Zirconia Beads

Product Information

Zirconia beads are a high-performance grinding medium, mainly made of micron- and sub-nano-level zirconium oxide and yttrium oxide. It is mainly used for ultra-fine grinding and dispersion of materials that require "zero pollution" and high viscosity and high hardness. It is widely used in electronic ceramics, magnetic materials, zirconium oxide, silicon oxide, zirconium silicate, titanium dioxide, pharmaceutical food, pigments, dyes, inks, special chemical industries and other fields.

Features:

High density: The density of zirconia beads is 6.0g/cm³, which has extremely high grinding efficiency and can increase the solid content of materials or increase the flow rate of materials.

High toughness: It is not easy to break during high-speed operation, and its wear resistance is 30-50 times that of glass beads.

Low pollution: It is suitable for occasions requiring "zero pollution" because its material will not cause pollution to the material.

High temperature and corrosion resistance: The strength and hardness are almost unchanged at 600℃, which is suitable for grinding operations in high temperature environments.

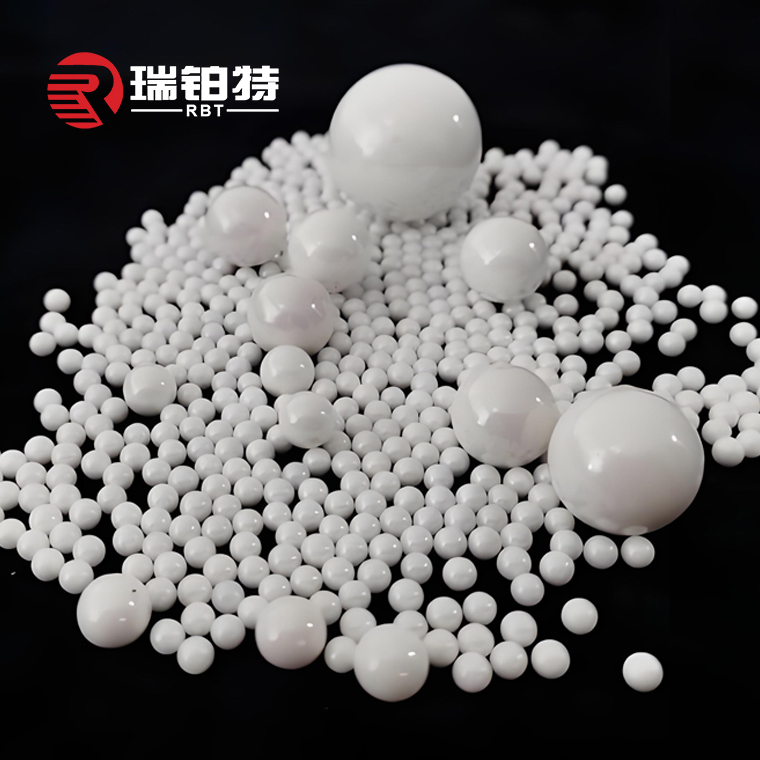

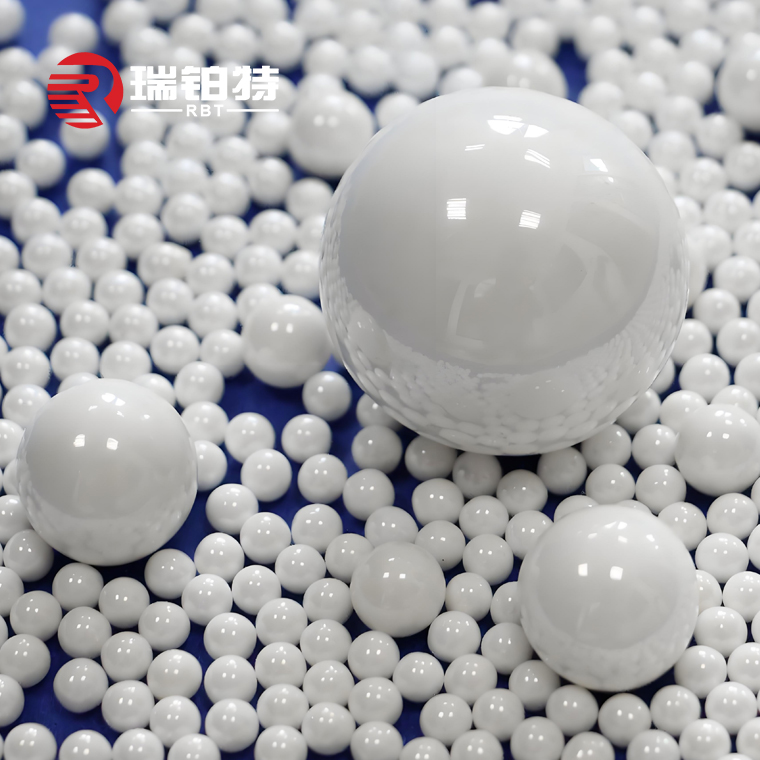

Good sphericity and surface smoothness: The sphere has good overall roundness, smooth surface, and pearl-like luster, suitable for various grinding equipment.

Details Images

The size of zirconia beads ranges from 0.05mm to 50mm. Common sizes include 0.1-0.2mm, 0.2-0.3mm, 0.3-0.4mm, 0.4-0.6mm, 0.6-0.8mm, 0.8-1.0mm, 1.8-2.0mm, etc., suitable for different grinding needs.

Fine grinding: Smaller zirconia beads (such as 0.1-0.2mm) are suitable for fine grinding, such as grinding of electronic materials or nanomaterials.

