Superior High Alumina Bricks For Refractory

description

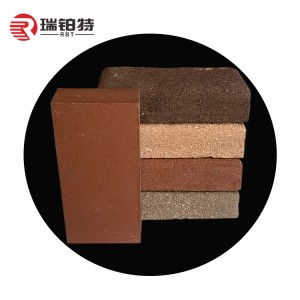

High aluminum bricks refer to alumina content in more than 48% of a neutral refractory material, according to the different aluminum content, mainly divided into three levels: Ⅰ(Al2O3≥75%); Ⅱ(60%≤Al2O3<75%); Ⅲ(48%≤Al2O3<60%).

Features

1. Refractoriness

The refractoriness of high-alumina bricks is higher than that of clay bricks and semi-silica bricks, reaching 1750~1790°C, which is a high-grade refractory material.

2. Load softening temperature

Because the Al2O3 in high alumina products is high, the amount of impurities is less, and the formation of fusible glass is less, the softening temperature under load is higher than that of clay bricks. However, because mullite crystallization does not form a network structure, the softening temperature under load is still not as high as that of silica bricks.

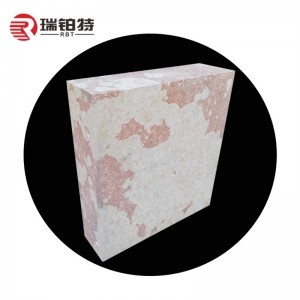

3. Slag resistance

There are more Al2O3 in high alumina bricks, which are close to neutral refractory materials, and can resist the erosion of acid slag and alkaline slag. Because it contains SiO2, the ability to resist alkaline slag is weaker than that of acid slag.

Production Process

The production process of high-alumina bricks and multi-clinker clay bricks is similar. The difference is that the proportion of clinker in the ingredients is relatively high, which can be as high as 90-95%. Higher, such as Ⅰ, Ⅱ and other high-alumina bricks are generally fired at 1500-1600 ℃ when fired in a tunnel kiln.

Application

It is mainly used for laying the lining of blast furnace, hot blast stove, electric arc furnace top, blast furnace, reverberatory furnace and rotary kiln. In addition, high alumina bricks are also widely used as open hearth furnace regenerative lattice brick, plug and nozzle for feed system, and so on.

Product Index

| INDEX PRODUCT | SK-35 | SK-36 | SK-37 | SK-38 | SK-39 | SK-40 |

| Refractoriness(℃) ≥ | 1770 | 1790 | 1820 | 1850 | 1880 | 1920 |

| Bulk Density(g/cm3) ≥ | 2.25 | 2.30 | 2.35 | 2.40 | 2.45 | 2.55 |

| Apparent Porosity(%) ≤ | 23 | 23 | 22 | 22 | 21 | 20 |

| Cold Crushing Strength(MPa) ≥ | 40 | 45 | 50 | 55 | 60 | 70 |

| @1400°×2hPermanent Linear Change(%) | ±0.3 | ±0.3 | ±0.3 | ±0.3 | ±0.2 | ±0.2 |

| Refractoriness Under Load(℃) ≥ | 1420 | 1450 | 1480 | 1520 | 1550 | 1600 |

| Al2O3(%) ≥ | 48 | 55 | 62 | 70 | 75 | 80 |

| Fe2O3(%) ≤ | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 1.8 |