Silicon Carbide Cantilever Paddles

Product Categories

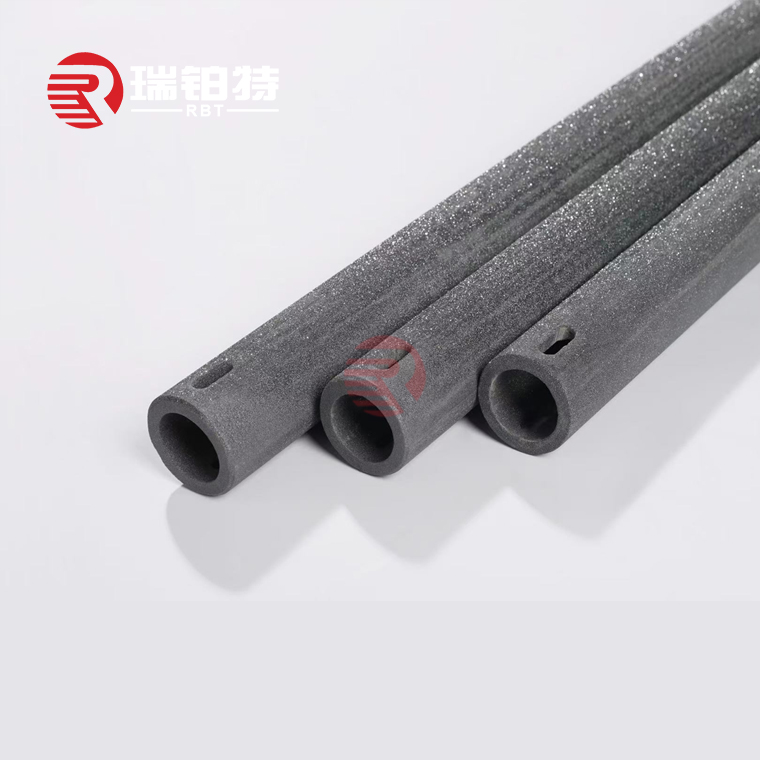

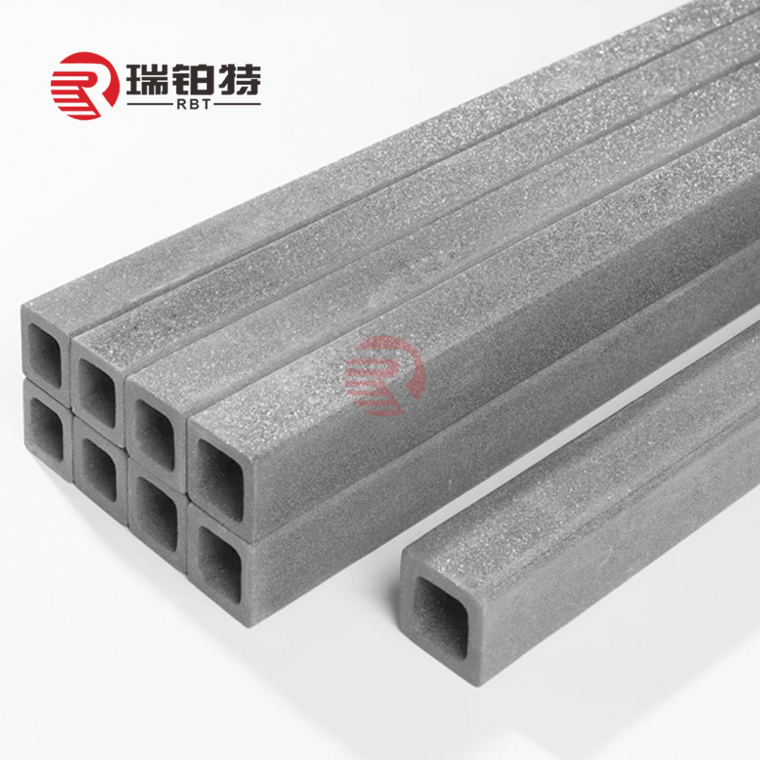

1. Reaction sintered silicon carbide products(RBSiC Products)

Reaction bonded silicon carbide (RBSiC) is an advanced engineering ceramic material that generates a silicon carbide bonding phase by reacting free carbon with liquid silicon under high temperature conditions. Its basic components include silicon carbide (SiC) matrix and free silicon (Si). The former provides excellent mechanical properties, wear resistance and high temperature stability,

while the latter fills the pores between silicon carbide particles to enhance the density and structural integrity of the material.

(1) Characteristics:

High temperature stability: Maximum operating temperature 1350℃.

Wear resistance and corrosion resistance: Suitable for harsh working conditions of high temperature, acid, alkali and molten metal.

High thermal conductivity and low thermal expansion coefficient: The thermal conductivity is as high as 120-200 W/(m·K), and the thermal expansion coefficient is only 4.5×10⁻⁶ K⁻¹, which effectively prevents thermal cracking and thermal fatigue.

Anti-oxidation: A dense silica protective layer is generated on the surface at high temperature to extend the service life.

(2) Main Products:

