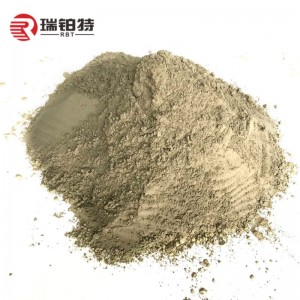

Premium Mortar for High-Temperature Bonding

Description

Classification

Refractory mortar, also known as fire mortar or joint material (powder), used as bonding refractory products brickwork materials, according to the material can be divided into clay, high aluminum, silicon and magnesium refractory mortar, etc.

It is called ordinary refractory mortar made of refractory clinker powder and plastic clay as binder and plastic agent. Its strength at room temperature is low, and the formation of ceramic bonding at high temperature has high strength.

With hydraulicity, air hardening or thermo-hardening materials as binder, called chemical binding refractory mortar, as below the formation of ceramic binding temperature before the production of a certain chemical reaction and hardening.

Features

Refractory mortar characteristics: good plasticity, convenient construction; high bond strength, strong corrosion resistance; high refractoriness, up to 1650℃±50℃; good slag invasion resistance; good thermal spalling property.

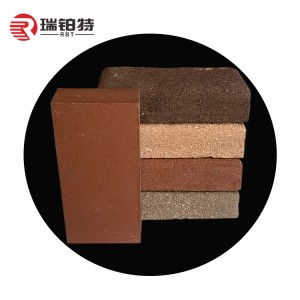

Application

Refractory mortar is mainly used in coke oven, glass kiln, blast furnace, hot blast stove, metallurgy, architectural material industry, machinery, petrochemical, glass, boiler, electric power, iron and steel, cement and other industrial kiln.

Product Index

|

INDEX |

Clay |

High aluminum |

Corundum |

Silica |

Magnesium |

light clay |

|||||||

|

RBT MN -42 |

RBT MN -45 |

RBT MN -55 |

RBT MN -65 |

RBT MN -75 |

RBT MN -85 |

RBT MN -90 |

RBT GM -90 |

RBT MF -92 |

RBT MF -95 |

RBT MF -97 |

RBT MM -50 |

||

|

Refractoriness(℃) |

1700 |

1700 |

1720 |

1720 |

1750 |

1800 |

1820 |

1670 |

1790 |

1790 |

1820 |

|

|

|

CCS/MOR (MPa)≥ |

110℃×24h |

1.0 |

1.0 |

2.0 |

2.0 |

2.0 |

2.0 |

2.0 |

1.0 |

1.0 |

1.0 |

1.0 |

0.5 |

|

1400℃×3h |

3.0 |

3.0 |

4.0 |

4.0 |

4.0 |

3.5 |

3.0 |

3.0 |

3.0 |

3.0 |

3.0 |

1.0 |

|

|

Bonding Time(min) |

1~2 |

1~2 |

1~2 |

1~2 |

1~2 |

1~3 |

1~3 |

1~2 |

1~3 |

1~3 |

1~3 |

1~2 |

|

|

Al2O3(%) ≥ |

42 |

45 |

55 |

65 |

75 |

85 |

90 |

— |

— |

— |

— |

50 |

|

|

SiO2(%) ≥ |

— |

— |

— |

— |

— |

— |

— |

90 |

— |

— |

— |

— |

|

|

MgO(%) ≥ |

— |

— |

— |

— |

— |

— |

— |

— |

92 |

95 |

97 |

— |

|