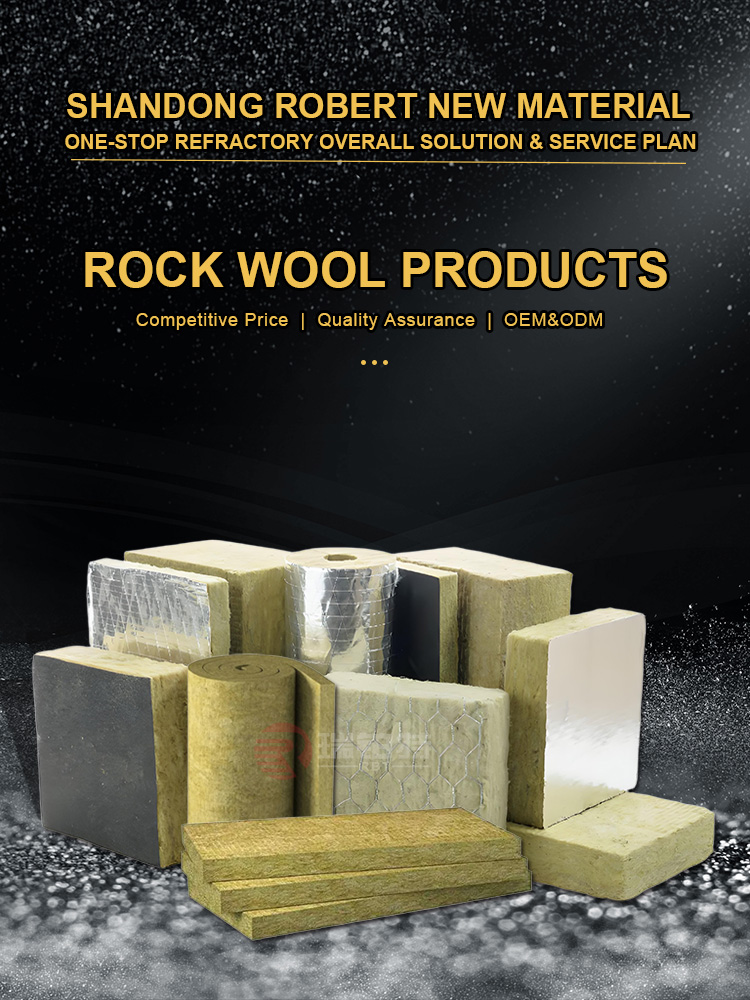

Rock Wool Boards

Product Description

Rock wool products are made of high-quality natural rocks as the main raw materials, such as basalt, gabbro, dolomite, etc., with an appropriate amount of binder added. They are processed by high-temperature melting and high-speed centrifugal fiber solidification in a four-roll centrifuge. They are then collected by a capture belt, pleated by a pendulum, solidified, and cut to form products of different specifications. The water-repellent rate of waterproof rock wool products can reach more than 98%. Because they do not contain fluorine or chlorine, they have no corrosive effect on equipment.

Characteristics

Thermal insulation performance: Rockwool products have good thermal insulation performance, can effectively reduce heat transfer and save energy.

Fire resistance: Rockwool products have excellent fire resistance and are non-combustible materials. They can block the spread of flames in fires.

Sound absorption and noise reduction: Due to its porous structure, rockwool products have good sound absorption and noise reduction effects, and are suitable for places that require a quiet environment.

Environmental protection performance: The production and recycling process of rockwool products meets environmental protection requirements and has good recycling characteristics.

