Silica Mullite Brick

Product Information

Silicon-mullite brick is a high-grade refractory material. The main raw materials include high-alumina bauxite clinker and silicon carbide, which are made through processes such as mixing, molding, drying and high-temperature firing. The key step is the high-temperature firing stage, which forms an ideal mullite crystal structure by reasonably controlling the temperature and atmosphere. It has high refractoriness, excellent wear resistance and good thermal shock resistance. It can maintain stability in high temperature environments and is not easy to crack or peel off.

Feature: High refractoriness; Excellent thermal shock resistance; Good chemical resistance; High mechanical strength; Low thermal expansion.

Silicon-molybdenum andalusite bricks are mainly composed of special high-alumina bauxite, large-crystal silicon carbide, andalusite, fused white corundum and other raw materials. They are made by adding high-quality binders and additives, and are formed by high-pressure molding and high-temperature sintering. This production process ensures the high density and excellent physical properties of silicon-molybdenum red bricks.

Features: High strength and wear resistance; Good durability; Good thermal insulation performance; Good high temperature performance; High thermal shock resistance.

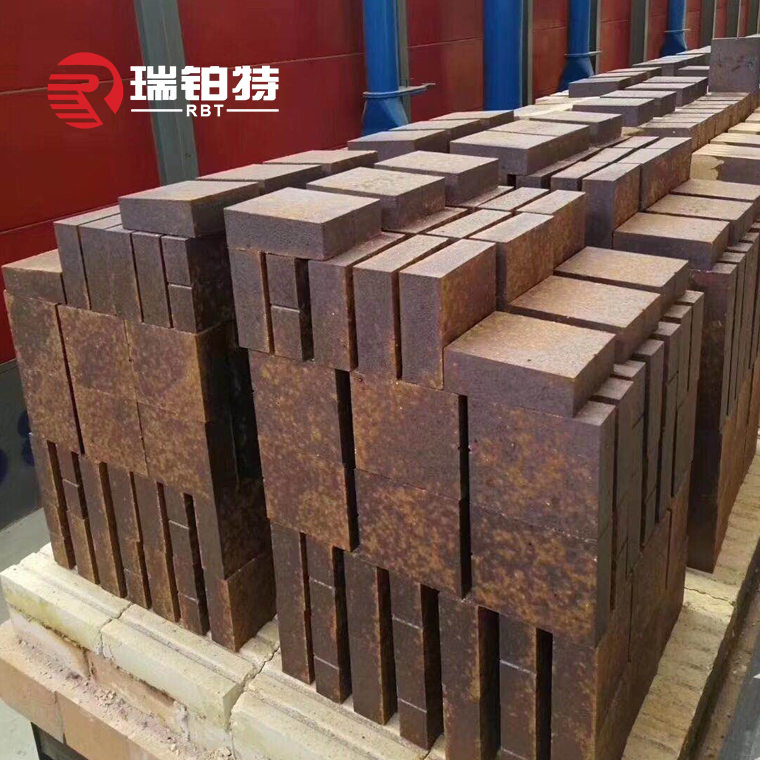

Details Images

Product Index

|

PRODUCT

|

Silica Mullite Andalusite Brick

|

Silica Mullite Brick

|

||

|

INDEX

|

RBTSMH-1680

|

RBTSM-1680

|

RBTSM-1650

|

RBTSM-1550

|

|

Bulk Density(g/cm3) ≥

|

2.65

|

2.65

|

2.6

|

2.5

|

|

Apparent Porosity(%) ≤

|

17

|

17

|

17

|

19

|

|

Cold Crushing Strength(MPa) ≥

|

90

|

90

|

85

|

80

|

|

Thermal Shock Resistance

Water Cool 1100°(times)

