Silicon Nitride Thermocouple Protection Tube

Product Information

Silicon nitride thermocouple protection tube is a high-performance protection tube material, mainly used for temperature measurement in harsh environments such as high temperature and strong corrosion.

Features:

High temperature stability: Silicon nitride material has excellent high temperature stability, can maintain its structural stability and integrity in high temperature environment, and ensure the normal operation of thermocouple.

Chemical stability: Silicon nitride material has good chemical stability, can resist the erosion of many strong acids, strong alkalis and other chemical substances, and protect thermocouples from chemical corrosion.

High strength and high hardness: This makes the protection tube have good impact resistance and wear resistance, and can maintain its long service life in harsh working environments.

Good insulation performance: Silicon nitride material has good insulation performance, which can effectively prevent the thermocouple from being affected by electromagnetic interference during operation and ensure measurement accuracy.

Excellent thermal conductivity: The tube wall is thin (only a few millimeters), and the temperature response is very fast. The temperature of the molten metal can be measured within 1 minute.

Strong anti-corrosion ability: Corrosion-resistant, erosion-resistant, not easy to accumulate slag, and easy to maintain.

Long service life: The service life is more than 12 months, and it can be used for several years at most, with a very high cost performance.

Details Images

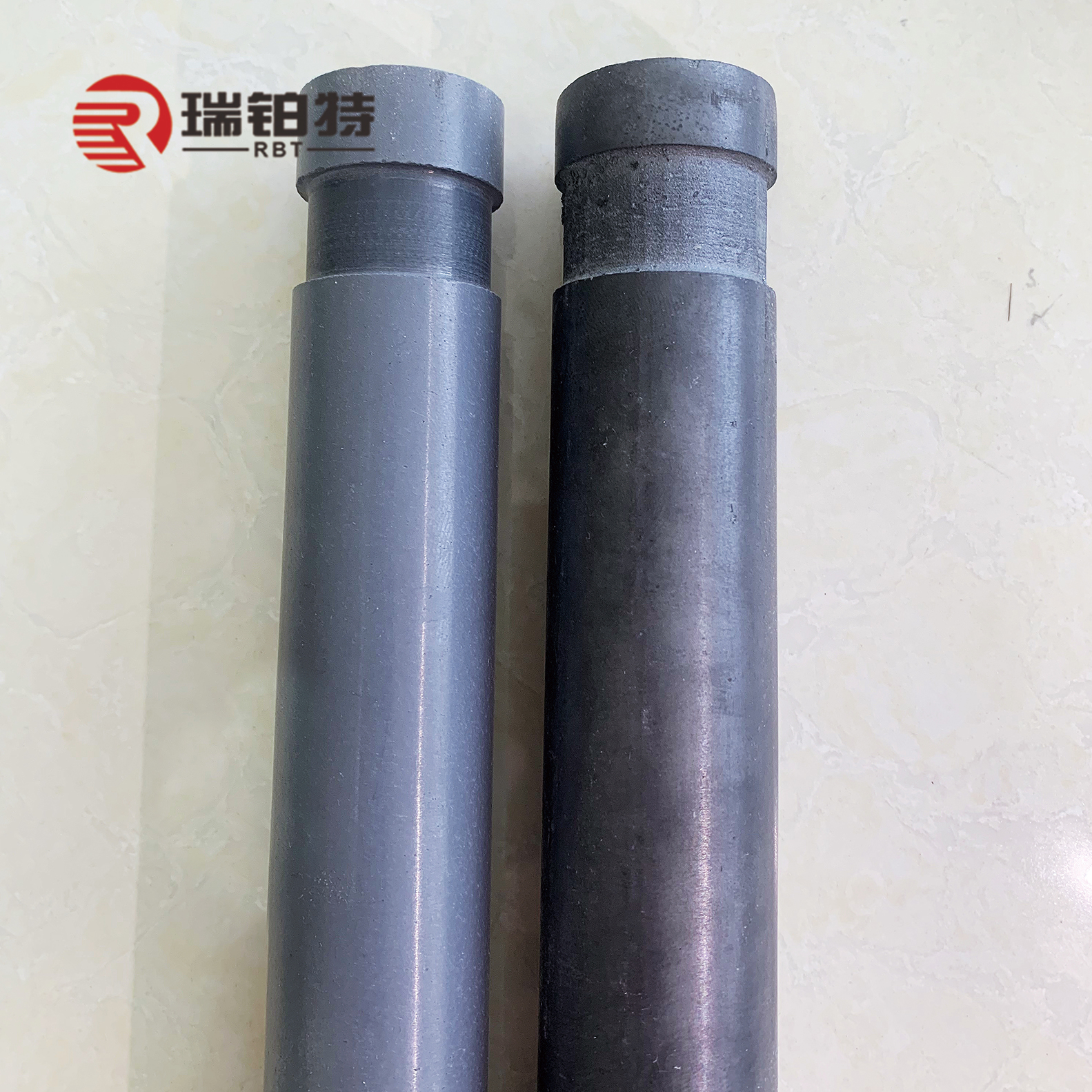

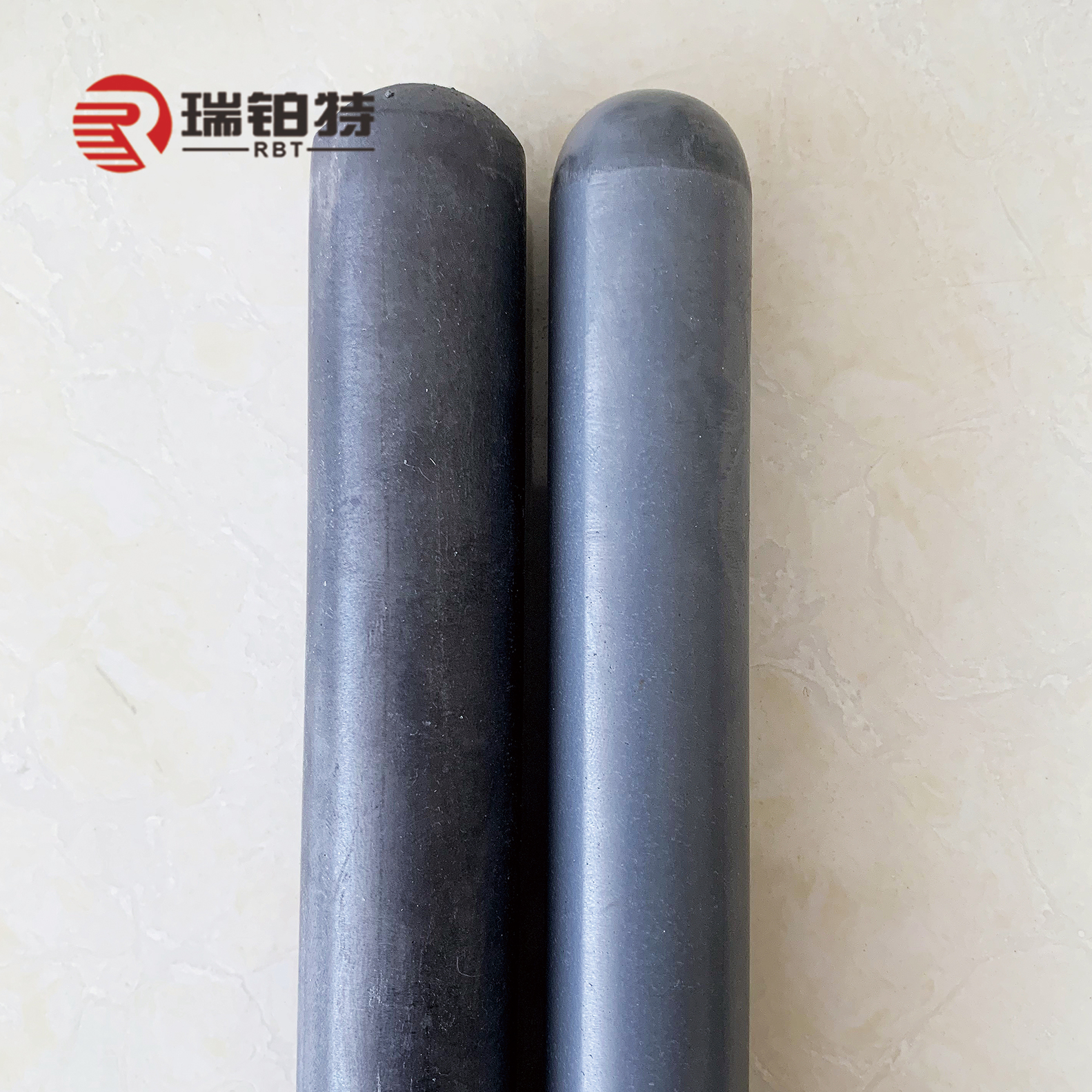

Difference Between Black and White

Silicon nitride thermocouple protection tubes are available in black and white. Black silicon nitride thermocouple protection tubes are usually used in high temperature environments, have good thermal conductivity and thermal shock resistance, and can remain stable at high temperatures. White silicon nitride thermocouple protection tubes are mainly used in situations where high insulation is required, and have good insulation performance and electrical corrosion resistance.