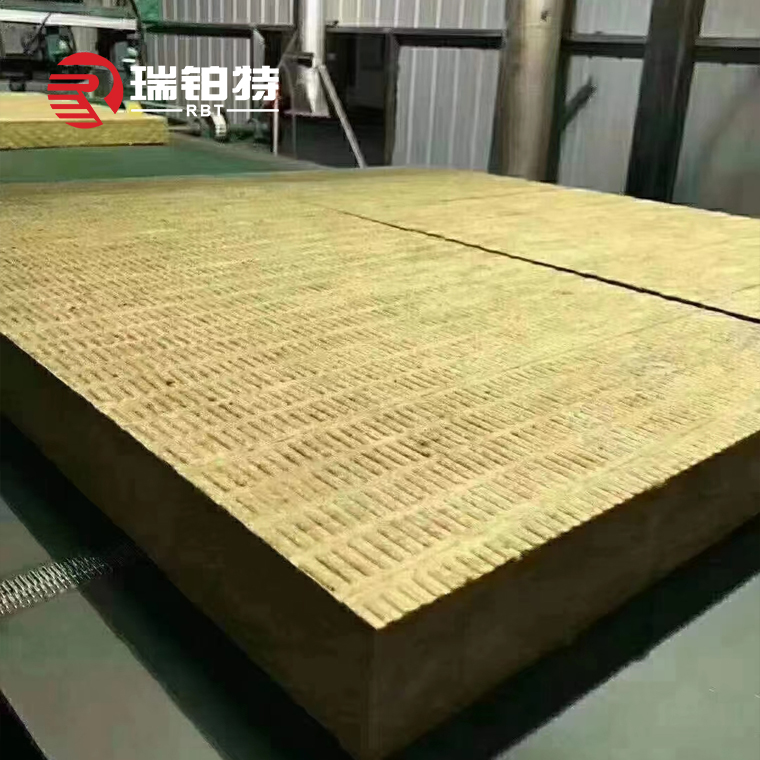

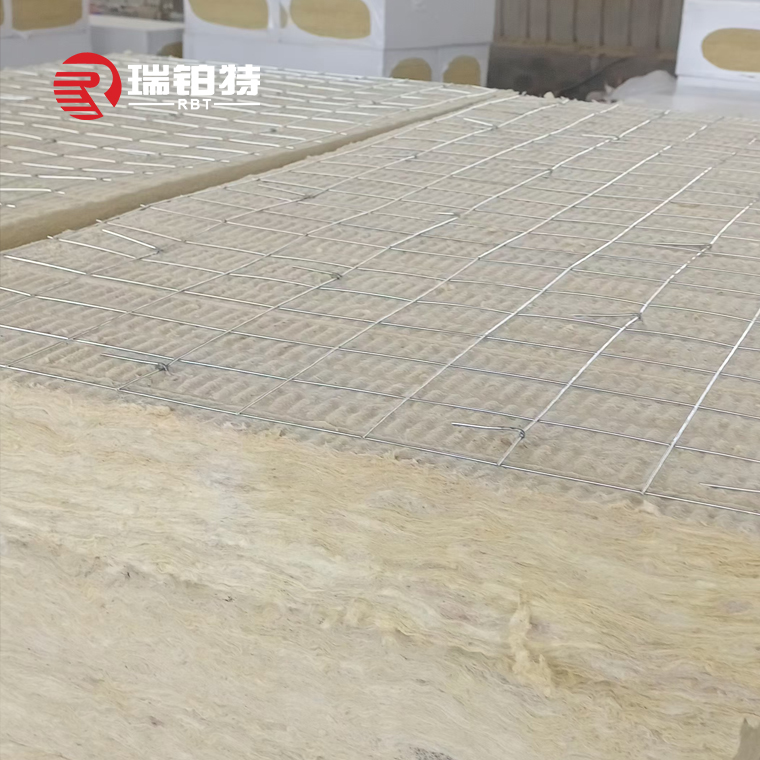

Details Images

|

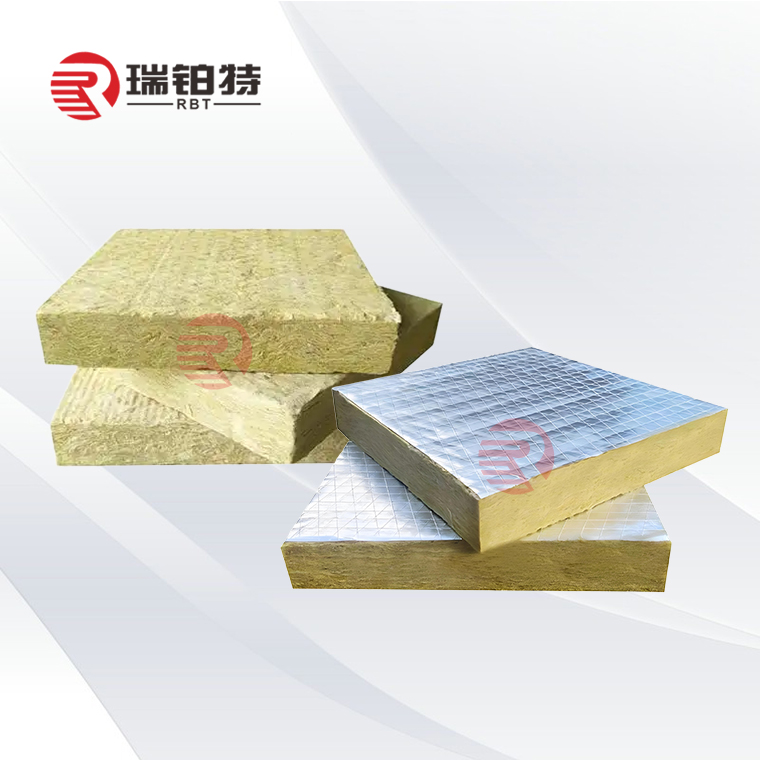

Bulk Density

|

60-200kg/m3

|

|

Maximum Operating Temperature

|

650℃

|

|

Fiber Diameter

|

4-7um

|

|

Specification

|

1000-1200mm*600-630mm*30-150mm

|

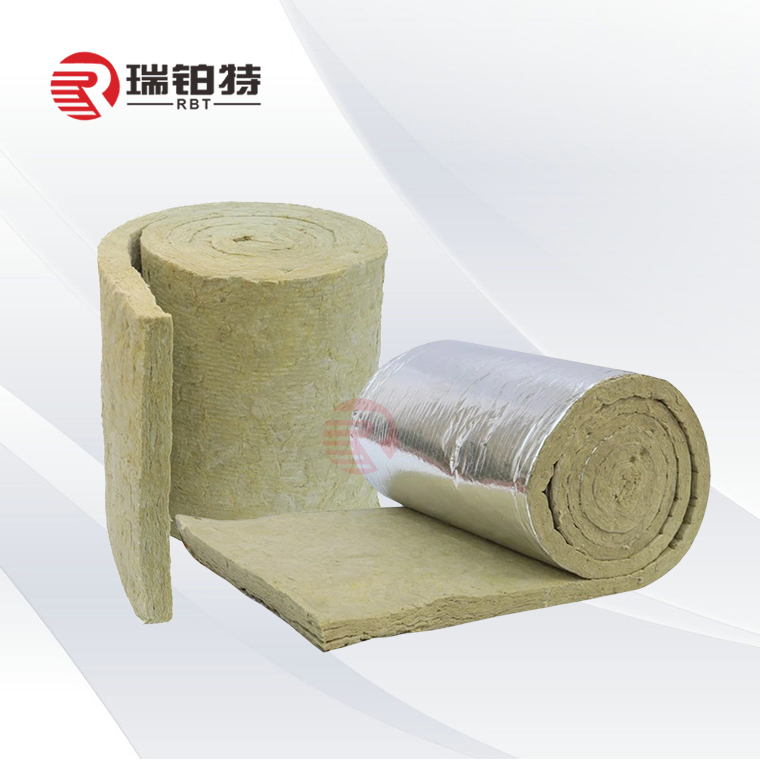

Rock Wool Blankets with Foil

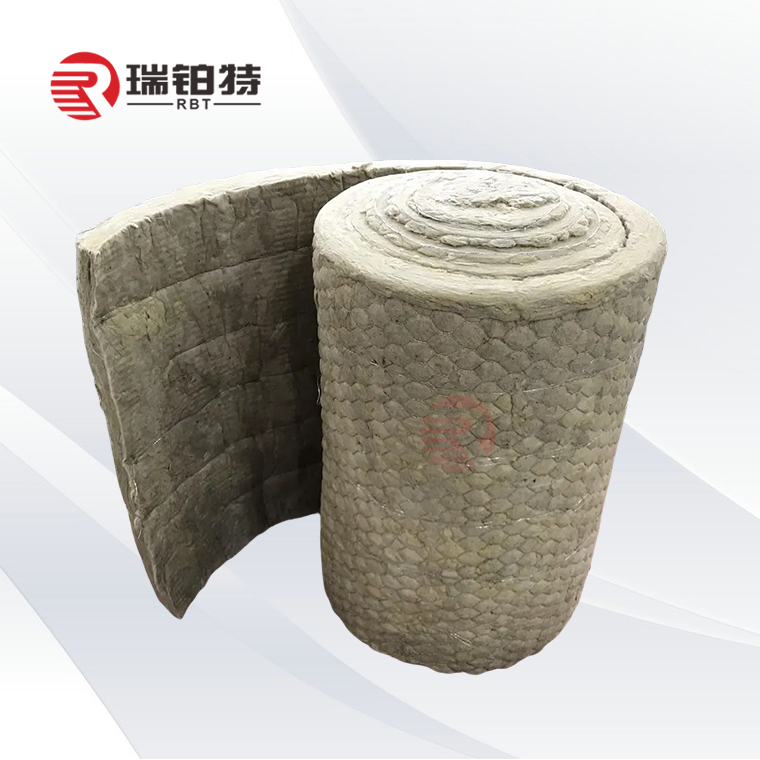

Rock Wool Blankets with Wire Mesh

Rock Wool Boards with Foil

Product Index

|

Item

|

Unit

|

Index

|

|

Thermal conductivity

|

w/m.k

|

≤0.040

|

|

Tensile strength perpendicular to the board surface

|

Kpa

|

≥7.5

|

|

Compressive strength

|

Kpa

|

≥40

|

|

Flatness deviation

|

mm

|

≤6

|

|

Degree of deviation from right angle

|

mm/m

|

≤5

|

|

Slag ball content

|

%

|

≤10

|

|

Average fiber diameter

|

um

|

