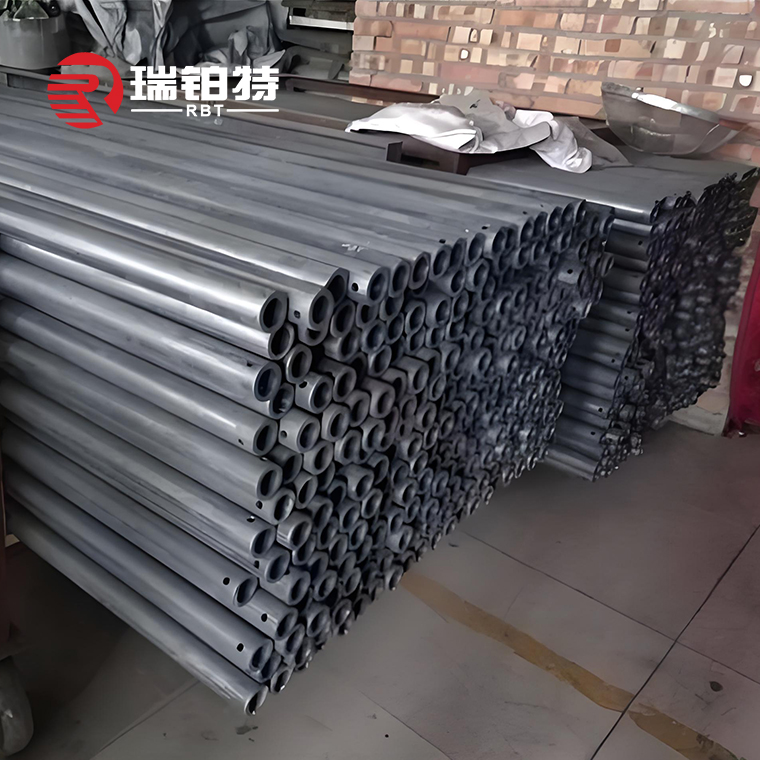

Silicon Carbide Heat Radiation Tube

Product Information

1. SSiC Products(Atmospheric Sintering Silicon Carbide Products)

(1) This material is a dense SiC ceramic product made by pressureless sintering of high performance sub-micron SiC powder. It does not contain free silicon and has fine grains.

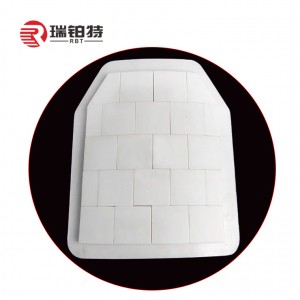

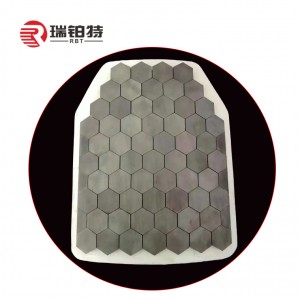

(2) It is currently the preferred general material for the international and domestic manufacturing of mechanical seal rings, sandblasting nozzles, bulletproof armor, magnetic pumps, and canned pump components.

(3) It is especially suitable for use in the transportation of corrosive media such as strong acids and strong alkali.

Features:

(1) High strength, high hardness, wear resistance, density up to 3.1kg/m3.

(2) High attenuation performance, low thermal expansion, high thermal shock resistance, high temperature creep resistance.

(3) Chemical stability, corrosion resistance, especially hydrofluoric acid resistance.

(4) High-temperature resistance, maximum operating temperature up to 1380 ℃.

(5) Long service life and reduce overall investment cost.

2. RBSIC(SiSiC) Products(Reactive Sintering Silicon Carbide Products)

Siliconized SiC is a silicon reaction that is uniformly mixed and infiltrated with fine particles of SiC, carbon powder and additives in proportion to generate SiC and combine with SiC, excess silicon fills the gaps to obtain highly dense ceramic materials.

