Silica Refractory Bricks

|

Product Name

|

Silica bricks/Silicon bricks

|

|

Content

|

94%/96%

|

|

Material

|

Silica

|

|

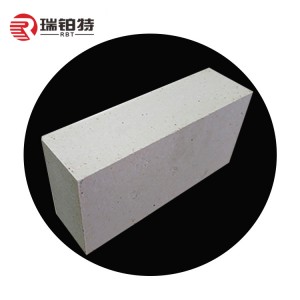

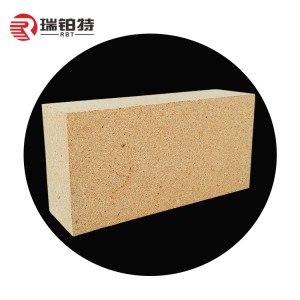

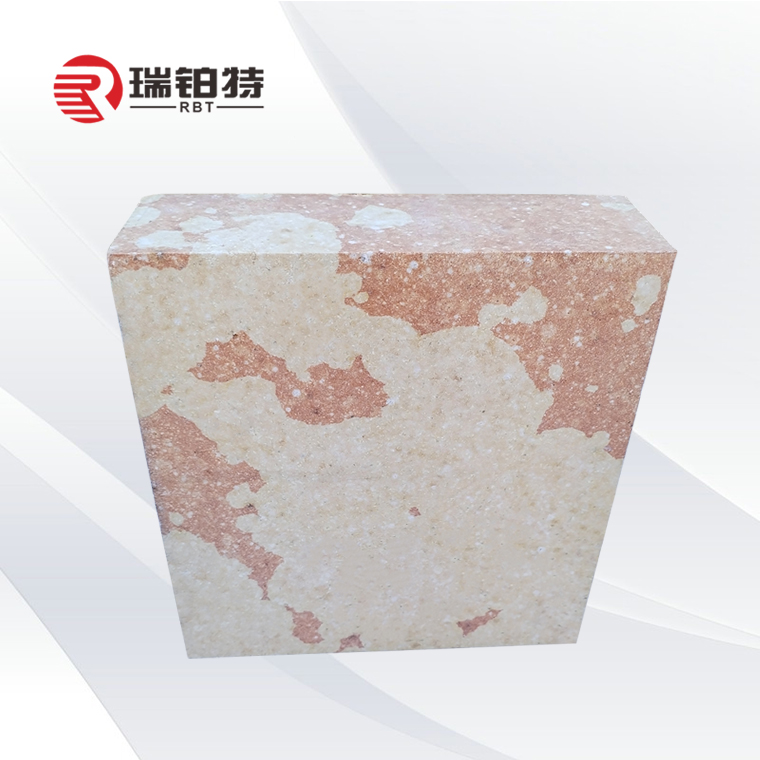

Color

|

Light yellow

|

|

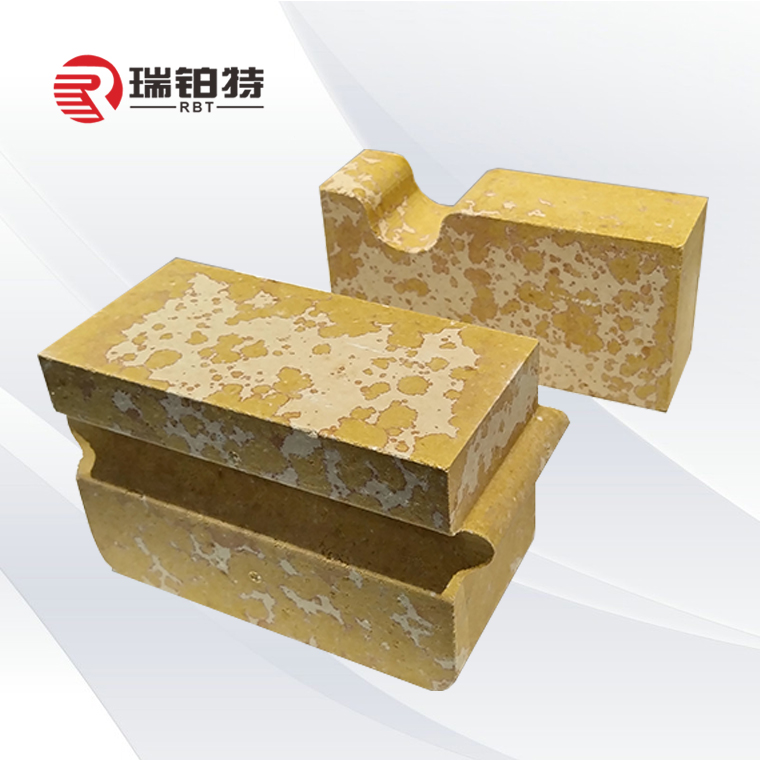

Shape

|

Straight bricks, special-shaped bricks, customers' requirement

|

|

Size

|

Standard size: 230 x 114 x 65mm, special size and OEM service also provide!

|

|

Features

|

It has strong corrosion resistance to acidic slag and has a high load softening temperature. Silica bricks will undergo irreversible volume expansion when heated below 600°C, which will make the joints close and ensure good air tightness and structural strength of the masonry.

|

Description

Silicon bricks are a refractory product with silicon dioxide as the main component and its content is more than 94%. The higher the SiO2 content of the silica raw material, the higher the refractoriness. It belongs to acid refractory material, so it has strong resistance to acid slag erosion and has higher softening temperature under load.

Features

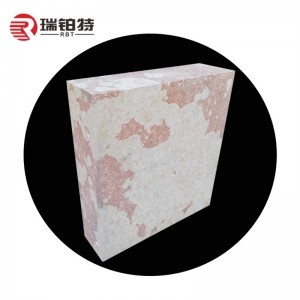

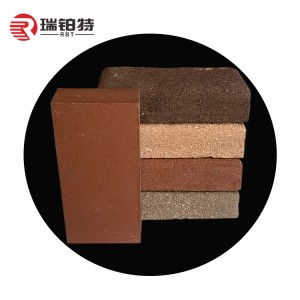

Silicon Wedge Bricks

High Thermal Conductivity Silica Bricks

