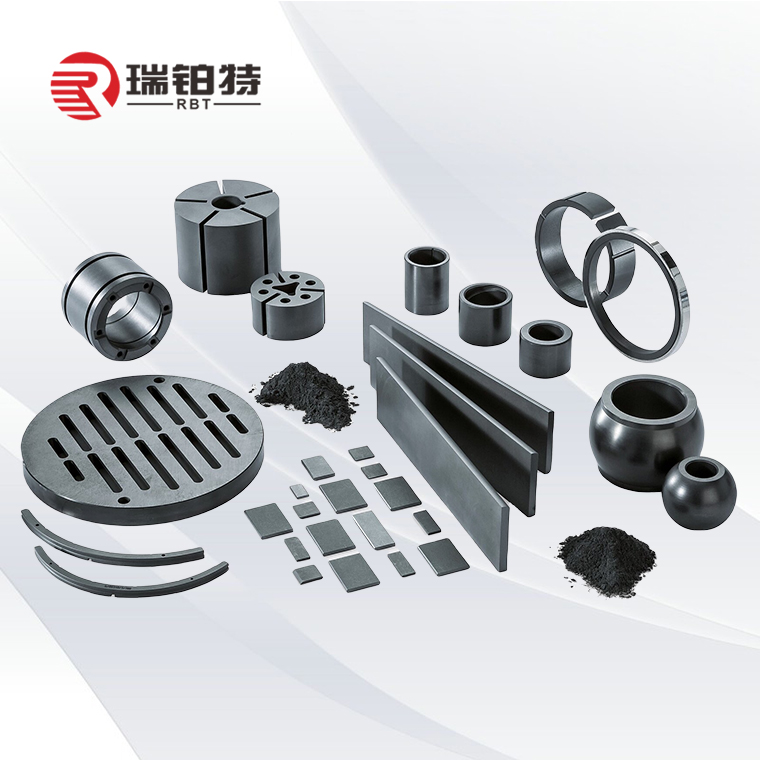

SSiC Products

Product Information

|

Product Name

|

SSIC Products(Atmospheric Sintering Silicon Carbide Products)

|

|

Description

|

1. This material is a dense SiC ceramic product made by pressureless sintering of high performance sub-micron SiC powder. It does not contain free silicon and has fine grains. 2. It is currently the preferred general material for the international and domestic manufacturing of mechanical seal rings, sandblasting nozzles, bulletproof armor, magnetic pumps, and canned pump components. 3. It is especially suitable for use in the transportation of corrosive media such as strong acids and strong alkali. |

|

Feature

|

1. High strength, high hardness, wear resistance, density up to 3.1kg/m3.

2. High attenuation performance, low thermal expansion, high thermal shock resistance, high temperature creep resistance. 3. Chemical stability, corrosion resistance, especially hydrofluoric acid resistance. 4. High-temperature resistance, maximum operating temperature up to 1380 ℃. 5. Long service life and reduce overall investment cost. |