Features:

The material of siliconized silicon carbide has series of basic superiority and characteristic such as high strength, extreme hardness, wear resistance, high temperature tolerance, corrosion resistance, oxidation resistance thermal shock resistance, high thermal conductivity, low coefficient of thermal expansion, creep resistance under high temperature and so on.

Many products can be made from it such as beams, rollers, cooling air pipes, thermal couple protection tubes, temperature-measuring tubes, sealing parts, and special shaped parts.

3. RSiC Products(Recrystallized Silicon Carbide Products)

RSiC Products refer to refractory products made of silicon carbide and silicon carbide directly combined with silicon carbide. They are characterized by the absence of a second phase. They are composed of 100% α-SiC and are new energy-saving kiln furniture materials developed in the 1980s.

Features:

RSiC products are mainly used as kiln furniture, which have the advantages of energy saving, increasing the effective volume of the kiln, shortening the firing cycle, improving the production efficiency of the kiln, and high economic benefits. They can also be used as burner nozzle heads, ceramic radiation heating tubes, component protection tubes (especially for atmosphere furnaces), etc.

4. SiC Products(Oxide Bonded Silicon Carbide Products)

Sintered refractory products with silicon carbide as the main crystal phase and oxide as the bonding phase (silicon dioxide bonded silicon carbide products, mullite bonded silicon carbide products, etc.). Widely used in metallurgy, ceramics, building materials and other industries.

5. NSiC Products(Silicon Nitride Bonded Silicon Carbide Products)

Silicon nitride combined with silicon carbide is a new material, and its main products include silicon nitride combined with silicon carbide radiant tubes, silicon nitride combined with silicon carbide bricks, silicon nitride combined with silicon carbide plates, etc. It is widely used in various industries such as steel, non-ferrous metals, chemical building materials, etc., and has many advantages such as energy saving, environmental protection, high temperature resistance, and corrosion resistance.