Reasons for color differences

Manufacturing process: Black and white silicon nitride thermocouple protection tubes may use different processing processes during the manufacturing process. For example, the black protection tube may have undergone special surface treatment or added certain additives, while the white protection tube may have a different formulation or treatment method.

Specific application scenarios

Black silicon nitride thermocouple protection tubes: Commonly used in high temperature environments, such as crystalline silicon reduction furnaces, low-pressure aluminum casting/casting, papermaking and other industries. These occasions require the protection tube to have good thermal conductivity, thermal shock resistance and corrosion resistance.

White silicon nitride thermocouple protection tubes: Suitable for situations where high insulation is required, such as insulation protection of components such as bearings. These occasions require the protective tube to have good insulation and resistance to electrical corrosion.

Product Index

|

Density

|

3.20+0.04g/cm3

|

|

Apparent Porosity

|

<0.3%

|

|

Elastic Modulus

|

300-320GPa

|

|

Compression Strength Ratio

|

35-45%(25℃)

|

|

Hardness(HRA)

|

92-94Gpa

|

|

Fracture Toughness

|

7.0-9.0/Mpa.m1/2

|

|

Bending Strength

|

800-1000MPa

|

|

Poisson's Ratio

|

0.25

|

|

Webuller Modulus

|

11-13

|

|

Thermal Conductivity

|

22-24w.(m.k)-1

|

|

Corrosion Resistance

|

Good

|

|

Size Stability

|

Good

|

Application

Petrochemical Industry: In the petrochemical industry, silicon nitride thermocouple protection tubes can withstand high temperatures and chemical corrosion, ensure the accuracy of temperature measurement, and are suitable for various chemical reaction processes.

Steel Smelting: In the steel smelting process, high temperature and strong corrosion are the norm. Silicon nitride protection tubes can provide reliable protection to ensure accurate temperature control during the smelting process.

Ceramic Production: Ceramic production requires a high-temperature firing process. Silicon nitride protection tubes can withstand high temperatures, protect thermocouples from damage, and ensure product quality.

Glass Manufacturing: Temperature control is required during glass manufacturing. Silicon nitride protection tubes can work stably in high temperature and corrosive environments to ensure the accuracy of temperature measurement.

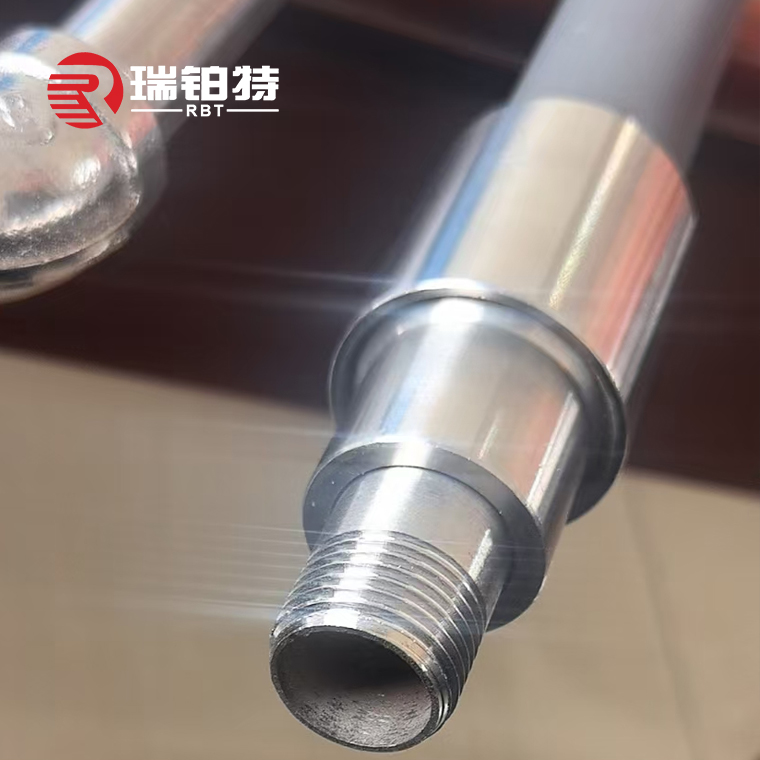

More Details

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.