Product Index

|

SSiC Products

|

||

|

Item

|

Unit

|

Result

|

|

Hardness

|

HS

|

≥115

|

|

Porosity Rate

|

%

|

<0.2

|

|

Density

|

g/cm3

|

≥3.10

|

|

Compressive Strength

|

Mpa

|

≥2500

|

|

Bending Strength

|

Mpa

|

≥380

|

|

Coefficient of Expansion

|

10-6/℃

|

4.2

|

|

Content of SiC

|

%

|

≥98

|

|

Free Si

|

%

|

<1

|

|

Elastic Modulus

|

Gpa

|

≥410

|

|

Temperature

|

℃

|

1400

|

Details Images

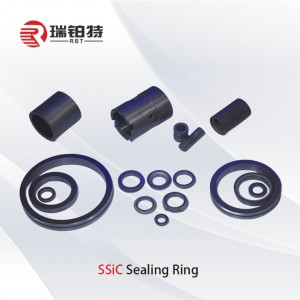

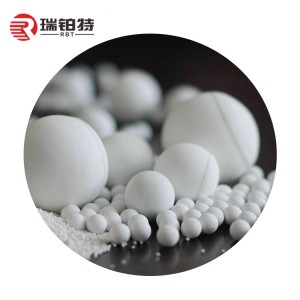

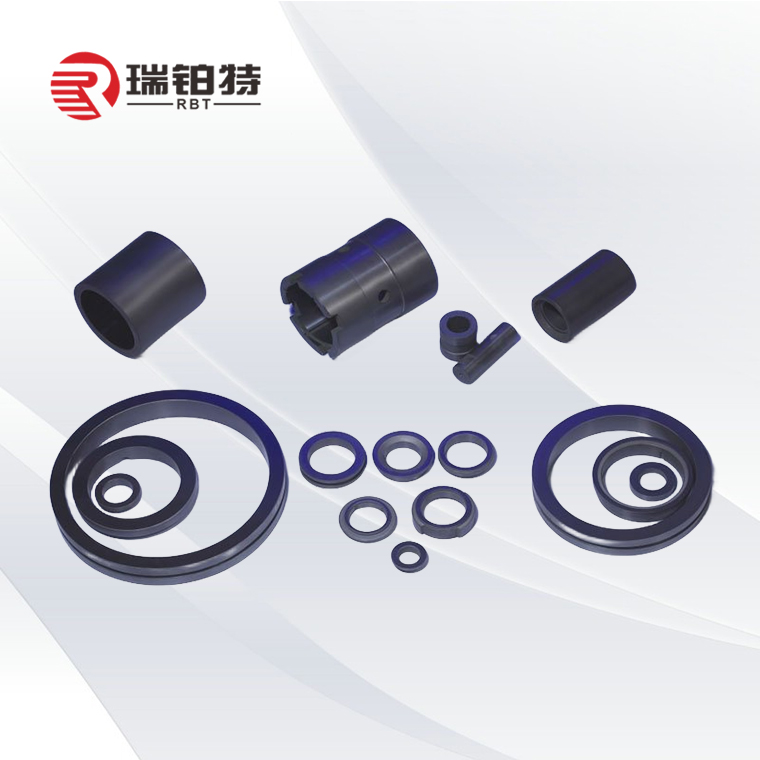

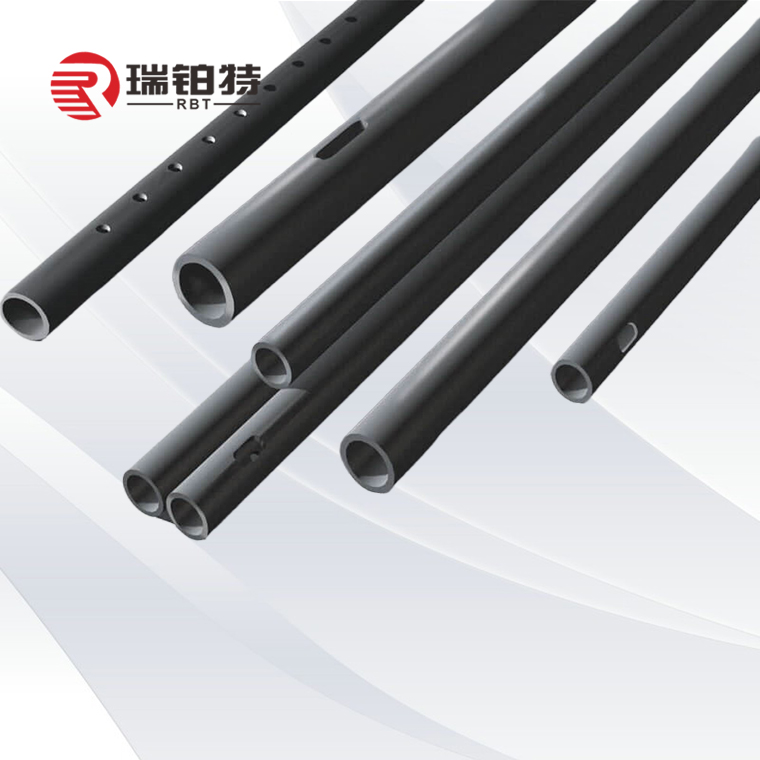

SSiC Sealing Ring