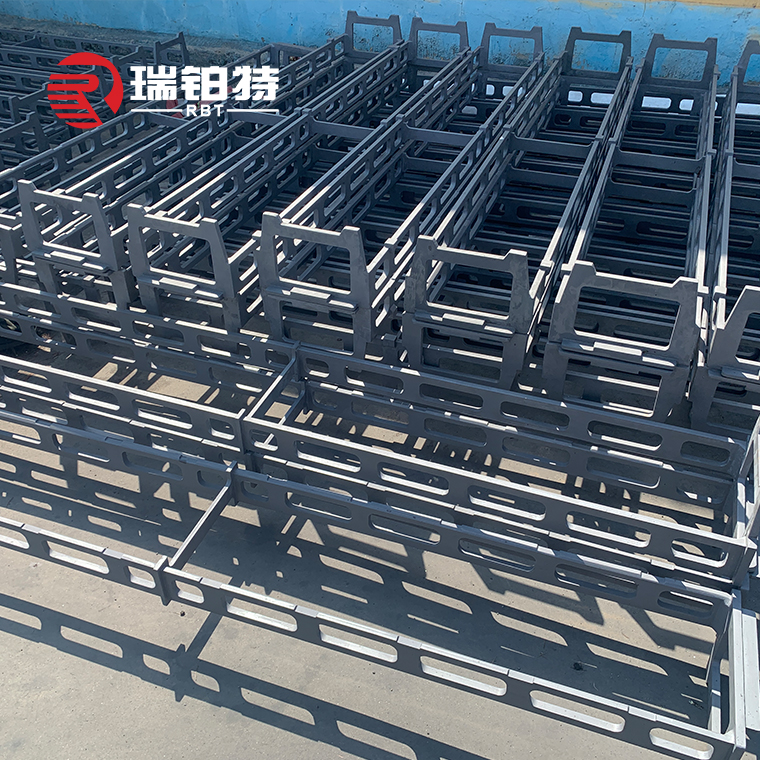

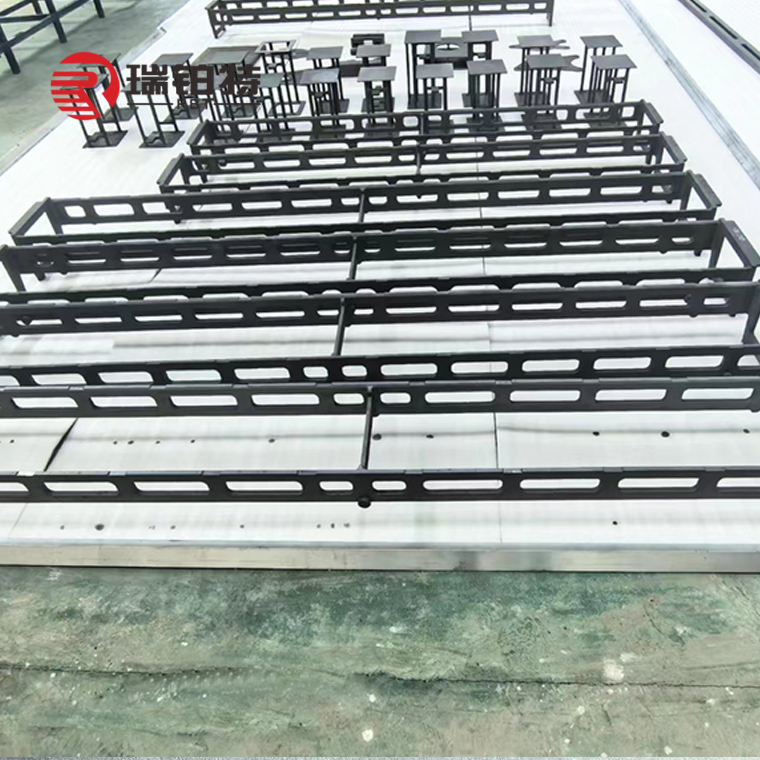

Details Images

For Photovoltaics Industry

Cantilever Paddles

Cantilever Beams

Heating Element Protection Tube

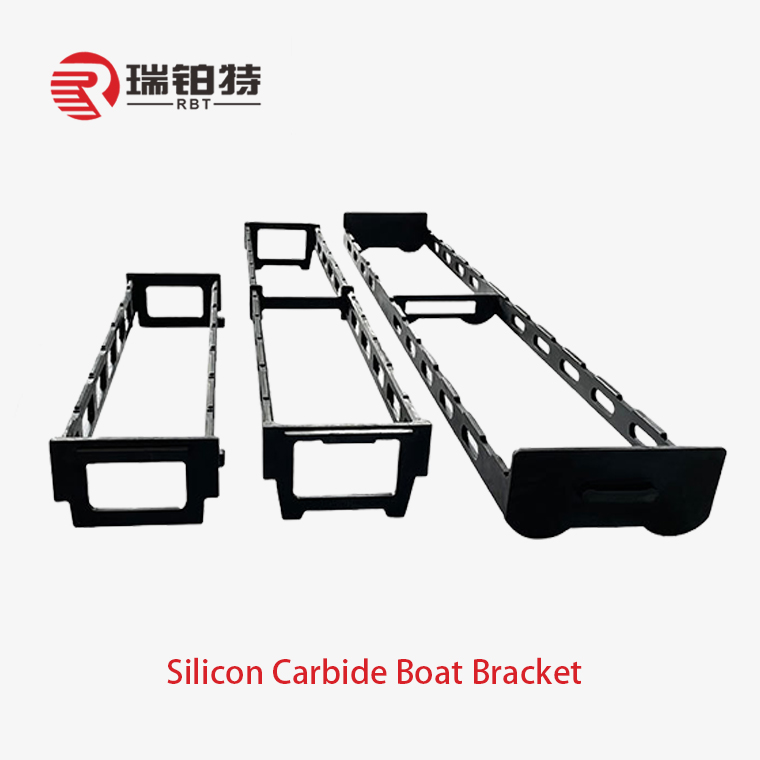

Boat Bracket

Wafer Boat

Temperature Sensor Protection Tube

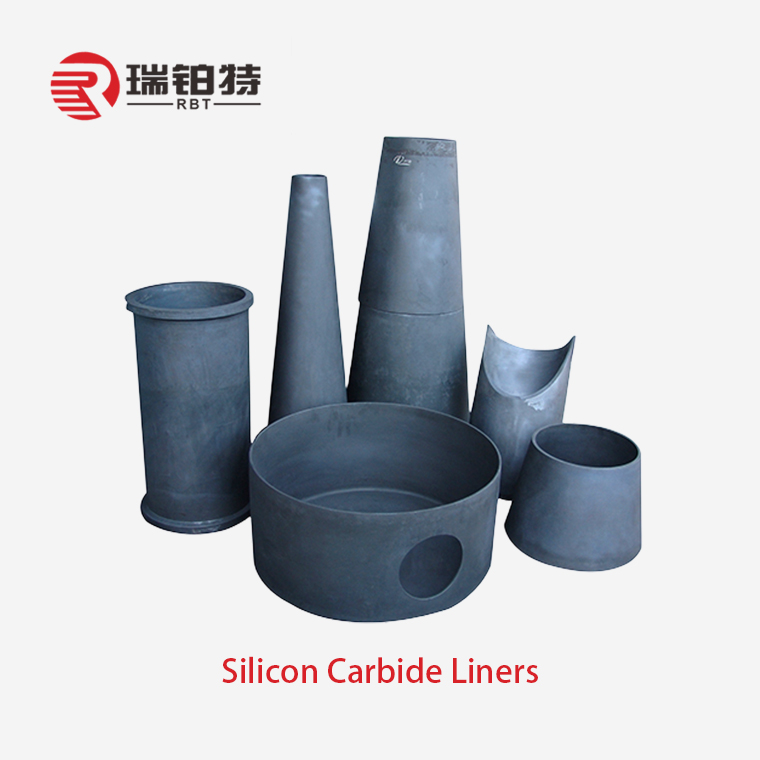

Wear Resistant Products

Silicon Carbide Nozzle

Silicon Carbide Grinding Cylinder

Silicon Carbide Liners

Silicon Carbide Cyclone

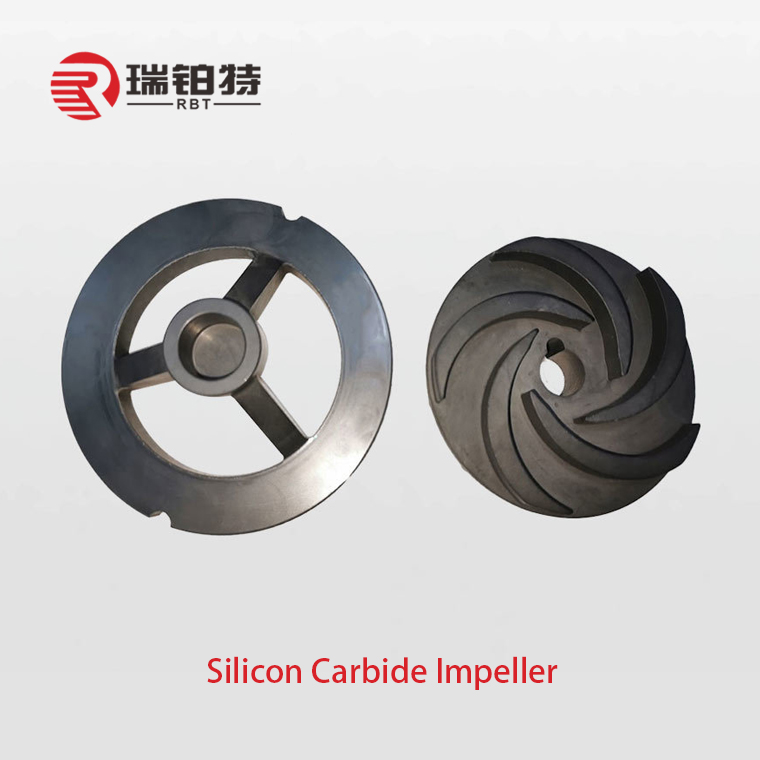

Silicon Carbide lmpeller

Silicon Carbide Seal Ring

High Temperature Resistant Products

Silicon Carbide Heat Radiation Tube

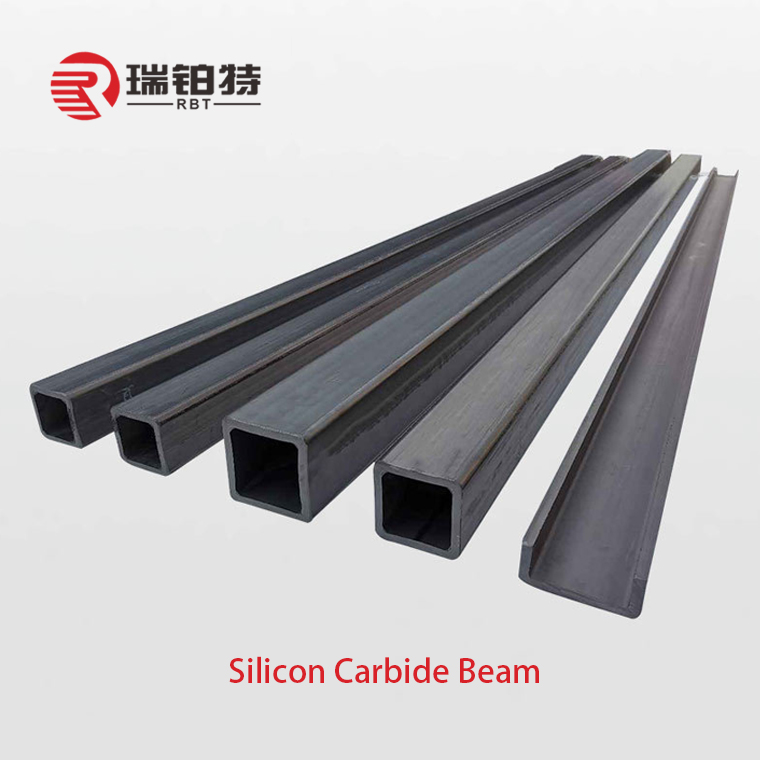