≤7.0

|

|

Short-term water absorption

|

kg/m2

|

≤1.0

|

|

Mass moisture absorption

|

%

|

≤1.0

|

|

Acidity coefficient

|

|

≥1.6

|

|

Water repellency

|

%

|

≥98.0

|

|

Dimensional stability

|

%

|

≤1.0

|

|

Combustion performance

|

|

A

|

Application

Building Insulation: Rock wool products are often used for insulation of walls, roofs, floors and other parts of buildings due to their excellent insulation properties. This helps reduce energy consumption and improve the energy efficiency of buildings.

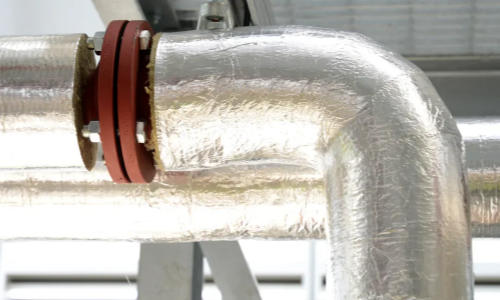

Industrial Equipment Insulation: In the industrial field, rock wool products are used for insulation of various high-temperature equipment, such as boilers, pipes, storage tanks, etc. It not only prevents heat loss, but also protects equipment and personnel from high temperature damage.