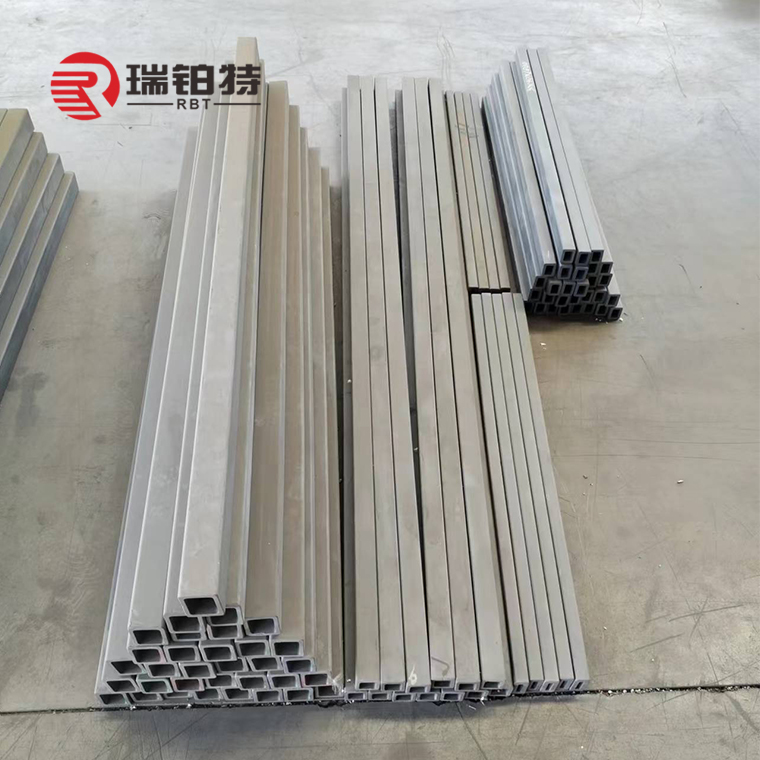

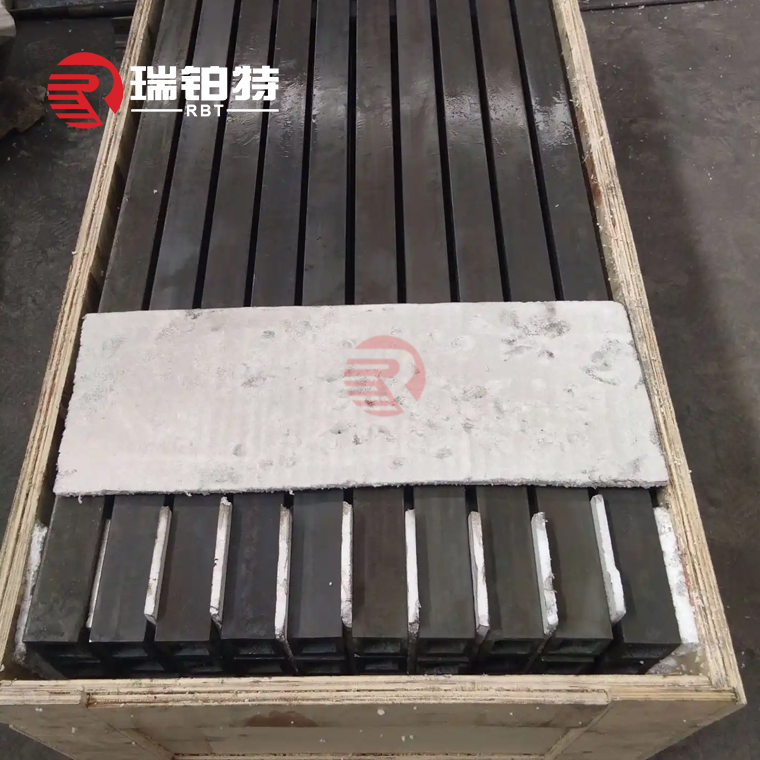

Silicon carbide beam: used for the load-bearing structure of tunnel kilns, shuttle kilns and other industrial kilns, with excellent high temperature resistance.

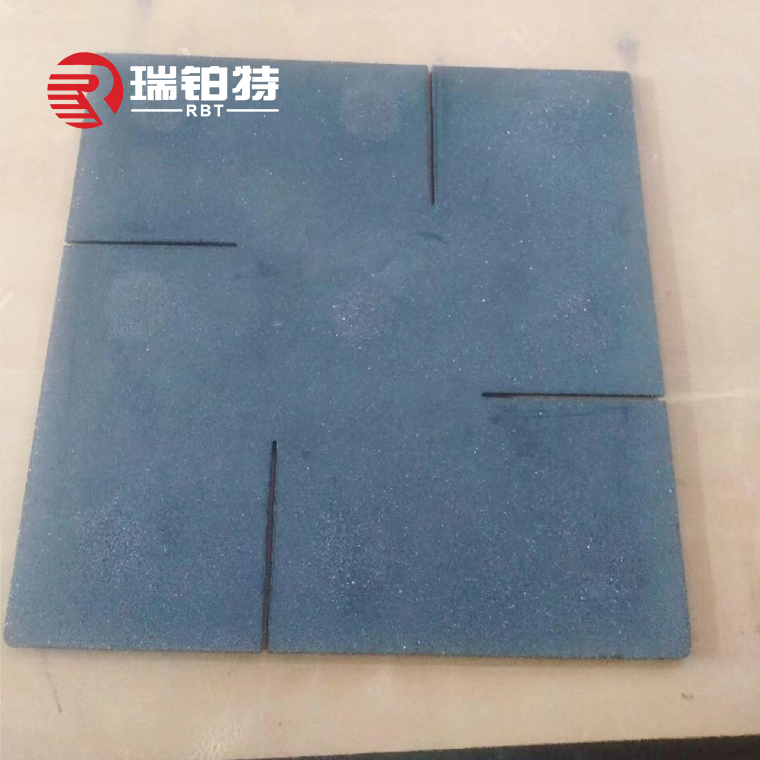

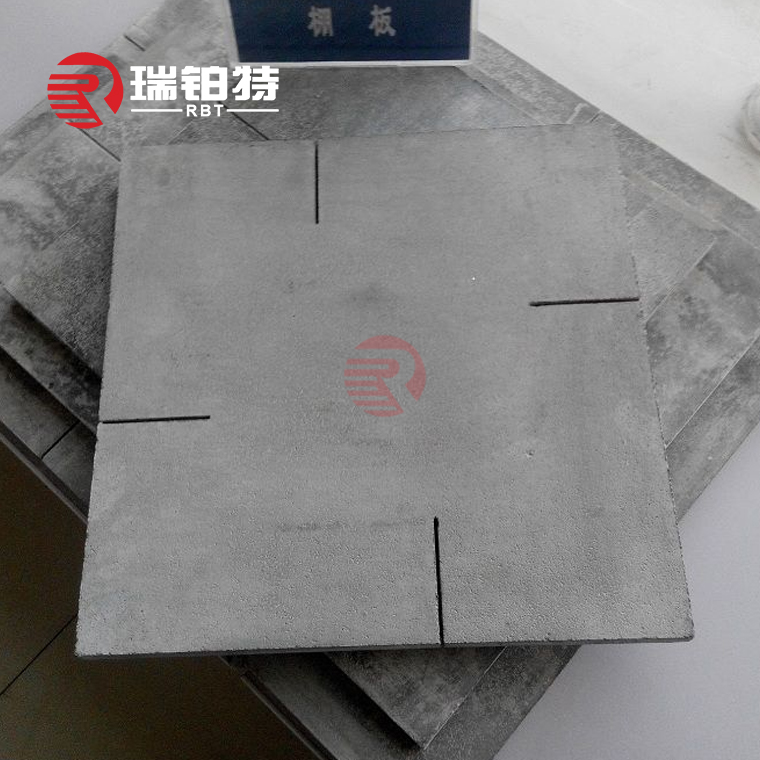

Silicon carbide plate: used for refractory materials in kilns, with the characteristics of oxide bonding.

