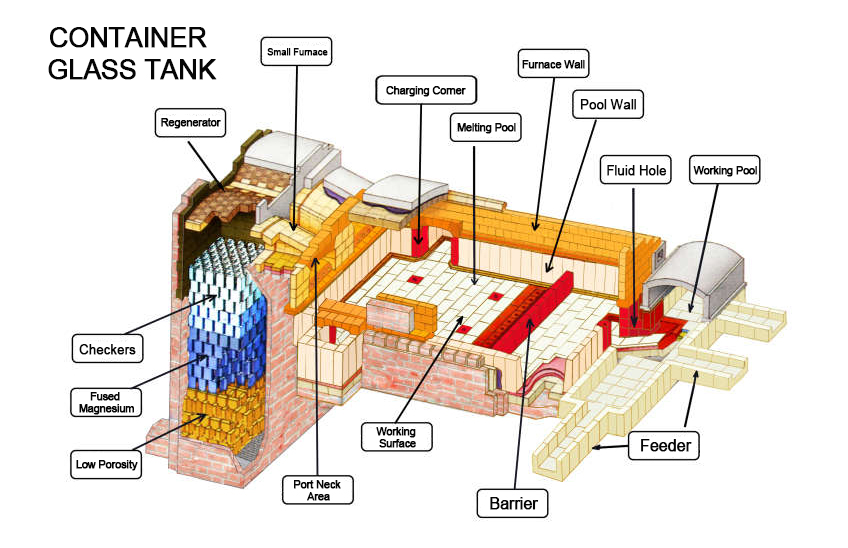

Application

|

Model

|

ZrO2

|

Application

|

|

AZS-33

|

33%

|

The dense microstructure of AZS33 makes the bricks have good resistance to glass liquid erosion, and it is not easy to produce stones or other defects in the glass kiln. It is a widely used product in glass melting furnaces, and is mainly suitable for the upper structure of the melting pool, the pool wall brick and paving brick of the working pool, and the forehearth, etc.

|

|

AZS-36

|

36%

|

In addition to having the same eutectic as AZS33, AZS36 bricks have more chain-like zirconia crystals and lower glass phase content, so the corrosion resistance of AZS36 bricks is further enhanced, so it is suitable for glass liquids with faster flow rates. or higher temperature areas.

|

|

AZS-41

|

41%

|

In addition to eutectics of silica and alumina, it also contains more uniformly distributed zirconia crystals. In the zirconium corundum brick system, it has good corrosion resistance. Therefore, key parts of the glass furnace are selected to balance the life of these parts with other parts.

|

Float Glass

Medicinal Glass

Daily Use Glass

Food Grade Glass

Package&Warehouse