Sound insulation and noise reduction: Rock wool products have good sound insulation and noise reduction properties and are often used in places where noise reduction is required, such as theaters, concert halls, recording studios, etc.

Fire protection: Rock wool products are a non-combustible material and are often used in places where fire protection is required, such as firewalls, fire doors, fire windows, etc.

Ship applications: Rock wool products are also widely used on ships, such as thermal insulation and heat insulation in cabins, sanitary units on board, crew lounges and power compartments.

Other special uses: Rock wool products can also be used for thermal insulation and sound insulation and noise reduction in the fields of vehicles, aerospace, etc.

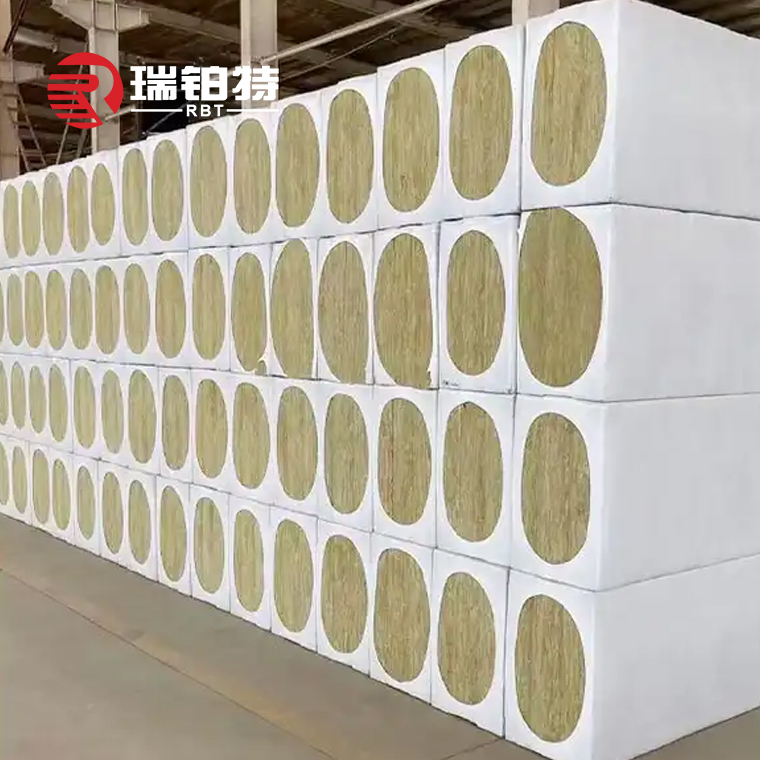

Package&Warehouse

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.