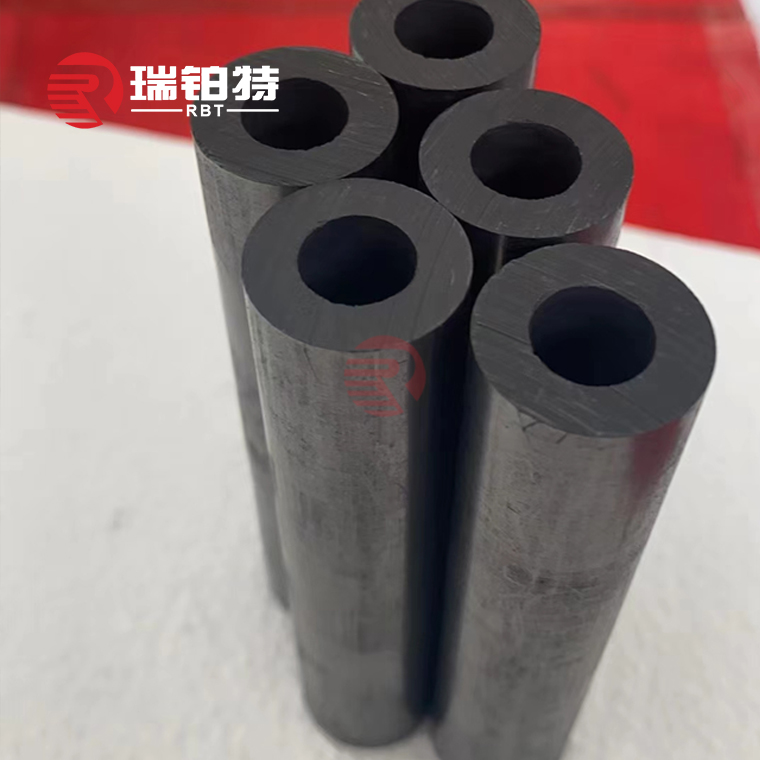

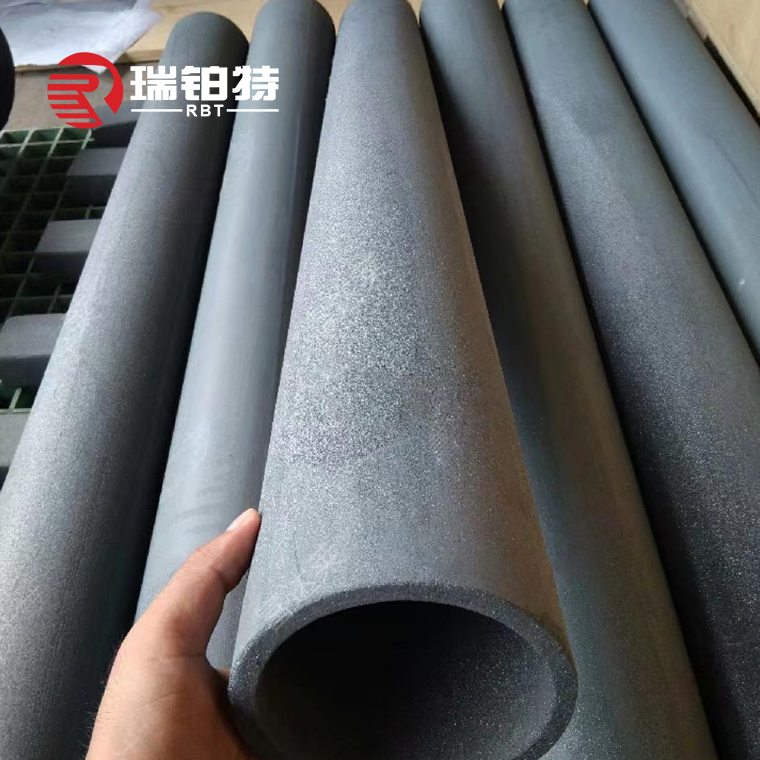

Silicon carbide pipe: used for pipes and containers in various high temperature environments.

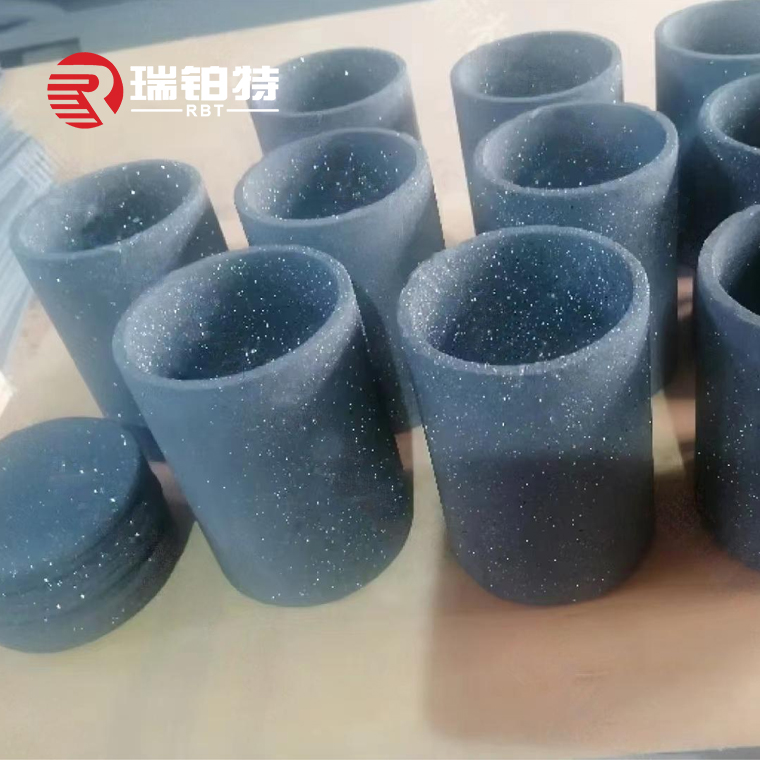

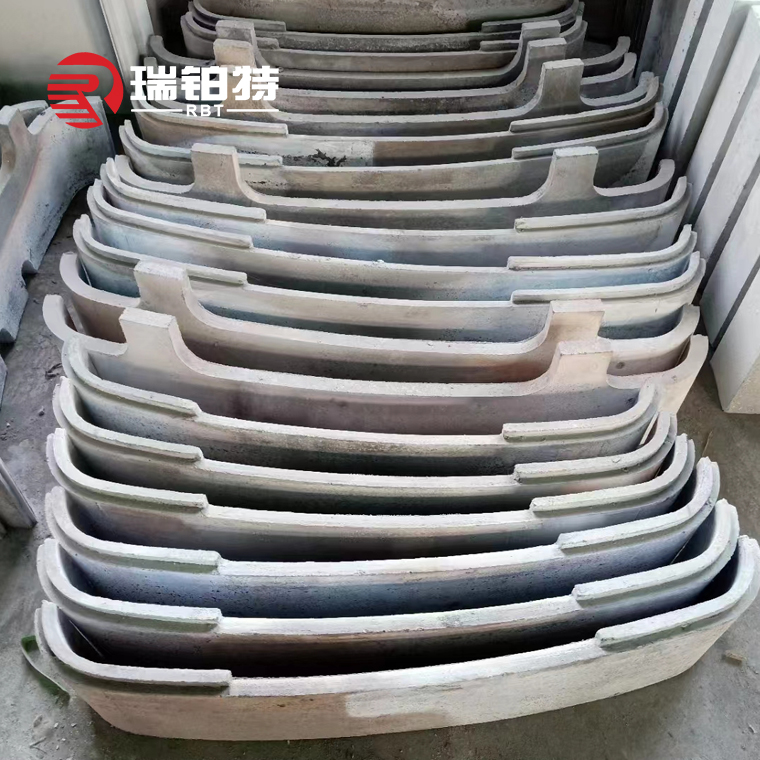

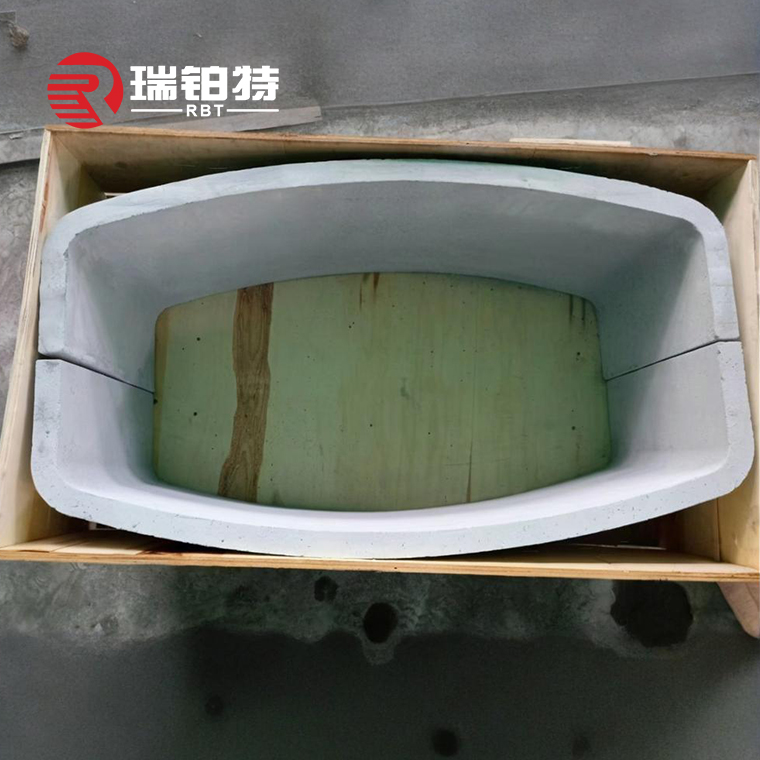

Silicon carbide crucible and sagger: used for high temperature smelting and storage of materials.

Silicon carbide seal ring: widely used in the fields of automobiles, aerospace and chemical industry, and can maintain reliable sealing performance in high temperature and high pressure environments.

Silicon carbide roller: used for roller kilns, with the characteristics of anti-oxidation, high temperature flexural strength and long service life.