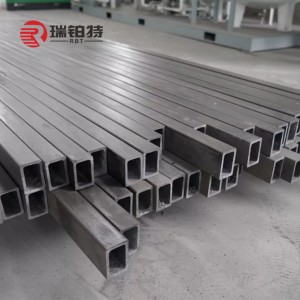

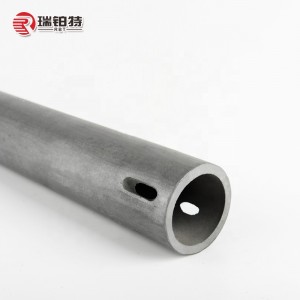

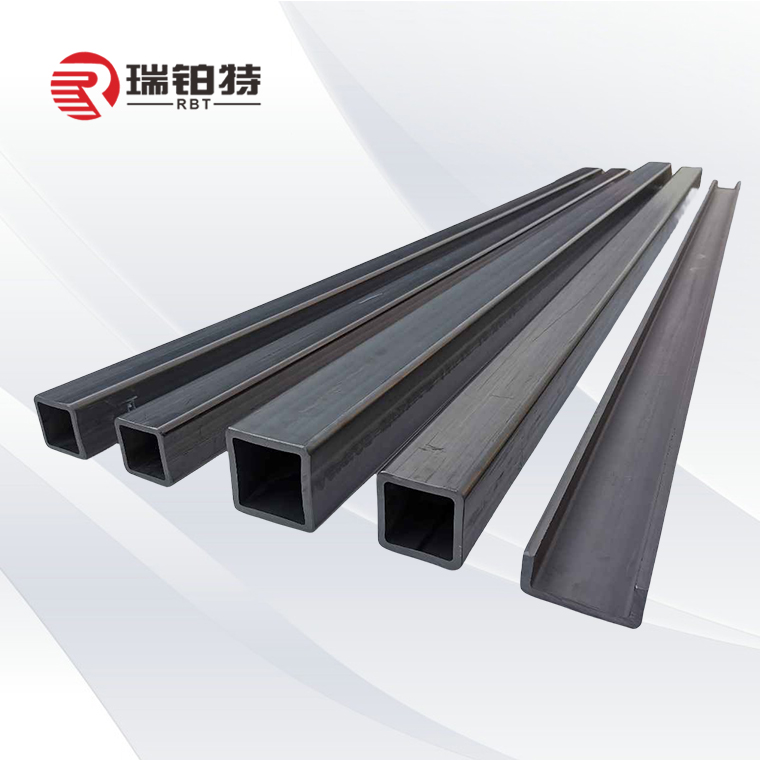

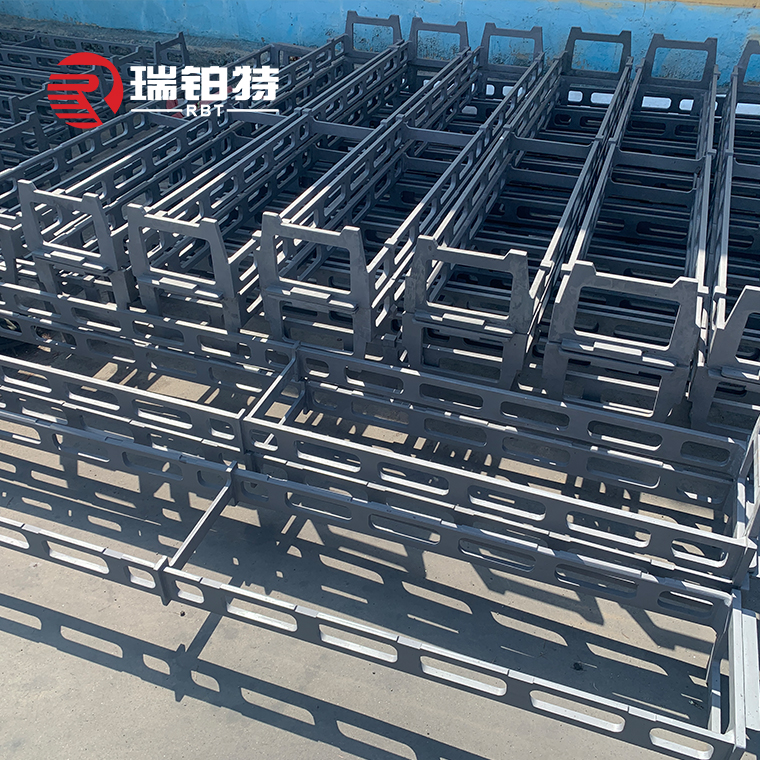

SSiC Beams

SSiC Tray

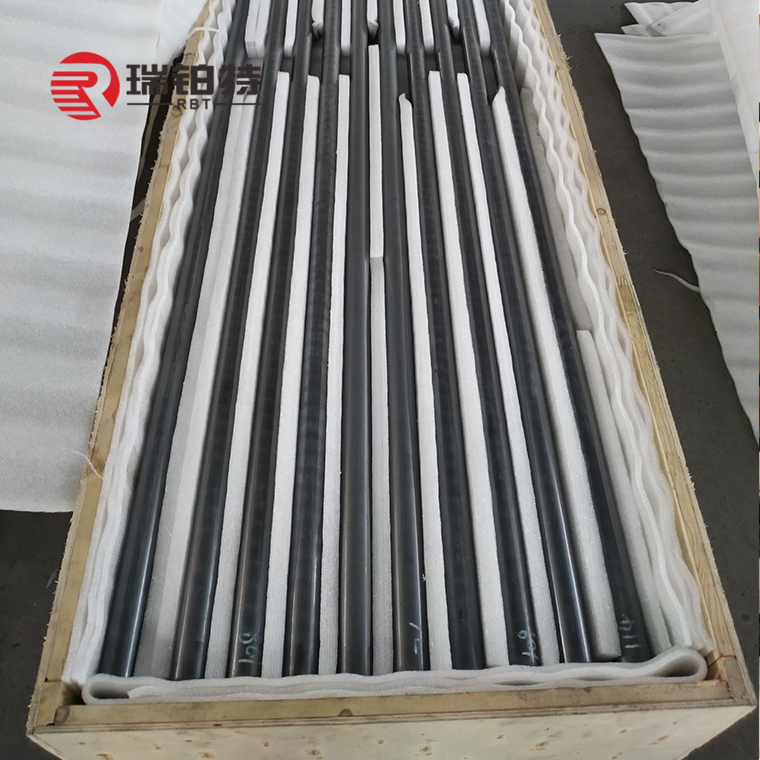

SSiC Roller

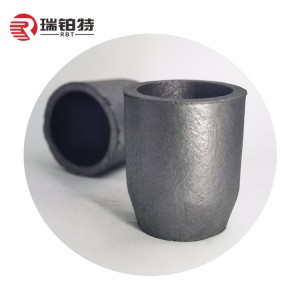

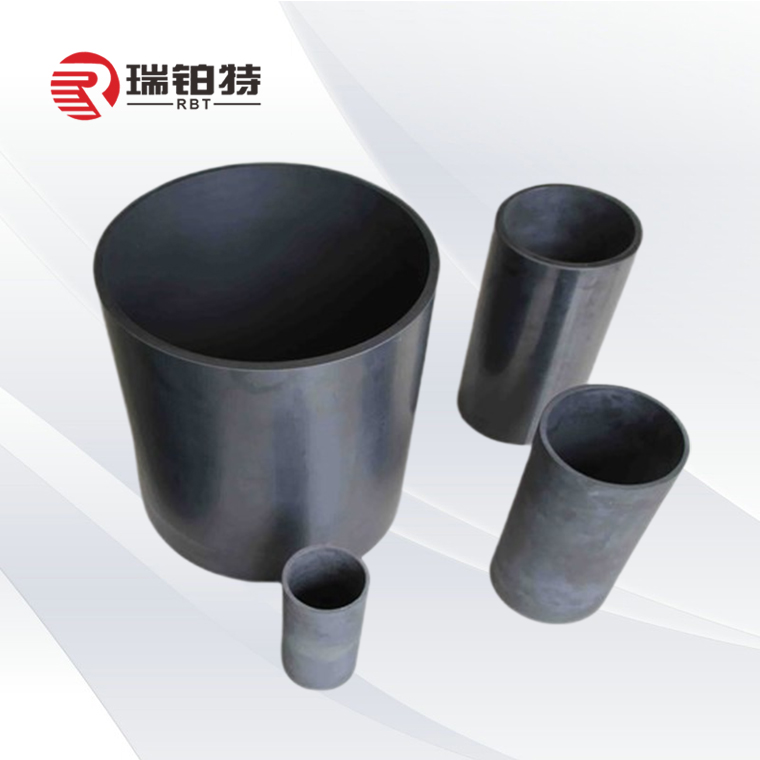