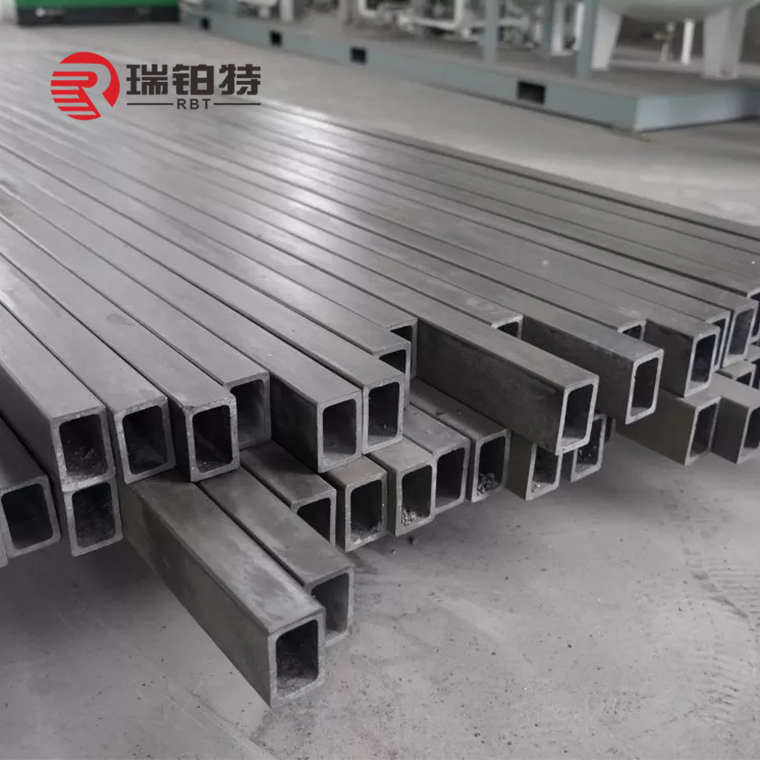

Silicon carbide Beam

Silicon Carbide Saggers And Crucibles

Silicon Carbide Burner Sleeve

Silicon carbide Hanging Burning Rod

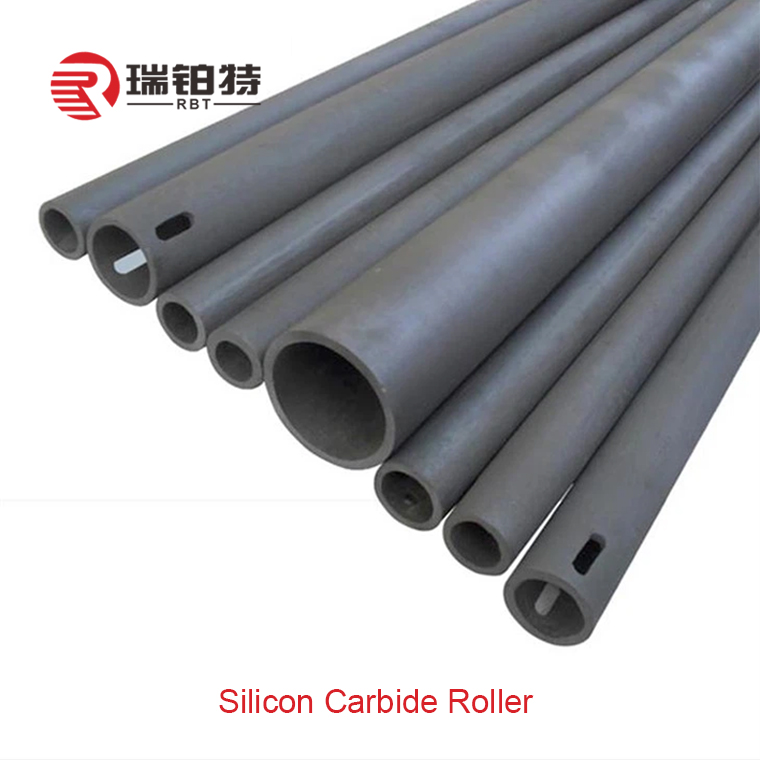

Silicon Carbide Roller

Ion Etching Resistant Products

Silicon Carbide RTA Tray

Silicon Carbide PVD Tray

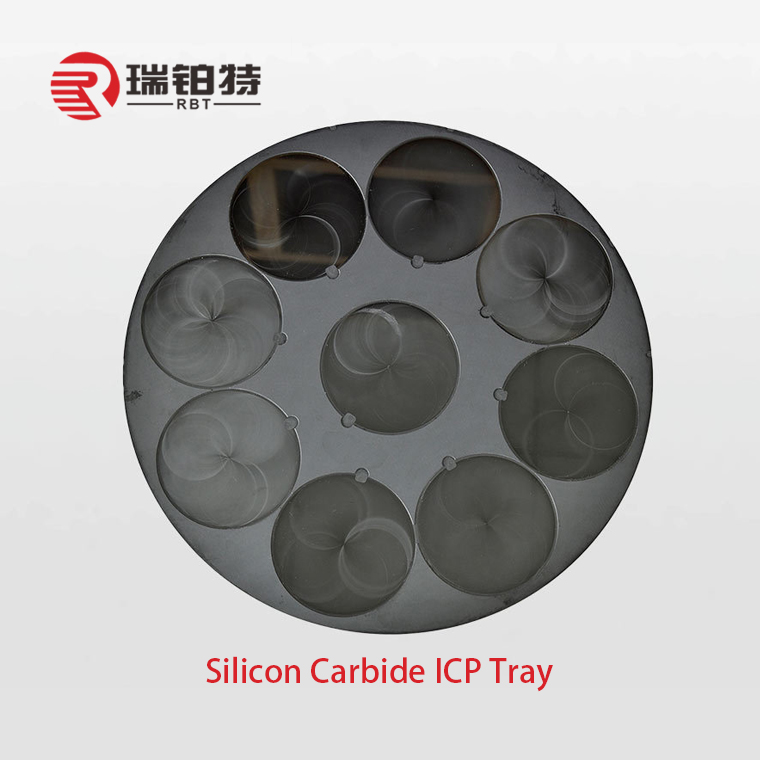

Silicon Carbide ICP Tray

Since there are too many types of silicon carbide products,

we will not list them all here.

If you need customization, please contact us.

Product Index

|

RBSiC(SiSiC) Products

|

||

|

Item

|

Unit

|

Data

|

|

Max Temperature of Application

|

℃

|

≤1380

|

|

Density

|

g/cm3

|

>3.02

|

|

Open Porosity