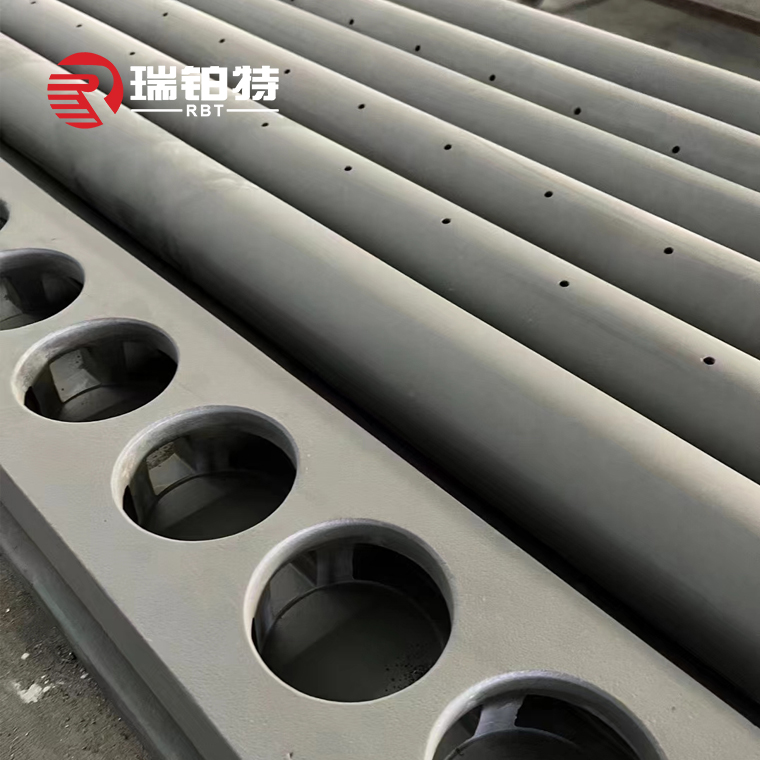

Silicon carbide cooling pipes: used for the cooling zone of roller kilns, with good resistance to extreme

cold and heat.

Silicon carbide bunner nozzle: used for various oil, gas and other industrial kilns, with the characteristics of extreme cold and heat resistance, wear resistance, high temperature resistance, etc..

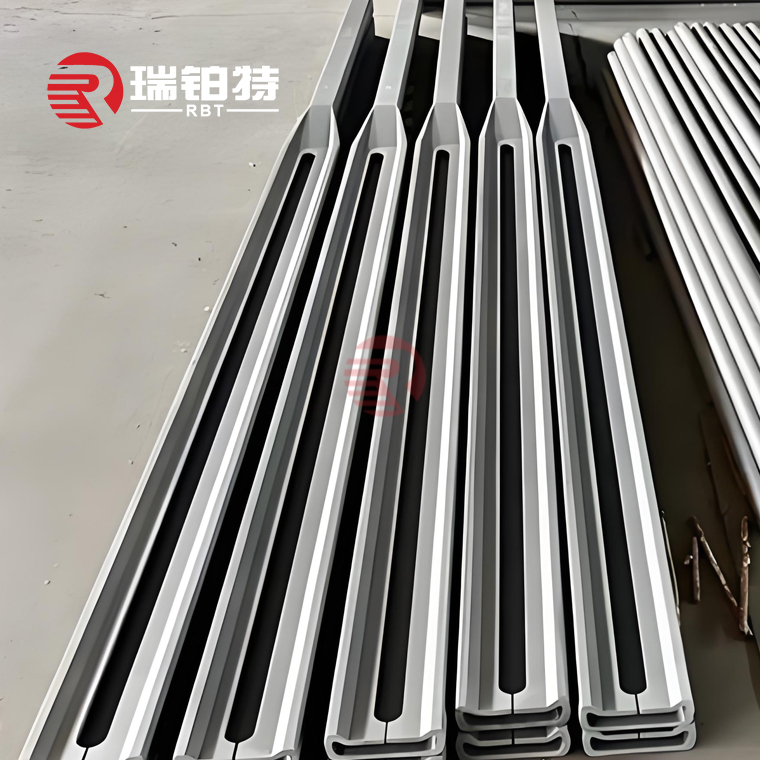

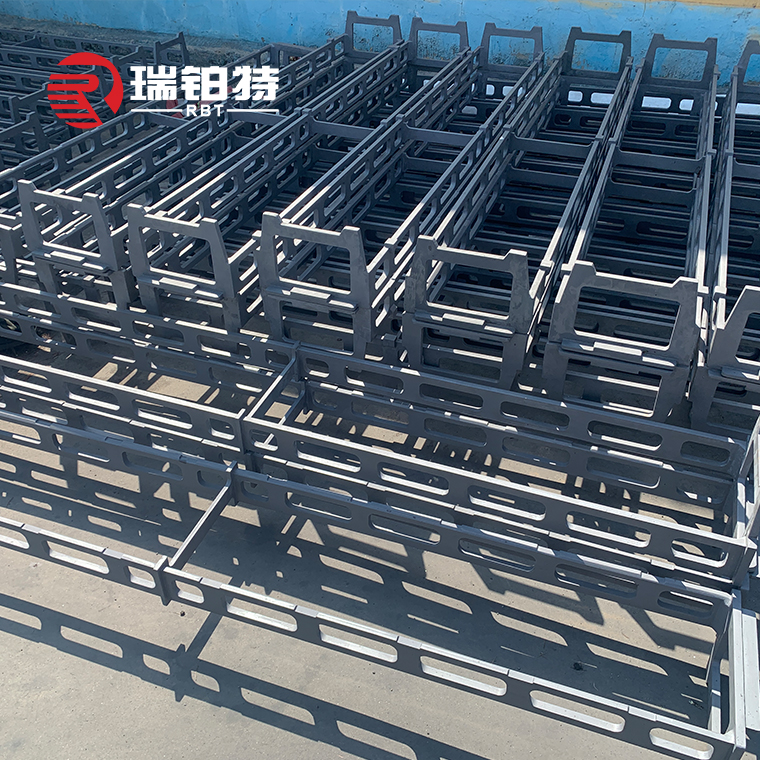

Customized special-shaped parts: Customized production of various special-shaped parts according to customer needs, such as fish-shaped plates, hanging rods, support parts, etc.