Ordinary grinding: Medium zirconia beads (such as 0.4-0.6mm, 0.6-0.8mm) are suitable for grinding ordinary materials, such as coatings, paints, etc.

Bulk material grinding: Larger zirconia beads (such as 10mm, 12mm) are suitable for grinding large and hard materials.

Product Index

|

Item |

Unit | Specification |

|

Composition |

wt% |

94.5% ZrO 25.2% Y2O3 |

|

Bulk Density |

Kg/L |

>3.6(Φ2mm) |

|

Specific Density |

g/cm3 |

≥6.02 |

|

Hardness |

Moh's |

>9.0 |

| Elastic Modulus |

GPa |

200 |

| Thermal Conductivity |

W/m.K |

3 |

| Crushing Load |

KN |

≥20 (Φ2mm) |

| Fracture Toughness | MPam1-2 |

9 |

|

Grain Size |

µm |

≤0.5 |

| Wear Loss | ppm/h |

<0.12 |

Application

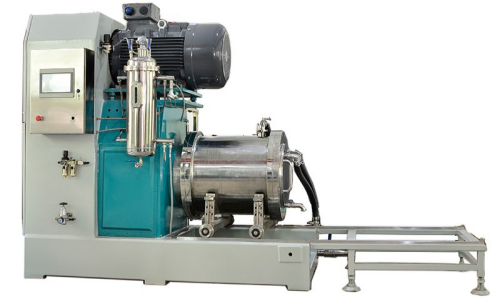

Zirconia beads are particularly suitable for vertical stirred mills, horizontal rolling ball mills, vibration mills and various high-speed wire pin sand mills, etc., and are suitable for various requirements and cross-contamination of slurries and powders, dry and wet ultrafine dispersion and grinding.

The application areas are as follows:

1. Coatings, paints, printing and inkjet inks

2. Pigments and dyes

3. Pharmaceuticals

4. Food

5. Electronic materials and components, such as CMP slurries, ceramic capacitors, lithium iron phosphate batteries

6. Chemicals, including agrochemicals, such as fungicides, pesticides

7. Minerals, such as TiO2 GCC and zircon

8. Biotechnology (DNA and RNA separation)

9. Flow distribution in process technology

10. Vibration grinding and polishing of jewelry, gemstones and aluminum wheels

Sand Grinder

Sand Grinder

Mixing Mill

Sand Grinder

Cosmetic

Pesticides

Biotechnology

Electronic Materials

Pesticides

Package

25kg/Plastic Drum; 50kg/Plastic Drum or according to customer's requirements.

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.