|

15

|

12

|

10

|

10

|

|

Refractoriness Under Load@0.2MPa(℃) ≥

|

1680

|

1680

|

1650

|

1550

|

|

SiO2+SiC(%) ≤

|

30

|

30

|

30

|

28

|

|

Al2O3(%) ≥

|

68

|

65

|

65

|

60

|

Application

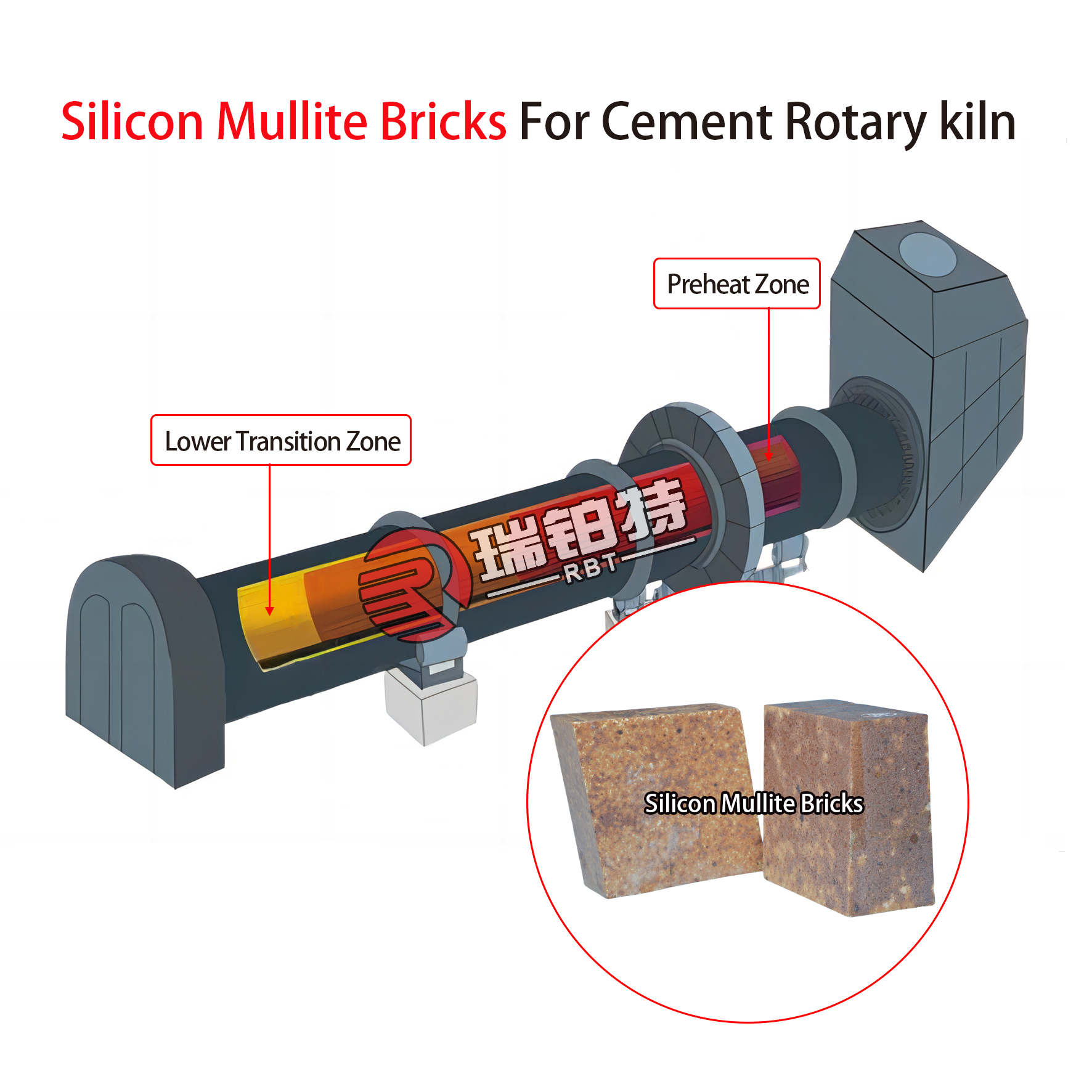

Silicon-molybdenum andalusite bricks are widely used in transition zones and cooling zones of large and medium-sized cement rotary kilns. Due to its excellent fire resistance and wear resistance, silicon-molybdenum red bricks can effectively improve the service life and performance of equipment.

In cement rotary kilns, silicon-molybdenum bricks are mainly used in transition zones, preheating zones, tertiary air ducts, five-stage preheaters, and lime kiln unloading chutes. They are resistant to erosion, spalling, and good thermal shock stability.

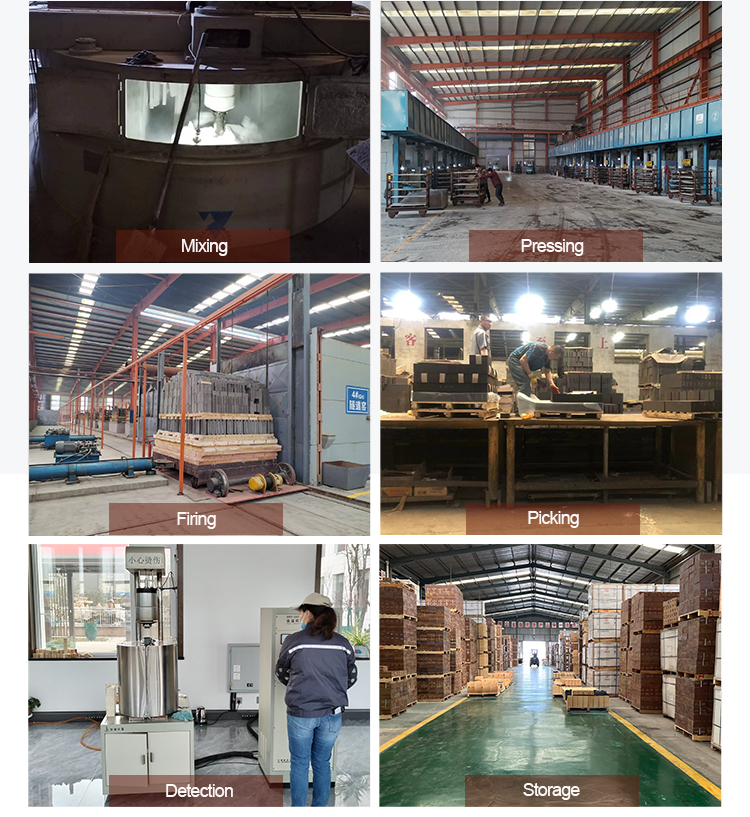

Production Process

Package&Warehouse

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.