Details Images

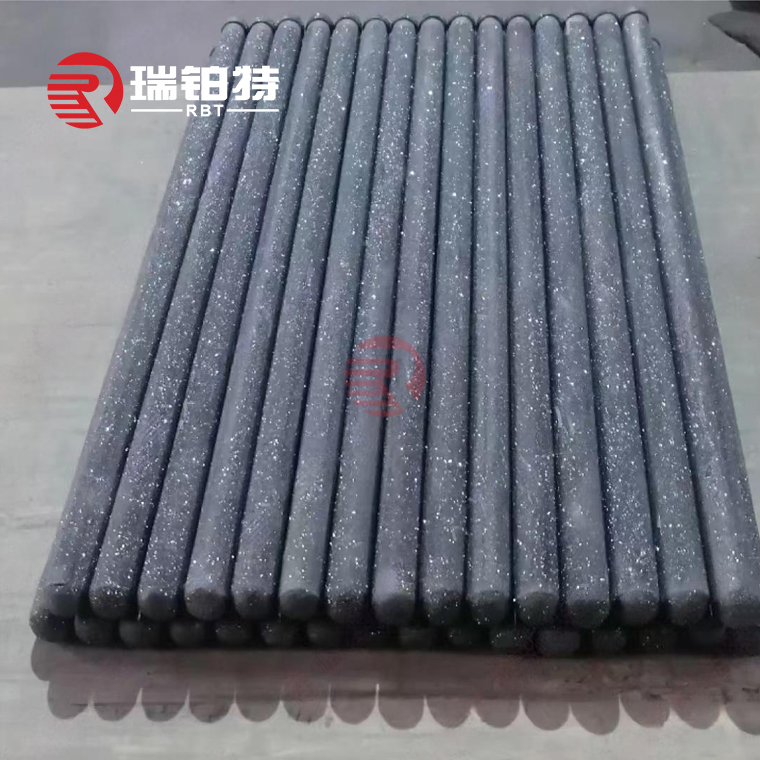

Silicon Carbide Beam

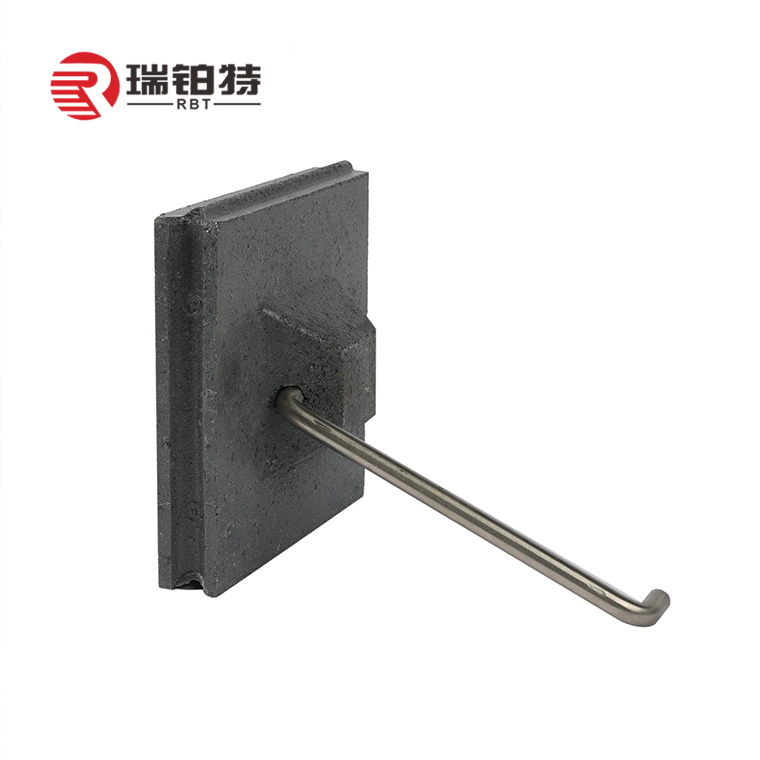

Silicon Carbide Cantilever Paddle

Silicon Carbide Nozzle

Silicon Carbide Burner Tube

Silicon Carbide Cooling Pipes

Silicon Carbide Nozzle

Silicon Carbide Boat Bracket

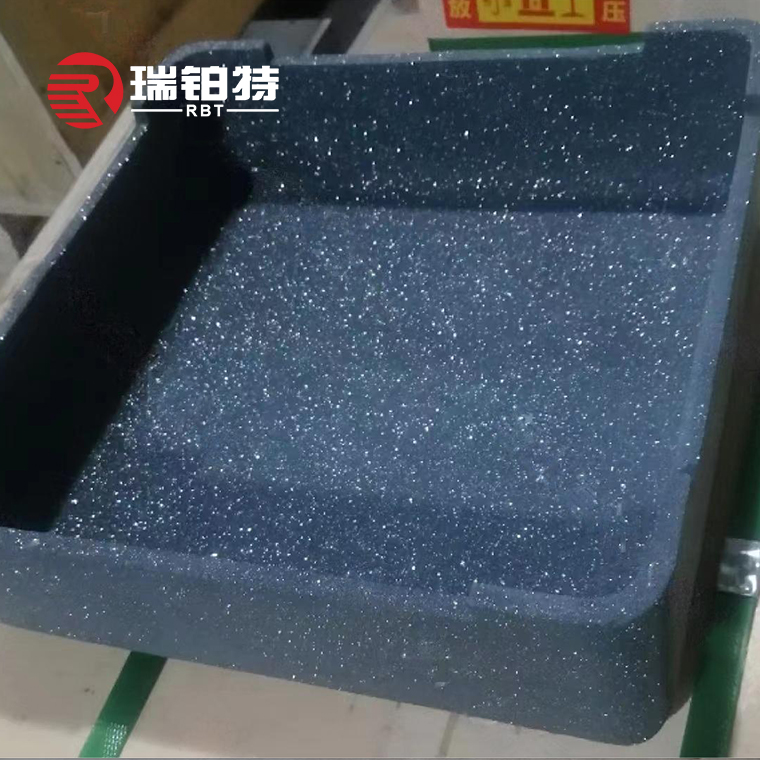

Wear-resistant Lining

Silicon Carbide Wafer Boat

Product Index

|

RBSiC(SiSiC) Products

|

||

|

Item

|

Unit

|

Data

|

|

Max Temperature of Application

|

℃

|

≤1350

|

|

Density

|

g/cm3

|

≥3.02

|

|

Open Porosity

|

%

|

≤0.1

|

|

Bending Strength

|

Mpa

|

250(20℃); 280(1200℃)

|

|

Modulus of Elastictiy

|

Gpa

|

330(20℃); 300(1200℃)

|

|

Thermal Conductivity

|

W/m.k

|

45(1200℃)

