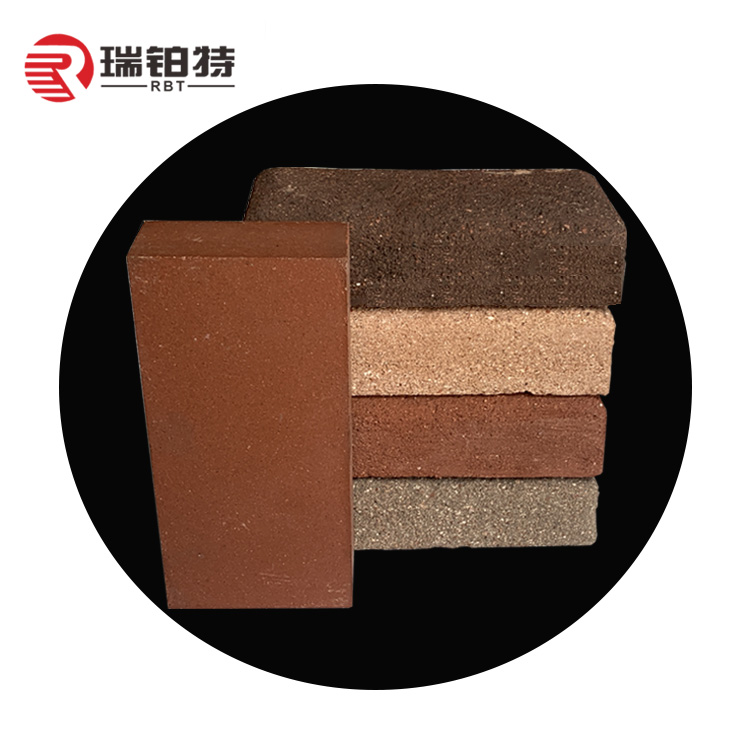

Sintered Pavement Bricks

description

Sintered pavement bricks are different from other bricks in that they are made using a special production process. It is produced by fire. This also means that during production, there are high requirements for the overall temperature control and time, so as to produce better quality sintered bricks.

Features

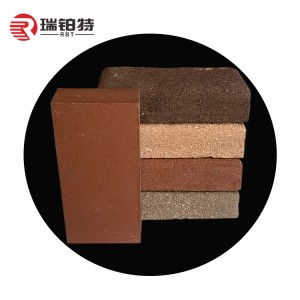

1. The appearance is simple and elegant, without fading, and the natural color difference produced during the calcination process is very simple and natural, giving people a soft and beautiful feeling;

2. The cut surface forms a natural texture, and the overall color of the brick surface of the fired brick is the same, even after many years of use, it still maintains the true color;

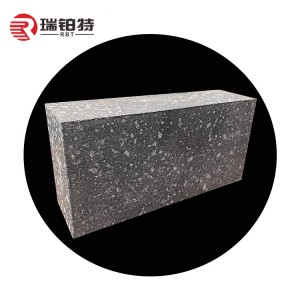

3. The internal quality is excellent. It is fired with a vacuum extruder combined with modern external combustion technology. The compressive strength reaches > 70Mpa, the water absorption rate < 8%, and the freeze-thaw resistance is excellent;

4. Non-slip, wear-resistant, no radiation, no pollution;

5. After the sintered brick is sintered at 1200 degrees Celsius, the internal particles are melted to improve its wear resistance, and there is no powder or dust after being rolled by a vehicle, which is a green and environmentally friendly building material.

Cleaning And Maintenance

1. You can use decontamination powder, stain remover paste, car wax, etc. to remove black scratches, oil stains, rust spots, etc. caused by ironware, and use a clean cheesecloth to wipe back and forth until dry;

2. The daily cleaning of sintered bricks is mainly in a dry position, using cleaning tools to clean the fine sand, gravel, dust, dirt, etc. on the surface, and then wipe with a clean rag or mop dampened with water.