Silica Bricks

Silica Bricks

Silica Bricks

High Thermal Conductivity Silica Bricks

Silica Bricks

Silica Bricks

Product Index

|

INDEX

|

RBTG-94

|

RBTG-95

|

RBTG-96A

|

RBTG-96B

|

|

Refractoriness(℃) ≥

|

1710

|

1710

|

1710

|

1710

|

|

Bulk Density(g/cm3) ≥

|

1.8

|

1.8

|

1.87

|

1.8

|

|

True Density(g/cm3) ≤

|

2.35

|

2.35

|

2.34

|

2.34

|

|

Apparent Porosity(%) ≤

|

22

|

21

|

21

|

21

|

|

Cold Crushing Strength(MPa) ≥

|

30

|

32

|

35

|

35

|

|

Permanent Linear Change @1500°×2h(%)

|

0 +3

|

0 +3

|

0 +3

|

0 +3

|

|

Refractoriness Under Load @0.2MPa(℃) ≥

|

1630

|

1650

|

1650

|

1680

|

|

SiO2(%) ≥

|

94

|

95

|

96

|

96

|

|

Fe2O3(%) ≤

|

1.5

|

1.5

|

0.8

|

0.7

|

|

Al2O3+TiO2+R2O(%) ≤

|

|

1.0

|

0.7

|

0.8

|

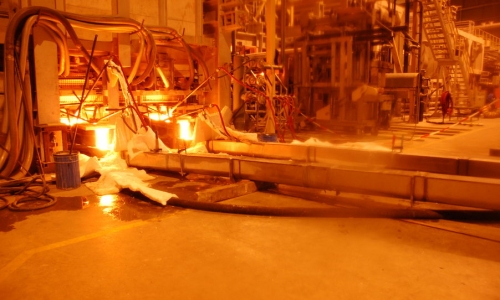

Application

1. The silicon bricks are mainly used in the partition wall of the carbonization chamber and combustion chamber of the coke oven, the regenerator chamber and sediment chamber of the open hearth furnace of the steel making , the average heating furnace, the refractory material of the glass melting kiln and the kiln of the ceramic, and other bearing parts of the kiln.

Hot Blast Stove

Glass Stove

Coke Oven

Package&Warehouse