|

|

Thermal Expansion Coefficient

|

K-1*10-6

|

4.5

|

|

Moh's Hardness

|

|

9.15

|

|

Acid Alkaline-Proof

|

|

Excellent

|

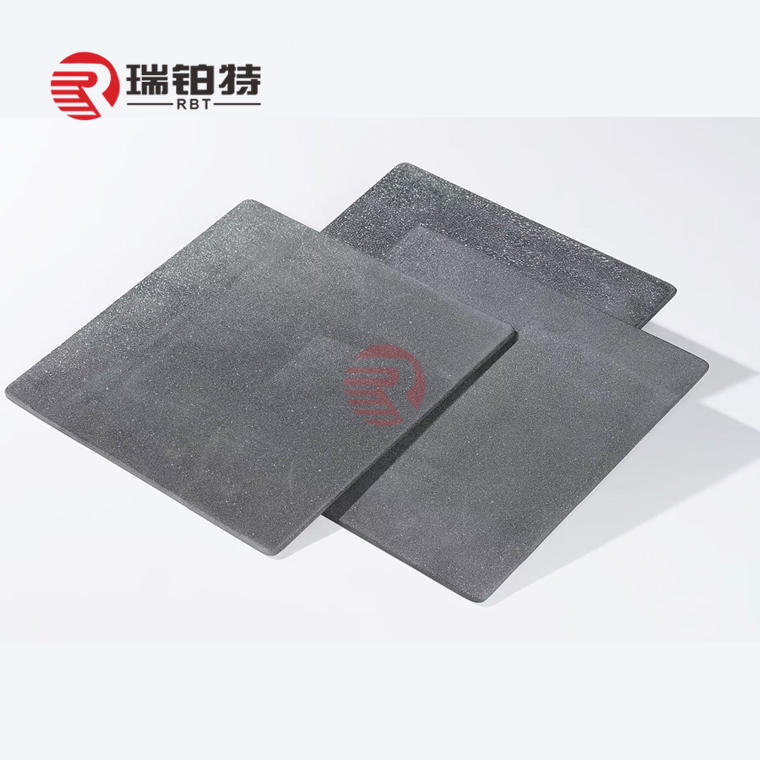

2. Pressureless sintered silicon carbide products(SSiC Products)

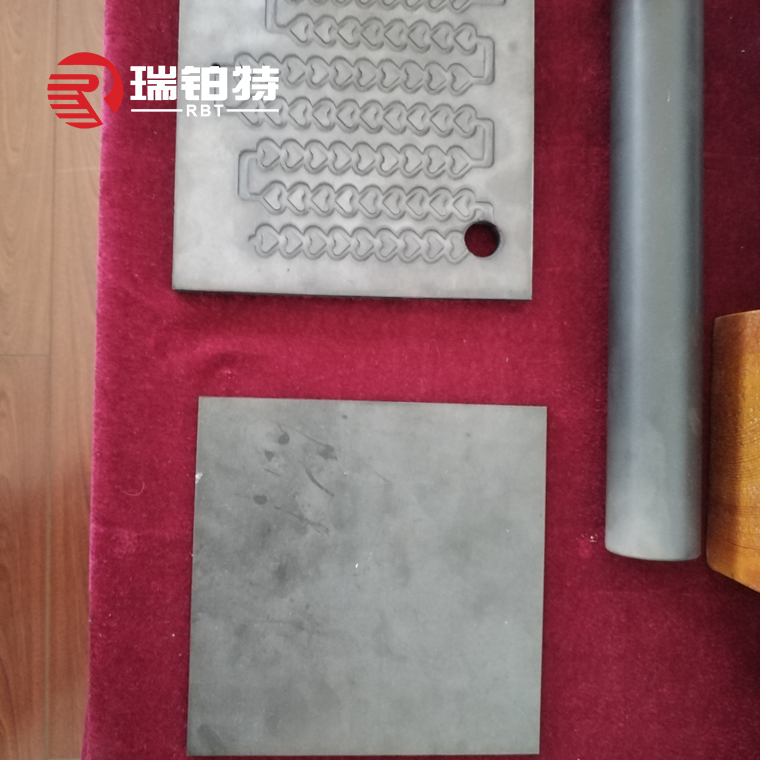

Pressureless sintered silicon carbide products are a kind of high-tech ceramic material prepared by pressureless sintering process. Its main component is silicon carbide (SiC), and a certain proportion of additives are added. Through advanced ceramic technology, it is made into non-porous, seamless, and stress-free high-density ceramics.

(1) Characteristics:

High temperature resistance: normal use at 1800℃;

High thermal conductivity: equivalent to the thermal conductivity of graphite materials;

High hardness: hardness is second only to diamond and cubic boron nitride;

Corrosion resistance: strong acid and strong alkali have no corrosion to it, and its corrosion resistance is better than tungsten carbide and aluminum oxide;

Light weight: density 3.10g/cm3, close to aluminum;

No deformation: extremely small thermal expansion coefficient,

Resistant to thermal shock: the material can withstand rapid temperature changes, thermal shock, rapid cooling and heating, and has stable performance.

(2) Main Products:

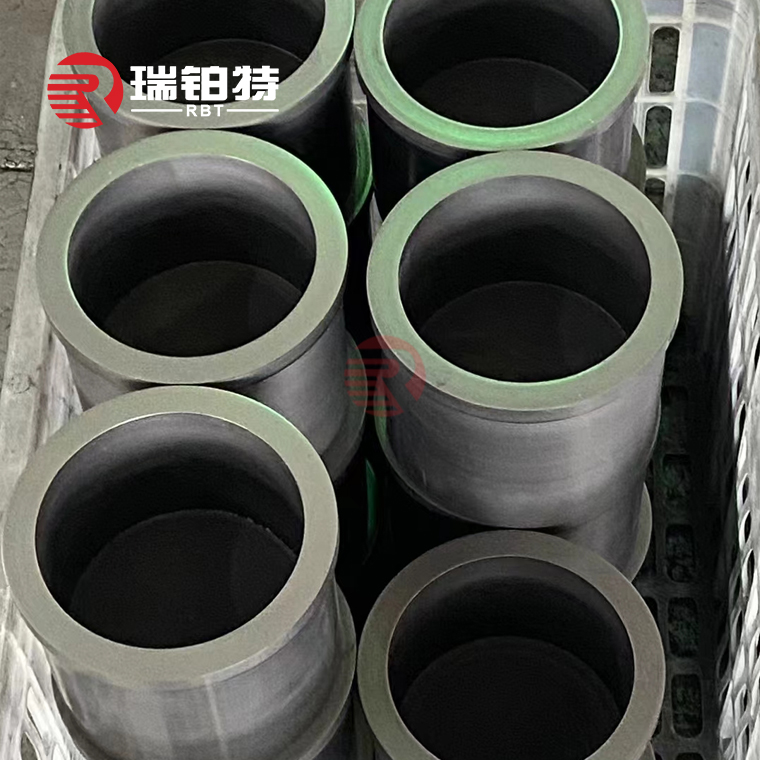

Seal rings: Pressureless sintered silicon carbide products are often used to manufacture wear-resistant and corrosion-resistant sealing rings and sliding bearings.

Mechanical parts: Including high-temperature bearings, mechanical seals, nozzles, pneumatic valves, pump bodies, fixtures, etc.

Chemical equipment: Used to manufacture corrosion-resistant pipes, storage tanks, reactors and seals.

Electronic devices: In the power industry, pressureless sintered silicon carbide is used to manufacture high-temperature resistors, electric heating elements and high-voltage switches.

Kiln furniture: Such as load-bearing structural frames, rollers, flame nozzles, cooling pipes, etc. in tunnel kilns, shuttle kilns and other industrial kilns.

Details Images

Silicon Carbide Seal Ring

Silicon Carbide Pipe

Silicon Carbide Liners

Silicon Carbide Beam

Silicon Carbide Plate

Silicon Carbide Grinding Barrel

Product Index

|

SSiC Products

|

||

|

Item

|

Unit

|

Result

|

|

Hardness

|

HS

|

≥115

|

|

Porosity Rate

|

%

|

<0.2

|

|

Density

|

g/cm3

|

≥3.10

|

|

Compressive Strength

|

Mpa

|

≥2500

|

|

Bending Strength

|

Mpa

|

≥380

|

|

Coefficient of Expansion

|

10-6/℃

|

4.2

|

|

Content of SiC

|

%

|

≥98

|

|

Free Si

|

%

|

<1

|

|

Elastic Modulus

|

Gpa

|

≥410

|

|

Max Temperature of Application

|

℃

|

1400

|

3. Recrystallized silicon carbide product(RSiC Products)

Recrystallized Silicon Carbide Products is a refractory product made of high-purity silicon carbide as raw material. Its main feature is that there is no second phase and it is composed of 100% α-SiC.

(1) Characteristics:

High hardness: Its hardness is second only to diamond, and it has extremely high mechanical strength and rigidity.

High temperature resistance: It can maintain stable performance in high temperature environment and is suitable for the temperature range of 1350~1600℃.

Strong corrosion resistance: It has high corrosion resistance to a variety of media and can maintain mechanical properties for a long time in a variety of corrosive environments.

Good oxidation resistance: It has good oxidation resistance and can work stably at high temperatures.

Good thermal shock resistance: It performs well in an environment with rapid temperature changes and is suitable for thermal shock environments.

No shrinkage during sintering: It does not shrink during the sintering process, and no residual stress will be generated to cause deformation or cracking of the product. It is suitable for the preparation of parts with complex shapes and high precision.

(2) Main Products:

Kiln furniture materials: Mainly used for kiln furniture, it has the advantages of energy saving, increasing the effective volume of the kiln, shortening the firing cycle, improving the kiln's production efficiency and high economic benefits.

Bunner nozzles: It can be used as combustion nozzle heads and is suitable for high temperature environments.

Ceramic radiation heating tubes: These heating tubes take advantage of the high temperature stability and corrosion resistance of recrystallized silicon carbide and are suitable for various high temperature industrial applications.

Component protection tubes: Especially in atmosphere furnaces, recrystallized silicon carbide products are used as component protection tubes with good high temperature and corrosion resistance.

High temperature pump bodies, pump impellers, bearings, engine housings: In the fields of automobiles, aerospace and military industries, recrystallized silicon carbide materials are made into high temperature pump bodies, pump impellers, bearings and engine housings, etc., taking advantage of their high temperature resistance, acid and alkali corrosion resistance and wear resistance.

