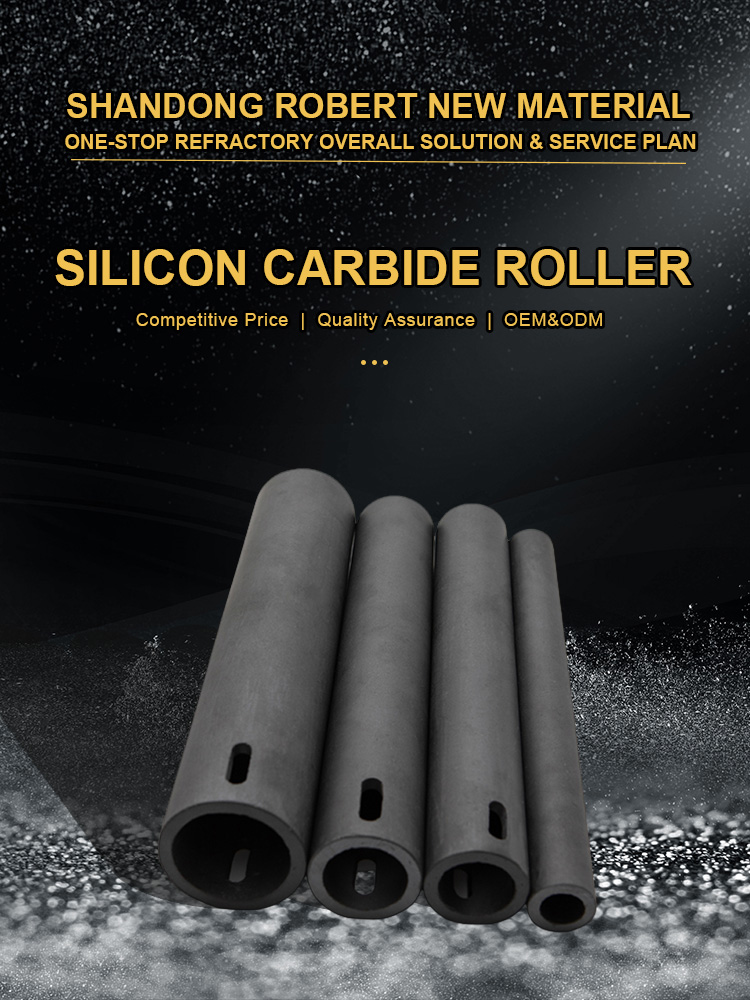

Supply OEM/ODM Standard Dimension Reaction Bonded Silicon Carbide Ceramic Sisic roller

Fast and good quotations, informed advisers to help you choose the correct product that suits all your needs, a short production time, responsible quality control and different services for paying and shipping affairs for Supply OEM/ODM Standard Dimension Reaction Bonded Silicon Carbide Ceramic Sisic roller, Our skilled technological team might be wholeheartedly at your service. We sincerely welcome you to definitely stop by our web site and business and send out us your inquiry.

Fast and good quotations, informed advisers to help you choose the correct product that suits all your needs, a short production time, responsible quality control and different services for paying and shipping affairs for Refractory Ceramics and Kiln Furniture, So that you can utilize the resource from the expanding info in international trade, we welcome shoppers from everywhere on-line and offline. In spite of the good quality solutions we offer, effective and satisfying consultation service is supplied by our specialist after-sale service team. Product lists and detailed parameters and any other info weil be sent to you timely for your inquiries. So please make contact with us by sending us emails or call us if you have any questions about our corporation. ou may also get our address info from our web page and come to our company to get a field survey of our merchandise. We are confident that we are going to share mutual achievement and create strong co-operation relations with our companions in this marketplace. We’re searching forward for your inquiries.

Product Information

Silicon carbide rollers are a new type of ceramic rollers used in roller kilns. They are important components in roller kilns and are mainly used to transport ceramic or glass products. The application scenarios of rollers require that the material of the rollers should be resistant to high temperatures and heat and also have an anti-oxidation effect and high heat resistance. At the same time, when the rollers are continuously running in a high-temperature environment, they should maintain a small deformation under the weight of the rollers and the load of the products, so that the products can move in a straight line on the rollers without failure.

Features

Silicon carbide rollers have excellent high-temperature flexural strength and oxidation resistance, and will not bend or break during long-term high-temperature use. They are superior to alumina rollers in terms of thermal shock stability and high-temperature load resistance.

Details Images

Application

| RBSIC(SiSiC) Roller | SSiC Roller |

| Application: Roller kiln lithium battery positive and negative electrode materials transmission, magnetic materials, electronic ceramic powder, daily ceramics, refractory materials and other transmission sintering process, is the most critical material in the roller kiln, plays the role of bearing and transmitting products in the kiln. | Application: Used in the high temperature area of roller kiln to ensure that the fired products can pass safely and smoothly. |

Package&Warehouse

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

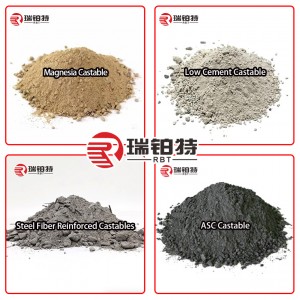

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Robert`s products are widely used in high-temperature kilns such as non-ferrous metals, steel, building materials and construction, chemical, electric power, waste incineration, and hazardous waste treatment. They are also used in steel and iron systems such as ladles, EAF, blast furnaces, converters, coke ovens, hot blast furnaces; non-ferrous metallurgical kilns such as reverberators, reduction furnaces, blast furnaces, and rotary kilns; building materials industrial kilns such as glass kilns, cement kilns, and ceramic kilns; other kilns such as boilers, waste incinerators, roasting furnace, which have achieved good results in using. Our products are exported to Southeast Asia, Central Asia, Middle East, Africa, Europe, Americas and other countries, and has established a good cooperation foundation with multiple well-known steel enterprises. All employees of Robert sincerely look forward to working with you for a win-win situation.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

Are you a manufacturer or a trader?

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

How do you control your quality?

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

What is your delivery time?

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Do you provide free samples?

Of course, we provide free samples.

Can we visit your company?

Yes, of course, you are welcome to visit RBT company and our products.

What is the MOQ for trial order?

There is no limit, we can provide the best suggestion and solution according to your situation.

Why choose us?

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.

Fast and good quotations, informed advisers to help you choose the correct product that suits all your needs, a short production time, responsible quality control and different services for paying and shipping affairs for Supply OEM/ODM Standard Dimension Reaction Bonded Silicon Carbide Ceramic Sisic roller, Our skilled technological team might be wholeheartedly at your service. We sincerely welcome you to definitely stop by our web site and business and send out us your inquiry.

Supply OEM/ODM Refractory Ceramics and Kiln Furniture, So that you can utilize the resource from the expanding info in international trade, we welcome shoppers from everywhere on-line and offline. In spite of the good quality solutions we offer, effective and satisfying consultation service is supplied by our specialist after-sale service team. Product lists and detailed parameters and any other info weil be sent to you timely for your inquiries. So please make contact with us by sending us emails or call us if you have any questions about our corporation. ou may also get our address info from our web page and come to our company to get a field survey of our merchandise. We are confident that we are going to share mutual achievement and create strong co-operation relations with our companions in this marketplace. We’re searching forward for your inquiries.