|

%

|

≤0.1

|

|

Bending Strength

|

Mpa

|

250(20℃); 280(1200℃)

|

|

Modulus of Elastictiy

|

Gpa

|

330(20℃); 300(1200℃)

|

|

Thermal Conductivity

|

W/m.k

|

45(1200℃)

|

|

Thermal Expansion Coefficient

|

K-1*10-6

|

4.5

|

|

Moh's Hardness

|

|

9.15

|

|

Acid Alkaline-Proof

|

|

Excellent

|

|

SSiC Products

|

||

|

Item

|

Unit

|

Result

|

|

Hardness

|

HS

|

≥115

|

|

Porosity Rate

|

%

|

<0.2

|

|

Density

|

g/cm3

|

≥3.10

|

|

Compressive Strength

|

Mpa

|

≥2500

|

|

Bending Strength

|

Mpa

|

≥380

|

|

Coefficient of Expansion

|

10-6/℃

|

4.2

|

|

Content of SiC

|

%

|

≥98

|

|

Free Si

|

%

|

<1

|

|

Elastic Modulus

|

Gpa

|

≥410

|

|

Temperature

|

℃

|

1400

|

Application

Photovoltaic - Mainly used in the thermal process and coating process of solar cells;

Applicable Products: Cantilever Paddles; Cantilever Beam; Boat Bracket; Wafer Boat, etc

Suitable for precision ceramic structural parts used in semiconductor equipment.

Suitable for ICP etching process, PVD process, RTP process, CMP process and other precision ceramic structural parts in the manufacture of optoelectronic lighting epitaxial wafers.

Heat exchange tubes, block holes, and heat exchange plates made of silicon carbide are suitable for cooling, condensing, heating, evaporating, thin film evaporating, and absorbing equipment for highly corrosive chemicals.

Rollers and beams made of silicon carbide are widely used in sintering furnaces for positive and negative electrode materials of lithium batteries. Silicon carbide wear-resistant parts with extremely high hardness and strength can also be used in powder processing equipment such as sand milling and dispersion of lithium battery materials.

Suitable for making the core components of microchannel continuous flow chemical reactors /equipment: reaction tubes, reaction plates and reaction plate modules. Silicon carbide microchannel reactors can be applied to a wider range of chemical reactions.

More Images

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.