Details Images

Silicon Carbide Shaped Parts

Silicon Carbide Plate

Silicon Carbide Roller

Silicon Carbide Beam

Silicon Carbide Protection Tubes

Kiln Furniture

Silicon Carbide Sagger

Silicon Carbide Crucible

Silicon Carbide Plate

Silicon Carbide Lgniter

Silicon Carbide Pipe

Silicon Carbide Burner

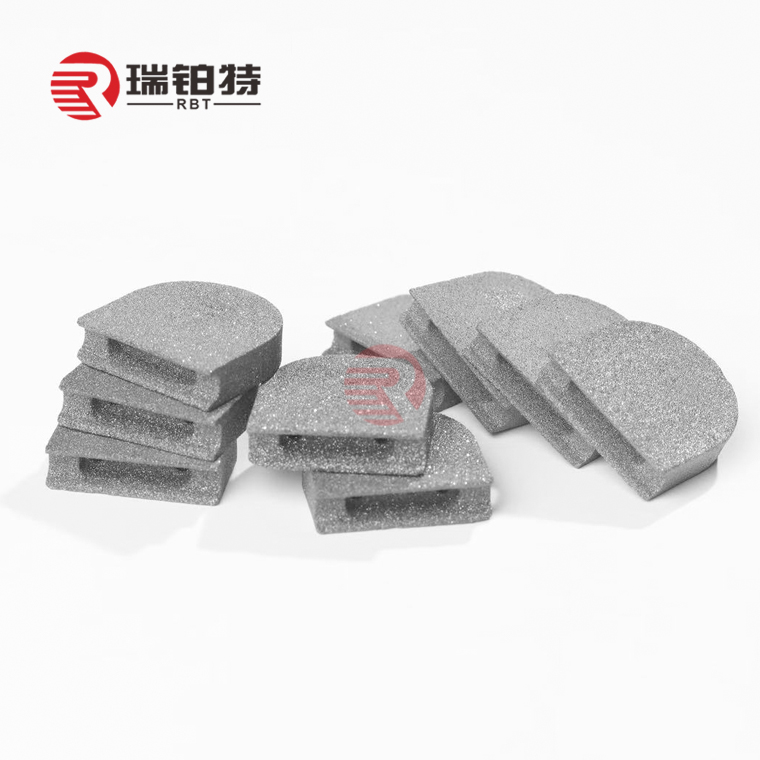

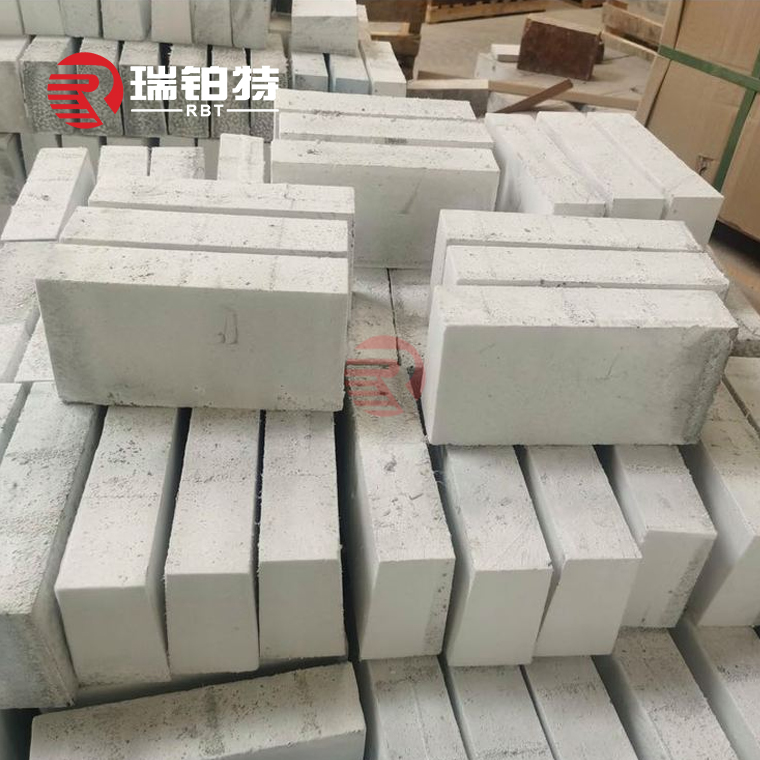

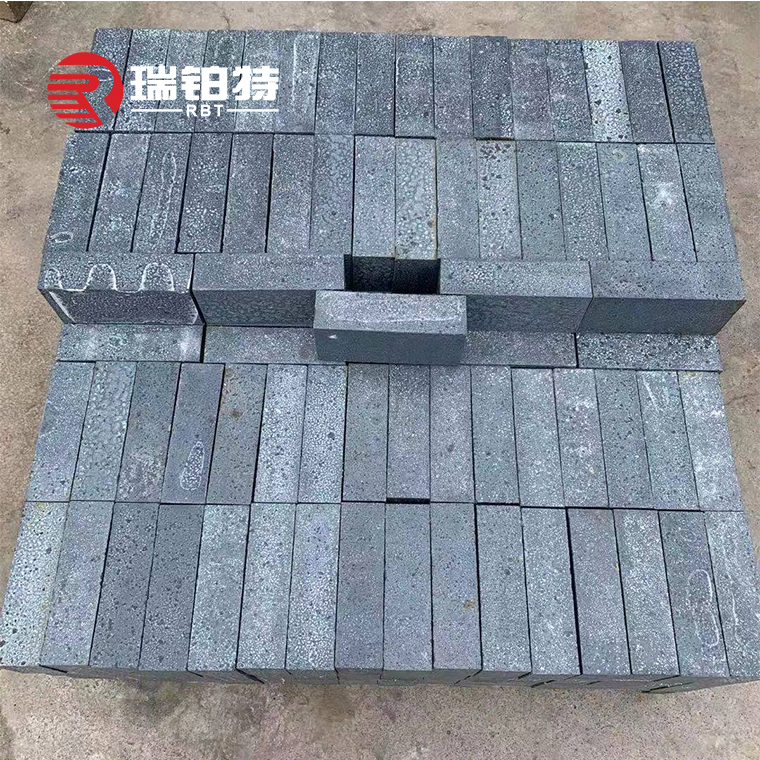

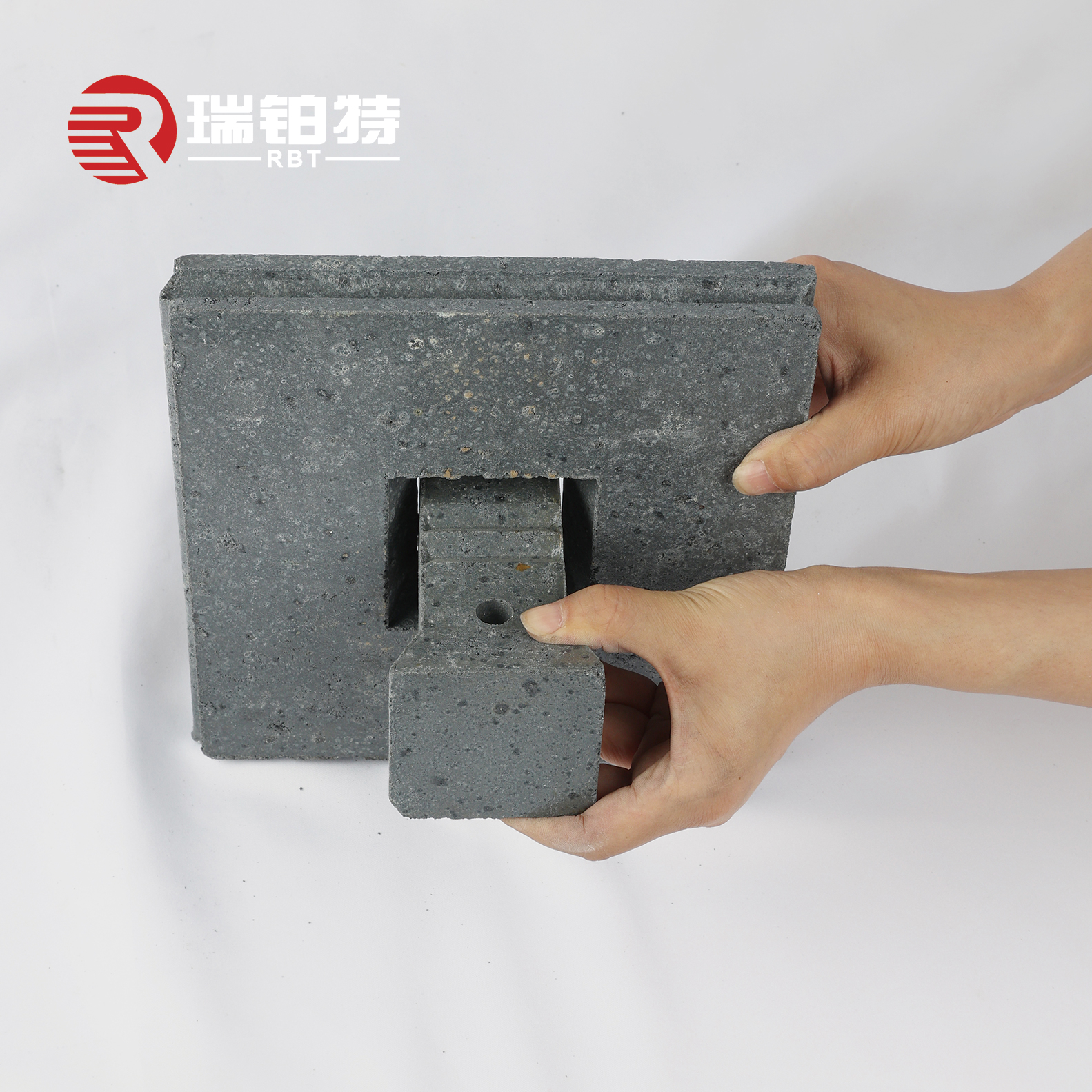

4. Silicon nitride bonded silicon carbide products(NSiC Products)

Silicon nitride bonded silicon carbide products are a material formed by adding SiC aggregate to industrial silicon powder, reacting with nitrogen at high temperature to generate Si3N4 and tightly combining with SiC particles.

(1) Characteristics:

High hardness: The Mohs hardness of silicon nitride bonded silicon carbide products is about 9, second only to diamond, and is a material with higher hardness among non-metallic materials.

High temperature strength: At high temperatures of 1200-1400℃, the strength and hardness of the material remain almost unchanged, and the maximum safe use temperature can reach 1650-1750℃.

Thermal stability: It has a small thermal expansion coefficient and high thermal conductivity, is not easy to generate thermal stress, has good thermal shock stability and creep resistance, and is suitable for extremely cold and hot environments.

Chemical stability: It is corrosion-resistant and oxidation-resistant, and can remain stable in a variety of chemical environments.

Wear resistance: It has good wear resistance and is suitable for various industrial applications with severe wear.

(2) Main Products:

Refractory bricks: widely used in electrolytic aluminum, ironmaking blast furnaces, submerged arc furnaces and other industries, with the characteristics of high temperature resistance, corrosion resistance, and erosion resistance.

Kiln furniture: used for ceramic grinding wheels, high-voltage electric porcelain, industrial kilns, etc., with good load-bearing capacity and high temperature resistance.

Special-shaped products: used in non-ferrous metallurgical casting, thermal power, submerged arc furnaces and other industries, with the characteristics of wear resistance and high temperature resistance.

Refractory parts: including thermocouple protection tubes, riser tubes, heating sleeves, etc., used in high-temperature kilns and various atmospheres, with high thermal conductivity and corrosion resistance.