SSiC Grinding Barrel

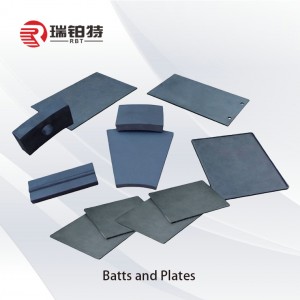

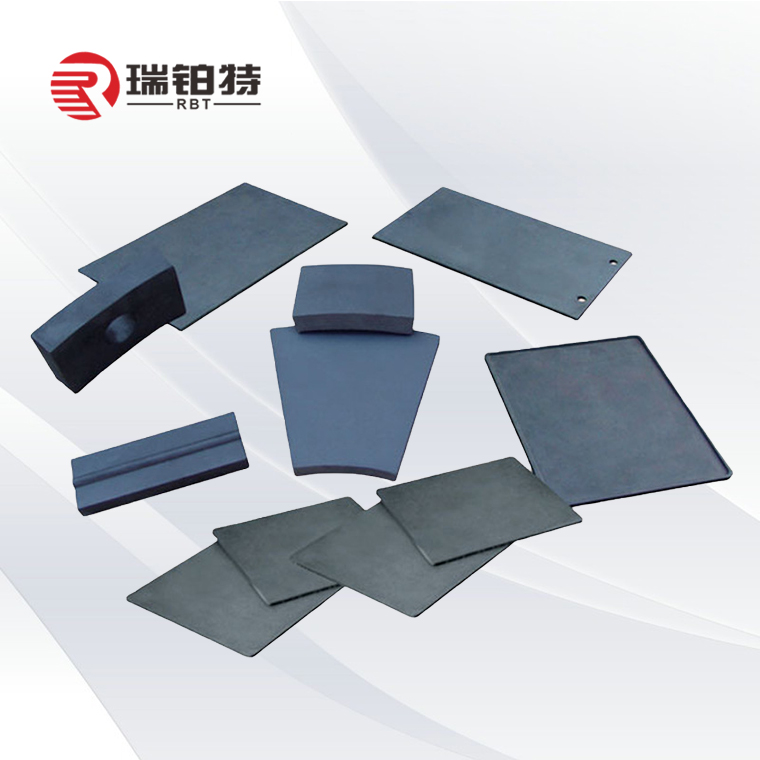

SSiC Batts and Plates

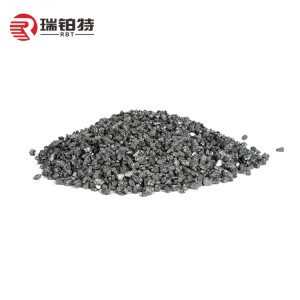

SSiC Customized Shaped Parts

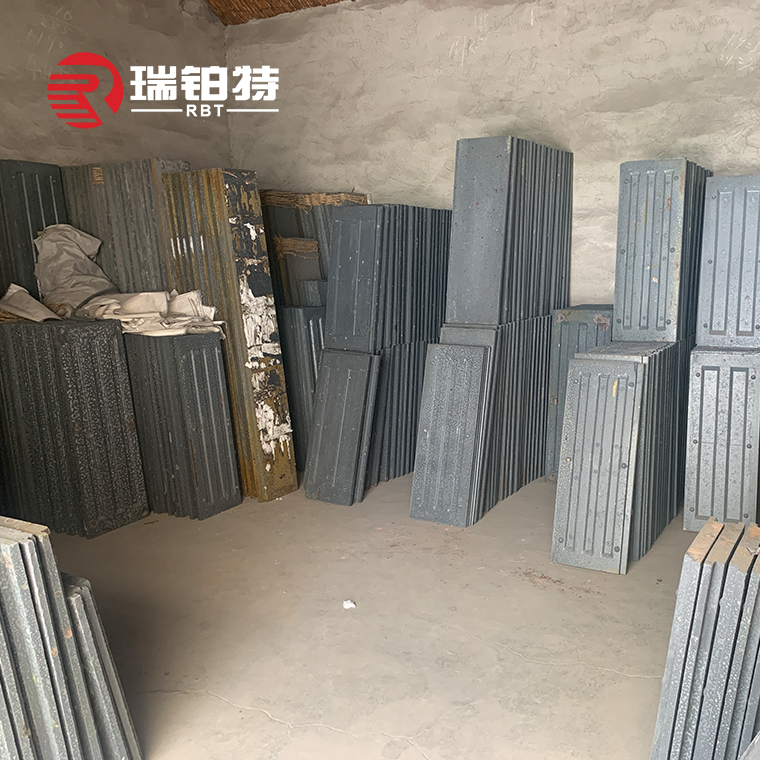

Package&Warehouse

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.