Details Images

Silicon Carbide Shaped Plate

Silicon Carbide Shaped Plate

Silicon Carbide Shaped Plate

Silicon Carbide Shaped Plate

Silicon Carbide Shaped Plate

Silicon Carbide Radiation Tubes

Silicon Carbide Pipe

Silicon Carbide Shaped Plate

Silicon Carbide Shaped Parts

Silicon Carbide Protection Tubes

Silicon Carbide Plate

Silicon Carbide Bricks

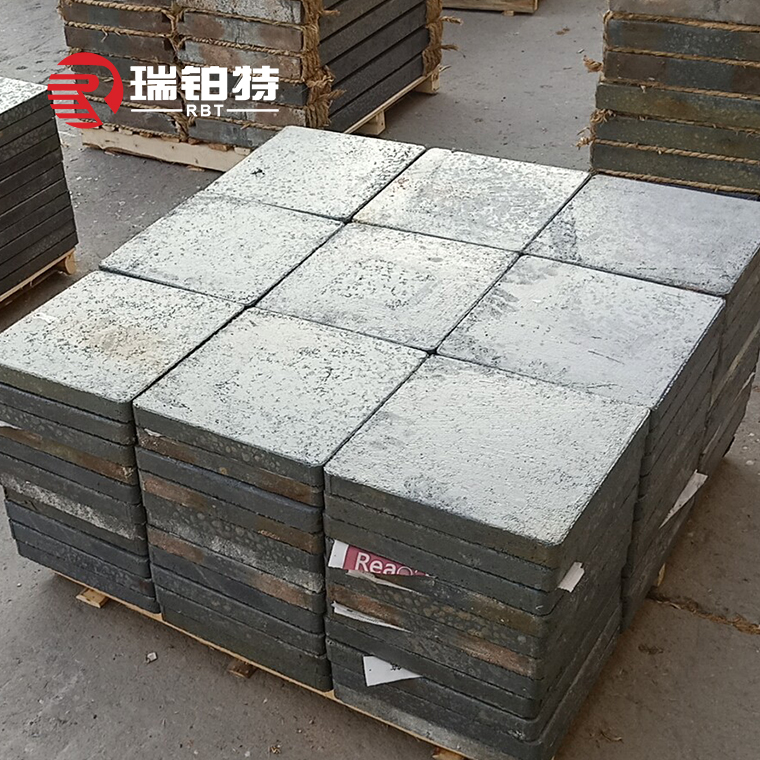

5. Oxide-bonded silicon carbide products

Oxide-bonded silicon carbide products are made by mixing silicon carbide particles with oxide powder (such as silicon dioxide or mullite), pressing and sintering at high temperature. Its characteristic is that during the sintering and use process, the oxide film is wrapped on the silicon carbide particles, which significantly improves the oxidation resistance and high temperature strength.

It has the characteristics of high high-temperature flexural strength, good thermal shock stability, high thermal conductivity, wear resistance and strong resistance to various atmosphere erosion, and is an ideal energy-saving material for industrial furnaces.

(2) Main Products:

Silicon dioxide bonded silicon carbide products: This product uses silicon dioxide (SiO2) as the binding phase. Usually 5%~10% of silicon dioxide powder or quartz powder is mixed with silicon carbide (SiC) particles. Sometimes a flux is added. After pressing and forming, it is fired in a general kiln. Its characteristic is that during the firing and use process, the silicon dioxide film is wrapped on the silicon carbide particles, which significantly improves the oxidation resistance and high temperature strength. This product is widely used in kiln shelves for firing porcelain (>1300℃), and its service life is more than

doubled that of clay-bonded silicon carbide products.

Mullite bonded silicon carbide products: This product adds α-Al2O3 powder and silicon dioxide powder to the silicon carbide ingredients. After pressing and forming, Al2O3 and SiO2 are combined to form mullite during the sintering process. During use, the silicon dioxide formed by the oxidation of silicon carbide partially forms mullite with Al2O3. This material has good thermal shock stability and is widely used in the manufacture of porcelain saggers and shelves.

Details Images

Silicon Carbide Plate

Silicon Carbide Bricks

Silicon Carbide Plate

SiC Microcrystalline Pipe

SiC Microcrystalline Board

SiC Microcrystalline Board

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.